Review of Battery Charger Topologies, Charging Power

Jun 9, 2016 · Abstract—This paper reviews the current status and implemen-tation of battery chargers, charging power levels, and infrastruc-ture for plug-in electric vehicles and hybrids.

Comprehensive DC Power Balance Management in High-Power Three-Level

Feb 2, 2015 · With the increasing popularity of electric vehicles, there is an urgent demand to shorten the charging time, so the development of high-power charging stations with fast

What is a Level 3 Charging Station? A Complete Guide to

Apr 29, 2025 · Installing a Level 3 fast charger at home requires industrial-grade electricity (high voltage, 400V+ three-phase power), which is far beyond typical residential infrastructure.

POWER ELECTRONICS High Voltage Box for Electrified

May 18, 2022 · High Voltage Box for Electrified Vehicles Through a higher mechatronic integration of energy conversion and distribution in the vehicle one can reduce weight and cost, while at

Maximizing power for Level 3 EV charging stations

Apr 1, 2023 · The full-bridge LLC''s high performance (eficiency, power density, etc.) meets the requirements of various combined charging system (CCS) power classes ranging from 300V

Understanding Level 3 EV Charging Stations: The Fastest Way to Power

Jul 28, 2025 · Level 3 EV Charging Stations Deliver Ultra-fast EV Charging With Up to 350 kW Power, Adding Up to 298 Miles of Range Per Hour—Ideal for Highways, Fleets, And Public Use.

Comprehensive DC Power Balance Management in High

Apr 22, 2019 · This paper proposes comprehensive dc power balance man-agement in conjunction with high-power three-level dc–dc con-verter based fast chargers for high-power

A user notices that a mobile device is draining power faster

Sep 11, 2020 · Question: A user notices that a mobile device is draining power faster than is normal. What are three causes of quick battery drain? (Choose three.) The display is set to a

Cutting-Edge Mobile Charging Solutions: Empowering the

Huawei and other tech companies have recently introduced megawatt-level fast charging technologies, primarily targeting electric heavy-duty trucks. These solutions provide extremely

Maximizing power for Level 3 EV charging stations

Apr 1, 2023 · To support the high power levels of fast chargers, the AC-to-DC rectifier is a three phase AC input power factor correction (PFC) stage. Popular topologies for implementing

Supports UFCS integrated fast charging, analysis

May 20, 2024 · There is a ISW SW6308 ACC/ACL three-port multi-protocol buck-boost mobile power supply SOC in the center of the front of the PCB board. It

Designing highly efficient, powerful and fast EV charging

Sep 14, 2023 · The three-phase, three-level reference design as well as the "Bidirectional, dual active bridge reference design for level-3 electric vehicle charging stations" both operate as

Designing highly efficient, powerful and fast EV charging

Sep 14, 2023 · In modern charging stations, one approach to scale the power output to the level required for fast charging is to use modular power converters stacked in parallel. Since the DC

Power Topologies in Electric Vehicle Charging Stations

Apr 1, 2023 · The DC charging station is a Level 3 charger which can cater for very high power level in the range of 120 to 240 kW. The L3 chargers typically charge batteries to 80% State of

A comparison of battery-charger topologies for portable

Apr 2, 2019 · For example, portable power tools, laptops and drones require higher power than fitness devices and wireless headphones. The variety of power levels requires a wide offering

Three-Phase High Power Factor Mains Interface

Aug 17, 2019 · Single-phase Power Factor Corrector (PFC) mains interfaces are commonly employed for low charging power levels (e.g. P < 5 kW), whereas for higher charging power

A Multifunctional Integrated Three-Level Inverter and On-Board Charger

Apr 1, 2025 · This paper presents a highly integrated 4-in-1 power electronics solution for 800V electric vehicle applications, combining on-board charging (OBC), DC boost charging, traction

A New Charging Scheme Based on Mobile Charging Robots Cluster: A Three

Jan 26, 2024 · The rapid development of electric vehicles (EVs) brings great challenges to the charging infrastructure construction and the smooth operation of power systems, which

Preparation of Five-Pages Digest for IEEE IEMDC 2009

Jun 22, 2018 · An off-board charger can be designed for high charging rates and is less constrained by size and weight. Level 1 (convenience), Level 2 (primary), and Level 3 (fast)

High – Efficiency Charging Solution – Level 3 Charging Pile

Discover the high-efficiency Level 3 EV charging pile. Learn about its fast charging, high power output, cost-effectiveness, and installation. Compare with Level 2, explore market trends, and

Matrix Converter-Based Three-Phase Modular High-Power Wireless Charging

Jun 6, 2025 · Due to the increasing requirement of charging power for electric vehicles, especially heavy-duty electric vehicles (HDEVs), this paper proposes novel matrix con

4 FAQs about [Charging high-power mobile three-level power box]

How does a DC charging station work?

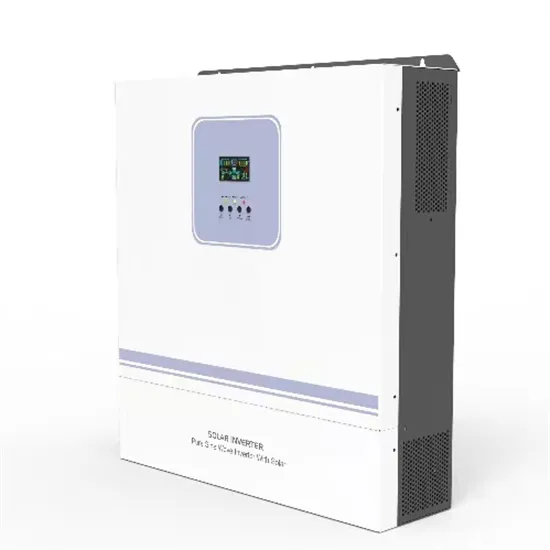

Since the DC charging station will occupy significant volume and space, the power converters must be modular and optimized for high efficiency and high power density. There are two paths to charge the battery pack. The first path is where the grid directly connects to the onboard charger (OBC) housed inside the vehicle.

Why is USB Type-C a good battery charger?

As a result, charging power sources like USB Type-C® have increased their output power capabilities to support faster battery charging for high-capacity batteries. Traditional synchronous buck-based battery chargers cannot take full advantage of high input power because of their maximum efficiency limitations.

Why do portable electronic devices need a high-capacity lithium-ion battery?

Modern portable electronic devices require a high-capacity Lithium-ion battery to power popular features such as high-definition cameras, edge-to-edge high-resolution touchscreens and high-speed data connections.

Why do EVs need fast DC charging?

New EVs have higher ranges and larger battery capacities than their predecessors, necessitating the development of fast DC charging solutions to support quick charging requirements.

Learn More

- Can the three-level power box be used mobile

- Moscow mobile power box manufacturer

- Light storage and charging portable power box

- Power distribution box of mobile power vehicle

- Port Moresby outdoor mobile power box price

- Mobile power box for chemical plant

- Mobile 220v portable power supply lithium battery charging

- 200w mobile power box

- Middle East outdoor mobile power box price

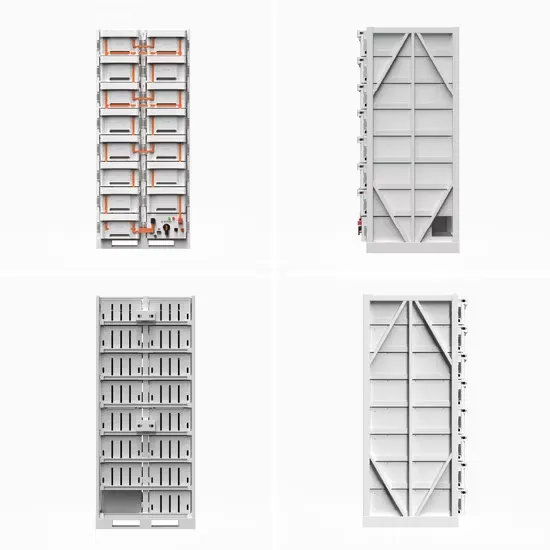

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.