The Key Components of Battery Energy Storage Systems (BESS)

Aug 18, 2025 · Understand battery energy storage system components and how their design impacts the efficiency and reliability of BESS including diagrams.

Research on modeling and grid connection stability of large

Aug 1, 2022 · Literature [7] proposed a scheme of modular energy storage battery grid connection, and adopted a control strategy combining quasi-proportional resonance control

A Battery Strings Circulating Current Blocking Method for Battery

Mar 20, 2025 · Circulating current between paralleled battery strings within a Battery Energy Storage System (BESS) can significantly affect system efficiency, battery life, a

Series, Parallel or Series and Parallel Battery Banks

Dec 14, 2020 · The figure 1 series connection DOES NOT increase your amp hour capacity. This series connection only increases the total voltage (6V+6V = 12V) and the total stored energy

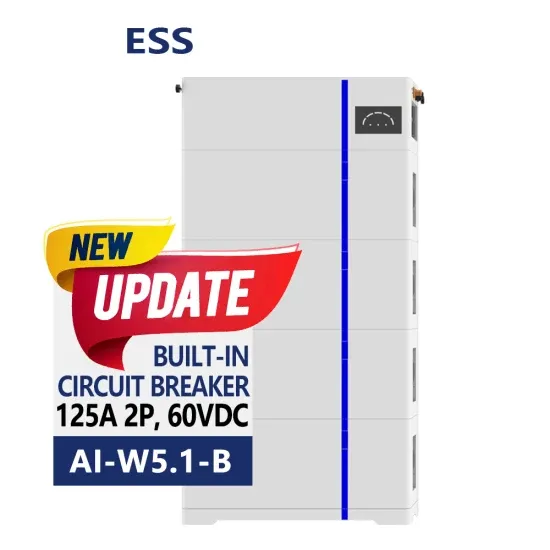

PowerMaster Smart String Energy Storage System

Jun 26, 2024 · Do not expose the battery to high temperature environments or around heat-generating equipment, such as high temperature sunlight, sources of ignition, transformers,

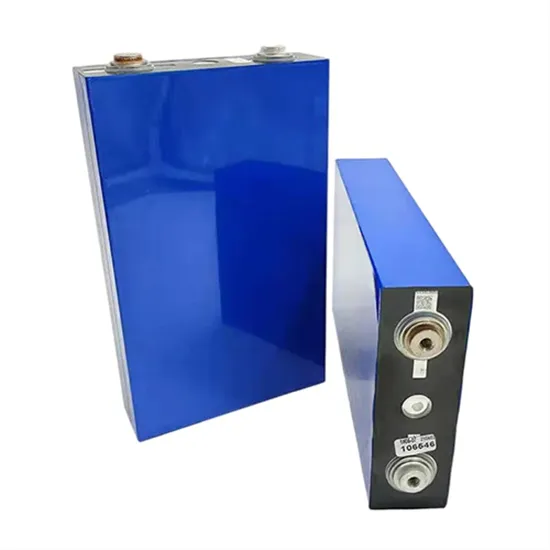

A review of battery energy storage systems and advanced battery

May 1, 2024 · Lithium batteries are becoming increasingly important in the electrical energy storage industry as a result of their high specific energy and energy density. The literature

Series vs Parallel Battery Configurations: Understanding the

May 1, 2025 · Matching voltage across all batteries is a must, and larger battery packs can become harder to wire. Series-Parallel Battery Configurations: Combining the Best of Both

SMART STRING ENERGY STORAGE SYSTEM

*1 Test conditions: 100% depth of discharge (DoD), 0.2C rate charge & discharge at 25°C, at the beginning of service life. *2 CAN is for communication between ESSs in parallel scenarios

Number of outdoor energy storage battery strings

Optimised battery storage with HD-Wave technology Single string design for inverters up to 5kW AC Record-breaking 99% weighted efficiency with up to 300% DC oversizing, for higher

Grid-connected battery energy storage system: a review on

Aug 1, 2023 · With a comprehensive review of the BESS grid application and integration, this work introduces a new perspective on analyzing the duty cycle of BESS applications, which

The Tanktwo String Battery™ for Electric Ca

Mar 30, 2021 · STRING BATTERY TM ced inside a battery enclosure in random order. The individual cells and the enclosure form a dense, random electrical connection network that can

Battery energy storage

Mar 15, 2024 · Introduction In today''s power systems, growing demand, aging infrastructure and system constraints, as well as the increasing renewable energy portfolio, have amplified the

The Tanktwo String Battery™ for Electric Ca

Mar 30, 2021 · STRING BATTERY TM A string battery is a type of rechargeable battery that consists of many individual electrochemical cells placed inside a battery enclosure in random

What Are the Types of Energy Storage Systems?

Apr 22, 2024 · If you''re curious about energy storage, you''re in the right place! In this guide, we''ll explore the different types of energy storage systems that are

Connecting Batteries Together For More Battery

Nov 13, 2023 · Alternative Energy Tutorial about connecting batteries together for more battery storage including batteries connected in series and in parallel

Energy Storage Connector | Battery Connectors

Jul 25, 2025 · Applications: Energy storage connectors provide a safe, reliable and efficient connection between energy storage systems and other electrical

Energy Storage Battery Grid Connection Methods: A 2024

Ever wondered how those giant battery farms power your Netflix binge during a blackout? Let''s crack open the energy storage battery grid connection method playbook and see how these

6 FAQs about [Connection method of string energy storage battery]

What is a battery energy storage system?

Battery energy storage systems provide multifarious applications in the power grid. BESS synergizes widely with energy production, consumption & storage components. An up-to-date overview of BESS grid services is provided for the last 10 years. Indicators are proposed to describe long-term battery grid service usage patterns.

What is battery energy storage system (BESS)?

Battery energy storage system (BESS) has been applied extensively to provide grid services such as frequency regulation, voltage support, energy arbitrage, etc. Advanced control and optimization algorithms are implemented to meet operational requirements and to preserve battery lifetime.

What is a string battery?

consists of many series connected cell strings.string battery technology removes the need for over-dimensioning of EV batteries. Traditionally over-engineering has been done for se such as to meet a minimum batteryCELL STATIONCell stations primarily per

Why do EV batteries need a string cell?

fits for manufacturers of EVs and EV batteries. The easy replacement of string cells allows for wider manufacturing tolerances, for example opening up the possibility to use cheaper battery cells, as the lifetime of a single strin cell does not have to be guaranteed for years. Hence EV batteries are easier to design, less expensive to pro

What is string cell battery technology?

ar and high peak loads on the electricity grid. String cell battery technology allows the depleted cells to be swapped for fully arged cells in a process called cell swapping. Cell swapping differs from traditional battery pack swapping echnologies in that only the cells are swapped. Swapping cells in a string battery typically takes less ti

How long does a string battery take to charge?

the string battery charge within a few minutes. This is done without the problems typically associated with fast charging, such as increased battery w ar and high peak loads on the electricity grid. String cell battery technology allows the depleted cells to be swapped for fully

Learn More

- Photovoltaic energy storage battery series connection method

- Lithium battery energy storage grid connection

- Lithium battery energy storage for communication base stations

- Costa Rica Portable Energy Storage Battery Company

- Andorra industrial energy storage battery brand

- Energy storage battery 400 ampere hours

- Moscow communication base station energy storage battery design

- How much does it cost to transport lithium battery energy storage cabinets by air

- The cost of 1 kWh of photovoltaic energy storage battery

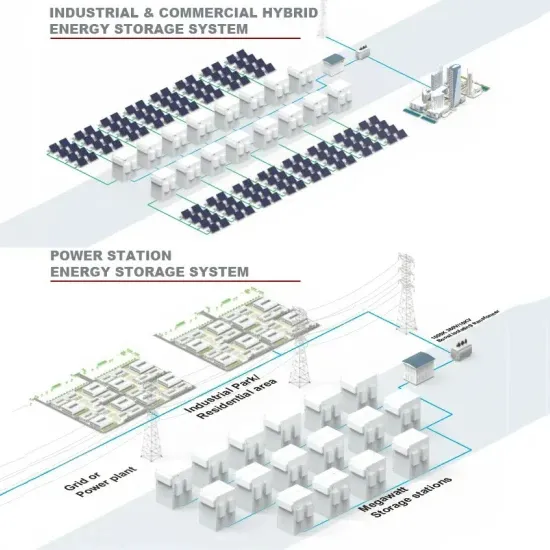

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.