3-phase H-Bridge Inverter | Download Scientific Diagram

Nov 16, 2024 · Download scientific diagram | 3-phase H-Bridge Inverter from publication: Optimal Time-Domain Pulse Width Modulation for Three-Phase Inverters | A novel optimal time

Modeling and simulation of three-phase IGBT full-bridge inverter

Aug 1, 2024 · The field of motor drive makes extensive use of electronic power modeling and simulation of three-phase IGBT full-bridge inverter circuits. The accura

Full Bridge Inverter: Circuit, Waveforms, Working

Jun 2, 2025 · Power inverters are two types according to the characterization that is single-phase inverters and three-phase inverters. Single-phase inverters are

Three-Phase-Full-Bridge-Inverter

May 24, 2025 · Three-Phase Full-Bridge Inverter Simulation Using SPWM Modulation This project simulates a three-phase full-bridge inverter using Sinusoidal Pulse Width Modulation (SPWM).

Experiment: Single-Phase Full-Bridge sinewave Inverter

Nov 7, 2023 · Experiment: Single-Phase Full-Bridge sinewave Inverter Objective The objective of this lab is to analyze the operating performance of the single-phase full-bridge inverter under

Comparison of Inverter Topologies for High-Speed

Nov 18, 2024 · Abstract—This article investigates and compares the perfor-mance of three-phase inverters against sets of single-phase full-bridge inverters in motor drive applications.

Research on Model Predictive Voltage Control Strategy of Three-Phase

Nov 9, 2024 · Model predictive control (MPC) has shown potential for a wide range of applications in the three-phase full-bridge inverters based on its advantages of easy modelling, excellent

MOSFET BASED THREE PHASE BRIDGE INVERTER FOR

Dec 10, 2024 · Recently voltage-fed, current-fed, class-D. Series and parallel resonant inverters are widely used in switching schemes. In this project proposal a modified three phase inverter

IAP200T120 SixPac™ 200A / 1200V 3-Phase Bridge IGBT Inverter

High Power Inverters 5-500 kilowatt Inverters, AC Controllers and IGBT Inverters are available with Full Bridge, Half Bridge, 3-Phase Bridge, Chopper and Soft Start Circuits. Options include

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

Apr 1, 2023 · This application report documents the implementation of the Voltage Fed Full Bridge isolated DC-DC converter followed by the Full-Bridge DC-AC converter using TMS320F28069

Cascaded multilevel converter

Feb 13, 2024 · 1 Overview This demonstration illustrates a three-phase cascaded multi-cell inverter, where each cell submod-ule contains a full bridge. The three individual phase leg

Design and implementation of a novel threeâ phase

Dec 23, 2020 · Abstract: In this study, a new circuit topology of a three-phase half-bridge multilevel inverter (MLI) is proposed. The proposed MLI that consists of a cascaded half-bridge

Two-Stage Single-Source Full-Bridge Based Three

Nov 12, 2020 · Conventional half-bridge based three-phase inverter (HB-TPI) and neutral-point-clamped inverters (NPC) are popular in industry. Nevertheless, they suffer from t

Three Phase Bridge Inverter Explained

Aug 1, 2024 · Using the IGBT module parameter curve of Infineon''s FS400R07A1E3, the three-phase IGBT full bridge inverter circuit simulation during IGBT high-frequency switching is

6 FAQs about [Three-phase inverter full bridge]

What is a three-phase full-bridge inverter?

The three-phase full-bridge inverter topology is the simplest and most widely used structure for systems connected to the grid. It consists of three sets of "bridges", each of which consists in two switches and their corresponding reverse-parallel diodes.

What is a three phase bridge inverter?

A three phase bridge inverter is a device which converts DC power input into three phase AC output. Like single phase inverter, it draws DC supply from a battery or more commonly from a rectifier. A basic three phase inverter is a six step bridge inverter. It uses a minimum of 6 thyristors.

What are the disadvantages of a three-phase full-bridge inverter?

One of the disadvantages of the three-phase full-bridge inverter is the number of components, since a total of 12 switches and 12 diodes are required. The problem with this number of components is cost and reduced reliability. As an alternative we have the three-phase bridge inverter.

How does a 3 phase inverter work?

However, most 3-phase loads are connected in wye or delta, placing constraints on the instantaneous voltages that can be applied to each branch of the load. For the wye connection, all the “negative” terminals of the inverter outputs are tied together, and for the detla connection, the inverter output terminals are cascaded in a ring.

How many switches are needed for a 3-phase bridge inverter?

In particular, considering “full-bridge” structures, half of the devices become redundant, and we can realize a 3-phase bridge inverter using only six switches (three half-bridge legs). The 3-phase bridge comprises 3 half-bridge legs (one for each phase; a, b, c).

How to solve a three-phase IGBT full bridge inverter circuit?

Based on the IGBT behavior model and utilizing the characteristics of FPGA multi channel time domain parallel computing, a steady-state and transient two-stage method is used to simulate, model and solve the three-phase IGBT full bridge inverter circuit.

Learn More

- Three-phase inverter full bridge

- Three-phase bridge inverter MOSFET

- Three-phase inverter construction in Casablanca Morocco

- North Asia three-phase inverter manufacturer

- Inverter three-phase energy storage

- High power three-phase pwm inverter

- What is a three-phase grid-connected inverter

- Three-phase water pump inverter manufacturer

- Huawei inverter three-phase range

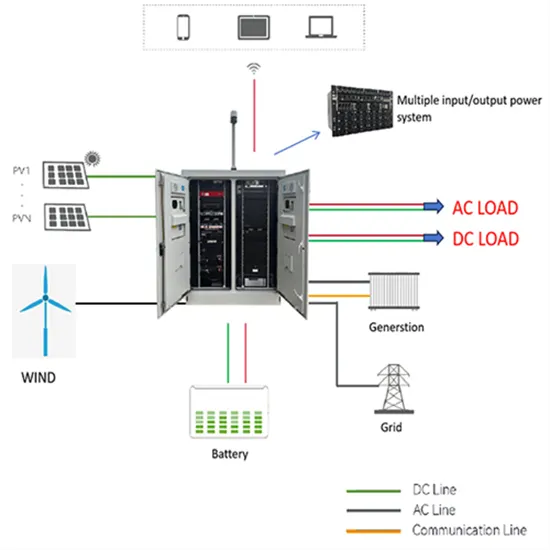

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.