How much does it cost to manufacture a glass bottle

Mold cost is the most important factor in determining how much it costs to manufacture a glass bottle. The mold for a bottle can cost anywhere from $1,500 to $10 million depending on size,

Energy Storage Container Price: Unraveling the Costs and

Oct 1, 2024 · The price of an energy storage container can vary significantly depending on several factors, including its capacity, technology, features, and market conditions. In this article, we

How many energy storage containers are needed for large-scale energy

Jul 1, 2024 · HOW DOES THE COST OF ENERGY STORAGE CONTAINERS INFLUENCE PROJECT PLANNING? Cost considerations around energy storage solutions significantly

Glass Bottles vs Plastic Bottles – Lower Cost

Oct 6, 2020 · Meanwhile, plastic melts at a much lower temperature, at around only 170°C. This means plastic requires significantly less energy to shape and

Energy Storage Container Price: Unraveling the Costs and

Oct 1, 2024 · While the initial cost of energy storage containers can be significant, they offer long-term benefits in terms of energy savings, reliability, and environmental sustainability.

BATTERY ENERGY STORAGE SYSTEM CONTAINER, BESS

Apr 8, 2024 · TLS OFFSHORE CONTAINERS /TLS ENERGY Battery Energy Storage System (BESS) is a containerized solution that is designed to store and manage energy generated

How Much Does Container Energy Storage Cost? A 2025

Nov 20, 2019 · Let''s break down costs like a mechanic disassembling a Tesla battery: Installation & integration (10-15%): Ever tried plugging in a 20-ton power bank? Pro tip: That 100 gigawatt

How much does Shanghai energy storage equipment cost?

May 29, 2024 · Shanghai energy storage equipment costs can vary considerably based on several factors: 1, technology type, 2, capacity, 3, manufacturer, 4, installation requirements.

Energy storage cost – analysis and key factors to

4 days ago · This article provides an analysis of energy storage cost and key factors to consider. It discusses the importance of energy storage costs in the

What Are the 9 Operating Costs of a Plastic Bottle Manufacturing

Jul 24, 2025 · How Much Does It Cost To Operate A Plastic Bottle Manufacturing? The cost structure for operating a plastic bottle manufacturing business, like EcoBottle Innovations,

Why You Should Estimate Costs For A Plastic Bottle Factory

Apr 17, 2025 · How Much Does It Cost To Start Plastic Bottle Manufacturing? Empower your journey into plastic bottle manufacturing by understanding the key startup costs involved. Your

Battery Energy Storage Systems Report

Jan 18, 2025 · This information was prepared as an account of work sponsored by an agency of the U.S. Government. Neither the U.S. Government nor any agency thereof, nor any of their

Hydrogen Storage Cost Analysis

Jul 15, 2025 · DFMA® (Design for Manufacture & Assembly) is a process-based, bottoms-up cost analysis methodology which projects material and manufacturing cost of the complete system

6 FAQs about [How much does it cost to manufacture energy storage containers]

How much does a gas storage system cost?

Generally speaking, the cost of the gas storage tank is the most expensive part of the entire system. Operation and maintenance costs include energy consumption and equipment maintenance. The current cost of compressed air energy storage systems is between US$500-1,000/kWh.

What is energy storage cost?

Energy storage cost is an important parameter that determines the application of energy storage technologies and the scale of industrial development. The full life cycle cost of an energy storage power station can be divided into installation cost and operating cost.

Why is energy storage cost important?

One of the key considerations when it comes to energy storage is cost. Energy storage cost plays a significant role in determining the viability and widespread adoption of renewable energy technologies. The cost of energy storage is a crucial aspect to consider when evaluating the feasibility and scalability of renewable energy systems.

What are the future trends in energy storage costs?

Furthermore, the document discusses future trends in energy storage costs, such as the development of higher capacity cells, cost reductions driven by raw material prices and production capacity, and advancements in system prices and technological progress. Energy storage has become an increasingly important topic in the field of renewable energy.

Why are battery energy storage systems (Bess) costs falling?

A growing industry trend towards larger battery cell sizes and higher energy density containers is contributing significantly to falling battery energy storage system (BESS) costs.

How much does a compressed air energy storage system cost?

The current cost of compressed air energy storage systems is between US$500-1,000/kWh. Supercapacitor energy storage cost: Supercapacitor is a high-power density energy storage device, and its cost is mainly composed of hardware costs, including equipment such as capacitors and control systems.

Learn More

- How much does it cost to manufacture energy storage vehicles in Western Europe

- How much does it cost to customize energy storage containers

- How much does a wind-solar hybrid energy storage cabinet for a communication base station cost

- How much does 500kw energy storage cost

- How much does a Swiss energy storage container cost

- How much does the Turkish energy storage battery cost

- How much does energy storage equipment cost in the Netherlands

- How much does a flywheel energy storage room for a communication base station cost

- How much does energy storage equipment cost in New Zealand

Industrial & Commercial Energy Storage Market Growth

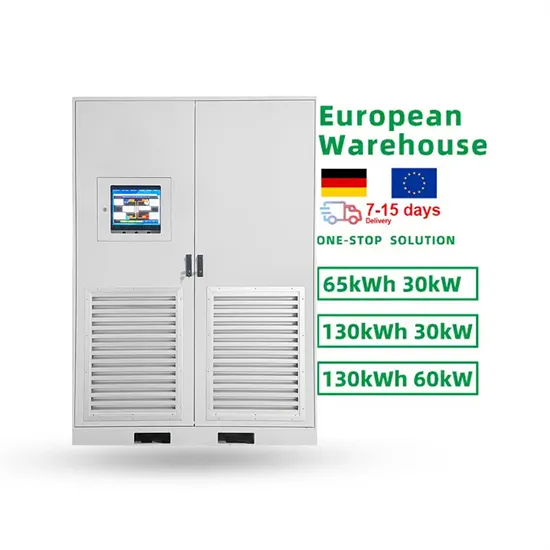

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

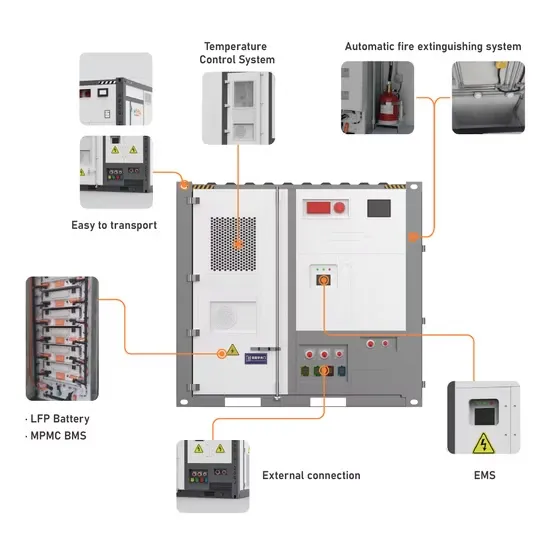

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.