Single Phase vs 3-Phase Solar Inverter

Mar 20, 2025 · A 3-phase solar inverter sends the electricity evenly across the 3 wires which minimises the voltage drop problem associated with a single phase power supply. It needs to

AN-CM-270 Design and Implementation of a Single

Jan 7, 2025 · This application note explores the use of GreenPAK ICs in power electronics applications and will demonstrate the implementation of a single-phase inverter using various

Single-Phase 15-Level Inverters for Uninterruptible Power Supply

Sep 28, 2023 · An uninterruptible power supply (UPS) is commended unit or even necessary for consumers'' electronic devices in the individual, industry, and critical categories to protect them

Single to Three Phase Inverter

A single to three-phase inverter is an electronic device that converts single-phase AC (Alternating Current) power into three-phase AC power. This conversion is essential in applications where

Understanding Split Phase Inverters: A Comprehensive Guide

By generating two out-of-phase waveforms, split phase inverters facilitate the operation of single-phase AC equipment that requires a 240-volt power supply. One of the primary applications of

Research of Full Digit Single-phase Inversion Power Supply

Jan 1, 2012 · With the increasing need of high quality power supply resulting from the use of electric appliances day by day, research on high-performance PWM inverter is gaining more

A Novel Interphase-Bridging Single-Phase Inverter for

Apr 25, 2024 · The back-to-back railway energy router (BTB-RER) has been a research hotspot in the electrified railways, in order to balance traction network interphase power, reuse braking

How does Single-Phase Inverter Work on a Three-Phase

May 31, 2023 · Technical aspect of connecting single-phase inverter to a three-phase supply Connecting a three-phase inverter with a three-phase grid connection is always the preferred

Design of single phase inverter

Sep 2, 2020 · Abstract In this paper, the SPWM inverter based on STC12C5A60S2 single-chip microcomputer is used. The system can convert the input single-phase AC power supply into

Design of single-phase online uninterruptible power supply based

Mar 1, 2021 · Abstract According to the principle of UPS, an AC sine wave online uninterruptible power supply based on STM32 is designed. The system adopts mains power, outputs

Inverter and Types of Inverters with their

3 days ago · Related Post: Difference between Inverter & UPS – Uninterruptible Power Supply Different Types of Inverters Inverters are classified into many

Single Phase Inverter

Jul 23, 2025 · Some industrial applications of inverters are for adjustable-speed AC drives, induction heating, stand by air-craft power supplies, UPS for computers, HVDC transmission

Power Inverters: What Are They & How Do They

Dec 17, 2019 · This is just to understand the working principle of an inverter. Practically, inverter never works like this and it doesn''t have rotating parts.

6 FAQs about [Single-phase inverter power supply]

What is a single phase output inverter?

Single phase output inverters are commonly used in residential and small-scale commercial applications where the power requirement is relatively modest. They are versatile and can be employed in various scenarios, including off-grid systems, backup power systems, and in conjunction with renewable energy sources like solar panels.

How does a single phase inverter work?

The single phase inverter actually does more than just convert from 1 phase power to 3 phase power supply. The inverter controls the output waveform to allow the speed to be controlled by changing the frequency to the motor from 0-200Hz.

Can a single phase frequency inverter be installed on single phase power supplies?

This paper is intended to be a general guide only for the installation of single phase frequency inverters on single phase power supplies. The two supply voltages discussed will include 220V (230V, 240V) and 480V Single Wire Earth Return (SWER) systems.

How to install a single phase inverter?

The installation of single phase inverter is simple as shown. Speed control can be manually using the controls provided or remote speed potentiometer. A Pressure control system can be easily achieved using the single phase inverters internal PID control and an external pressure transducer.

Does a 3 phase inverter need a 1 phase power supply?

Since the inverter acts as an inverter and produces a 3 Phase power supply from a 1 Phase supply, the current is expected to be higher on the input then the output. It is therefore important to determine what level of supply current is required for the intended motor.

Can a frequency inverter convert 1 phase to 3 phase?

The general rule to remember is that a frequency inverter can convert single phase into three phase power but, it cannot provide a higher voltage out than what you put in. Therefore if you only have a 220V 1phase power supply input, you cannot get three phase 415V output. It will only provide 220V 3 phase output.

Learn More

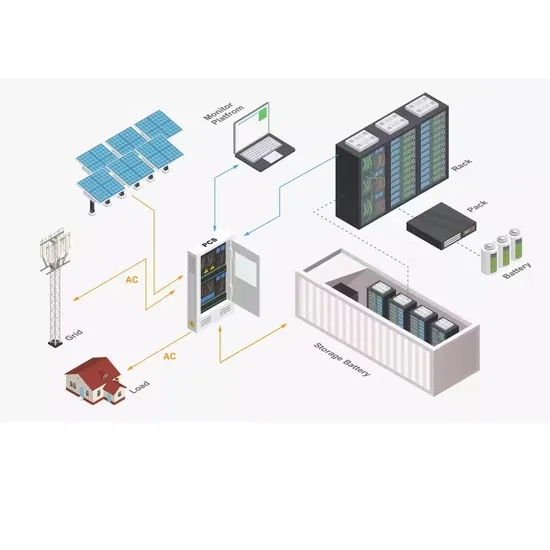

- Solar inverter power supply system

- Photovoltaic power supply light storage inverter

- Thailand communication base station inverter hybrid power supply

- Kyiv Photovoltaic Power Inverter Supply

- Construction of inverter grid-connected power supply for China-Africa communication base station

- How big of an inverter can a 48ah power supply be

- Single-phase inverter output power design

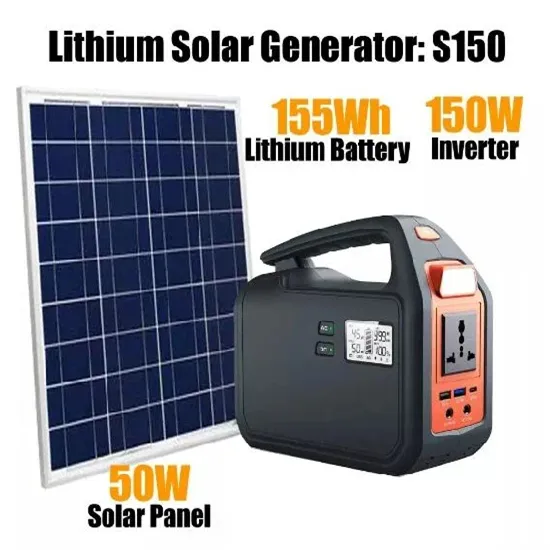

- Photovoltaic panels directly supply power to the inverter

- Chile photovoltaic energy storage 15kw inverter power supply

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.