Inverter Power Draw: How Much Power Does an Inverter Use

Mar 17, 2025 · An inverter draws power from a battery depending on its efficiency, typically over 92%. For a connected load of 250 watts, the inverter uses less than 270

Inverter Power Calculator & Formula Online Calculator Ultra

Oct 3, 2024 · Inverters are essential for converting DC (direct current) to AC (alternating current), enabling the use of household appliances, tools, and electronics with batteries or solar power

Inverter Power Draw: How Much Power Does an Inverter Use

Mar 17, 2025 · The actual power draw of an inverter also depends on several factors, such as connected load, inverter type, and usage duration. A larger load will cause the inverter to use

What Size of Inverter is Good for RV? — EASUN POWER

Oct 10, 2024 · What Size of Inverter is Good for RV? The possession of the right inverter ensure you have enough power to run all your essential appliances and gadgets without overloading

How many inverters are needed for a photovoltaic project

How much power does a solar inverter need? he capacity to handle all the power your array produces. As a general rul of thumb,you''ll want to match your solar panel wattage. So if you

How many watts does an off-grid energy storage inverter have

Feb 11, 2024 · Operating at a power range of 1000 to 5000 watts, pure sine wave inverters can efficiently handle larger loads without compromising on quality. Their ability to deliver stable

What Size Inverter Do I Need ?A Complete Guide to

Jun 12, 2025 · Discover how to select the perfect inverter size for your solar or backup power system. Learn to calculate power requirements, account for surge loads, match battery

Inverter Efficiency: Understanding How Much Power You''re

Jul 21, 2025 · Have you ever wondered how much power you''re actually getting from your inverter? Many people think that once they connect their solar panels and batteries to an

Best Outdoor Rated Hybrid Inverter?

Jul 29, 2022 · Tldr; I''m looking for a NEMA3/IP65 or greater rated hybrid inverter, mounted outside to work with the EG4 LiFePower4 batteries. I do not want to backfeed the grid but still

Solar panel inverters & costs: the expert guide

Dec 14, 2023 · Solar panel inverters play a crucial role in any solar panel system, ensuring that the energy harvested from the sun is usable within your home.

Inverter Efficiency: Understanding How Much Power You''re

Jul 21, 2025 · Most modern inverters have efficiency ratings between 90% and 98%. Let''s break it down: If you feed 1000 watts of DC power into your inverter and it outputs 950 watts of AC

How Much Power Does An Inverter Draw With No Load

Aug 4, 2021 · In this article, we''ll help you discover how much power an inverter draws with no load. We''ll further talk about the typical inverter current draws for 12V and 24V inverters before

How Much Space To Leave Between Inverters Solar?

Sep 24, 2024 · When designing a solar power system, it is essential to optimize the distance between solar panels and the inverter to ensure maximum efficiency and output. For indoor or

So, what will a 400 watt power inverter run?

4 days ago · So, what will a 400 watt power inverter run? Wondering what a power inverter can do for you? Well, it''s not that small and you can use in a wide range of indoor and outdoor

How Much Power an Inverter Draws with No Load

To find out how much power an inverter draws without any load, multiply the battery voltage by the inverter no load current draw. A 1000 watt 24V inverter with a 0.4 no load current has a

The ultimate guide to inverter heat pumps: how they

Jul 31, 2024 · Inverter heat pumps are gaining popularity as an energy-efficient and cost-effective solution for heating and cooling homes. Unlike traditional on/off heat pumps, inverter heat

How much power does an Inverter use just sitting there idling?

Oct 30, 2020 · Generally a 3 kW sinewave high freq inverter is 30 to 50 watts of full idle power. A high frequency inverter has two primary stages. First stage is high frequency DC to DC

6 FAQs about [How much power does an outdoor inverter have]

How much power does the inverter use?

While running on battery and no or a small load on the inverter, the "DC Power" reports a power consumption of approx. 23w or 46w more than that the actual power used displayed on the battery shunt on the Venus and in VRM. Display when inverter is loaded with approx 12w (bulb) + 6w of inverter idle consumption:

How to size an inverter?

If you want to know how to size an inverter, the answer is simple. All you have to do is find out how much power your devices need. Then, do some simple math to determine how much more power you need to compensate for inverter losses and headroom.

How much power does a high frequency inverter use?

High frequency MOSFET drive switching is usually the dominate idle consumption but a poorly designed output PWM low pass filter can add to idle losses by having a high reactive power factor load. Generally a 3 kW sinewave high freq inverter is 30 to 50 watts of full idle power. A high frequency inverter has two primary stages.

How much power does a 500W inverter use?

The inverter itself uses about 30W running a 500W load. There are some times that there is no load. Does the inverter still consume the same amount of power then? Or significantly less because it is proportional to the load? It's hard to tell since my usage watt meters are downstream after the inverter. Thanks in advance.

How much power does a 120V inverter use?

All inverters providing ready-to-use 120VAC have an idle consumption. There is a cost to running the circuitry that generates the 120VAC and 60Hz frequency. My 4kW Victron is about 30W as well.

How much power does a 3 kW sinewave inverter use?

There two primary areas effecting idle current. High frequency MOSFET drive switching is usually the dominate idle consumption but a poorly designed output PWM low pass filter can add to idle losses by having a high reactive power factor load. Generally a 3 kW sinewave high freq inverter is 30 to 50 watts of full idle power.

Learn More

- How high is the outdoor power box

- Outdoor Photovoltaic Power Inverter

- How many watts is suitable for a 60V power frequency inverter

- How much is the Spanish outdoor power supply factory

- How many V does it take to charge an outdoor power bank

- How much does BESS outdoor power supply cost in Bolivia

- Do I need to select the power for outdoor inverter

- How much does Seychelles BESS outdoor power supply cost

- How long can the energy storage inverter supply power

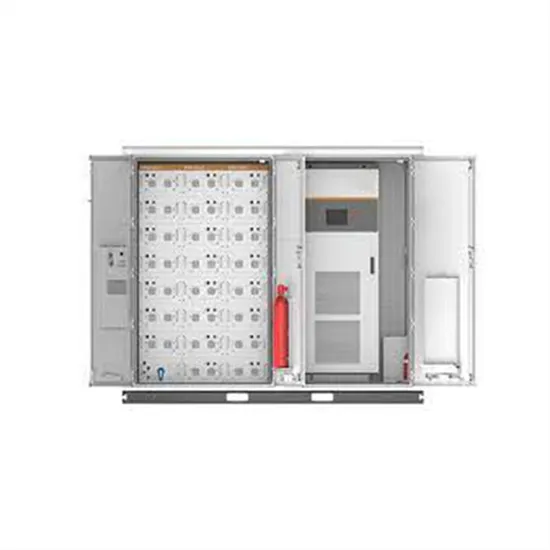

Industrial & Commercial Energy Storage Market Growth

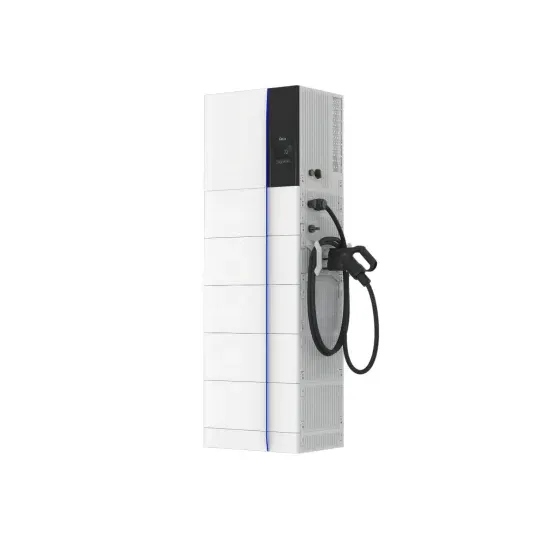

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

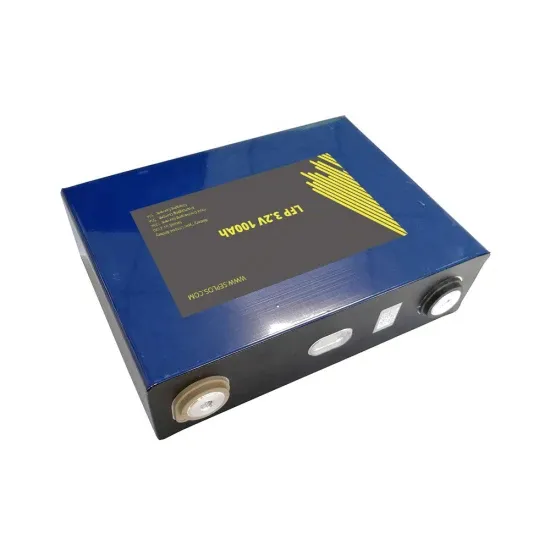

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.