How to convert a conventional generator to a pure sine

Apr 2, 2025 · The pure sine wave generators look essentially the same hardware as a conventional generator (motor, exhaust, fuel tank, etc.), just often with more casing for noise

How to Check If Your Inverter Is Pure Sine Wave:

Mar 11, 2025 · In this guide, you''ll learn a few simple ways to test your inverter''s output, recognize the warning signs of a substandard waveform, and learn

DIY SG3525 pure sine wave inverter circuit design-EEWORLD

First disconnect the jumper JP1 to open the circuit, adjust VR1 to make the output sine wave not clipped; adjust VR2 to make the upper and lower half waves of the sine wave connect

Pure Sine Wave Inverters vs. Modified Sine Wave Inverters: A

Jun 23, 2025 · In the realm of power inverters, understanding the distinctions between pure sine wave and modified sine wave types is crucial for making informed decisions about energy

Use a line conditioner to convert modified to pure sine wave?

Jul 29, 2013 · Dell claims it will stabilize voltage, not the wave. Sine wave is, basically, Hertz. A ''pure sine'' inverter very closely replicates the ''waves'' in which AC current flows while a

SG3525 PWM Inverter Circuit Diagram and it''s Working

Sep 9, 2024 · The SG3525 inverter circuit offers a versatile and efficient solution for generating both modified and pure sine wave AC outputs. It operates using a basic PWM technique to

modified sine wave to true sine waveform conversion

Aug 31, 2015 · I am now in search of something, anything, that would easily and simply convert modified sine waveform to a pure or true sine wave, ANY IDEAS? I have considered

Design of Pure sine wave inverter

May 8, 2024 · The design methodology covers the selection of suitable components such as power transistors, capacitors. The construction phase layout of the circuit board, assembly of

SG3525 for Inverter | Page 3 | diyAudio

Mar 25, 2007 · For pure sine wave inverter, you require 2 stage configuration- first boost section, from 12/24v dc to 350v dc and for that you require 2 pins of Pic micro controller to drive

How to Make a Pure Sine Wave Inverter Using the EGS002

Here''s the list of primary components required: EGS002 Pure Sine Wave Inverter Module – The brain of the inverter. MOSFETs (4–6 units): IRF3205 or IRFZ44N MOSFETs for switching.

Dc-Ac pure sive inverter design

Sep 8, 2004 · Hello out there, I plan to make the following dc-ac inverter; 1000watts or less, 12vdc car battery will be used; 12dc will be converted to 650vdc peak to peak; PWM freq. of about

Pure sine wave generation in battery-less solar system using

Jun 1, 2024 · If the system involves an inverter generating an electrical signal fed into a motor, and the mechanical output from the motor needs to be converted back into a pure sine wave, it

Converting a modified sine wave to pure?

Feb 26, 2010 · I have an integrated system in my boat where I just press a button to invert 240v to all sockets. That''s fine but a modified sine wave won''t run an induction hob and I already have

H Bridge Inverter Circuit using IC SG3525 and

Jan 9, 2025 · Conclusion The SG3525-based H-bridge inverter circuit is a reliable and efficient solution for converting DC voltage to AC power. With features

6 FAQs about [3525 inverter converted to pure sine wave]

What is a pure sine wave inverter circuit diagram?

The pure sine wave inverter circuit diagram using SG3525 consists of several basic components, including the SG3525 IC itself, a power MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor), a step-up transformer, a filter capacitor, and an output socket. The SG3525 IC receives a DC input voltage and generates a PWM signal.

Can a sg3525 inverter produce a real sine wave equivalent output?

However even for an SPWM, the RMS value will need to be correctly set initially in order to produce the correct voltage output at the output of the transformer. Once implemented one can expect a real sine wave equivalent output from any SG3525 inverter design or may be from any square wave inverter model.

How does the sg3525 inverter work?

The SG3525 inverter circuit offers a versatile and efficient solution for generating both modified and pure sine wave AC outputs. It operates using a basic PWM technique to regulate the output voltage, making it suitable for powering various electronic devices.

Are all sine wave inverters created equal?

However, not all inverters are created equal. One type of inverter that produces a high-quality sine wave output is the pure sine wave inverter. The SG3525 is a popular PWM (Pulse Width Modulation) controller that can be used to build a pure sine wave inverter.

Can a sine wave inverter output match a square wave output?

Although the modified squarewave or sine wave output could be OK with its RMS property and reasonably suitable for powering most electronic equipment, it can never match the quality of a pure sine wave inverter output.

How do you chop a sg3525 waveform?

The "chopping" is done by feeding a calculated PWM to the gates of the FET via a BJT buffer stage. A typical circuit design for converting the SG3525 waveform into a pure sine wave waveform is shown below. This design is actually an universal design which may be implemented for upgrading all square wave inverters into sine wave inverters.

Learn More

- Pure sine wave lithium battery inverter

- Bangladesh pure sine wave inverter manufacturer

- Smallest 12v pure sine wave inverter

- Bridgetown pure sine wave 20kw inverter enterprise

- Pure sine wave inverter 500

- 24V to 220V inverter pure sine wave

- Middle East pure sine wave 20kw inverter company

- San Diego Pure Sine Wave Inverter Company

- Pure sine wave inverter 48v60v72 universal

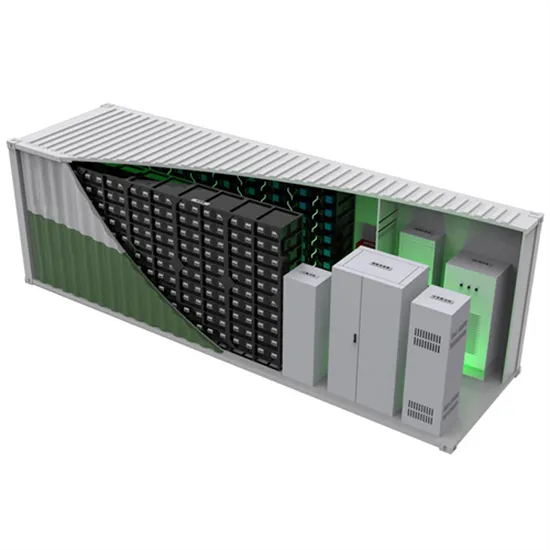

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.