Understanding the Voltage – Current (I-V) Curve

Feb 21, 2025 · The operating point of a PV module is the defined as the particular voltage and current, at which the PV module operates at any given point in

Chapter Number 3.0 Solar PV modules Explained in detail

Mar 29, 2023 · Since single solar cell provides smaller voltage, it is required to connect many solar cells in series to get higher PV module voltage to charge a battery. As mentioned earlier,

MODELING OF SOLAR PHOTOVOLTAIC MAXIMUM

Aug 17, 2024 · Running the PV module at its maximal power point will maximize power delivery to the batteries and enhance efficiency [4]. Additionally, a longer battery life requires the battery

Photovoltaic (PV) Cell: Working & Characteristics

1 day ago · The article provides an overview of photovoltaic (PV) cell, explaining their working principles, types, materials, and applications. It also outlines the

Modeling of Photovoltaic MPPT Lead Acid Battery Charge

Jan 1, 2020 · The maximum power of the photovoltaic panel is tracked by the Perturb and Observe MPPT algorithm. The battery charge controller charges the lead-acid battery using a

Series, Parallel & Series-Parallel Connection of

3 days ago · To achieve such a large power, we need to connect N-number of modules in series and parallel. A String of PV Modules When N-number of PV

The Role of Constant Voltage MPPT in Modern Renewable

2 days ago · Constant voltage MPPT regulates the PV module voltage to a constant reference value, typically close to the battery voltage. By doing so, it ensures that the PV array operates

Maximizing energy transfer of solar-battery charge

Sep 1, 2024 · This systematic approach requires specifying the DC load voltage, configuring the battery bank, and selecting PV modules with compatible Vmp (voltage at maximum power)

Protection of Photovoltaic Panels: Essential Safeguards for

Adequate protection of photovoltaic panels, tailored to their characteristics, is a key factor ensuring their long-term and safe operation under environmental conditions. Properly selected

Constant Voltage Battery Charger Energized from an

Aug 1, 2022 · The photovoltaic system designed and simulated enables maximizing the efficiency of a photovoltaic panel to charge LiPo batteries with constant voltage, it comprises a fast

Modeling and Control of a Standalone Photovoltaic System

Jun 13, 2021 · independent control loops are used to control the whole standalone system. Those are MPPT control loop for extracting maximum power from PV module, battery control loop for

Constant Voltage Battery Charger Energized from an MPPT Photovoltaic

Aug 2, 2022 · The photovoltaic system designed and simulated enables maximizing the efficiency of a photovoltaic panel to charge LiPo batteries with constant voltage, it comprises a fast

Design and Analysis of Standalone Solar PV system with

Dec 25, 2024 · Abstract— This paper presents the circuit modelling of a solar power system integrating maximum power point tracking (MPPT) and a battery energy storage system. The

Modelling and Simulation of Solar PV-Powered

Sep 16, 2023 · The three steps of battery charging used for lead acid battery are floating charging, constant voltage charging, and peak power tracking charging.

Photovoltaic Basics (Part 2): Integrating the

Sep 30, 2024 · To effectively harness solar energy, it''s essential to understand how to properly configure the components of a system. This article focuses on

MODELING OF SOLAR PHOTOVOLTAIC MAXIMUM

Aug 17, 2024 · Optimizing power distribution to the batteries and improving efficiency can be achieved by operating the PV module at its maximum power point [6,7]. To charge the

Batteries in Photovoltaic Systems – Applications

4 days ago · Batteries: Fundamentals, Applications and Maintenance in Solar PV (Photovoltaic) Systems In a standalone photovoltaic system battery as an

Design and Control of Solar Powered Boost Converter

A DC converter is equivalent to an AC transformer with a continuously variable turn‟s ratio. Boost converters are used to obtain higher output voltage in comparison with the input DC voltage

How Constant Voltage MPPT Improves Solar Power Efficiency

Aug 16, 2025 · Constant Voltage MPPT offers significant advantages in terms of improved efficiency, reliability, and cost-effectiveness compared to conventional VV-MPPT systems. Its

Stand-Alone Solar PV AC Power System with Battery Backup

Jul 22, 2020 · The proposed V system design with integrated battery storage system for a small household with a power consumption demand of 1,419.6 kw/H per month: (a) photovoltaic

Fig 1. Current-Voltage characteristics (I-V) curve of a PV module

Figure 1 dictates the current-voltage (I-V) characteristics curve and also the power-voltage (PV) characteristics curve of a PV module for a particular solar irradiance and temperature condition.

Module-level direct coupling in PV-battery power unit under

Jan 1, 2023 · In this work, we experimentally examine the function of a laboratory scale unit of a 7-cell silicon heterojunction PV module directly connected to a lithium-ion battery and variable

Modeling of Photovoltaic MPPT Lead Acid Battery

The maximum power of the photovoltaic panel is tracked by the Perturb and Observe MPPT algorithm. The battery charge controller charges the lead-acid battery using a three-stage

Photovoltaic Module: Definition, Importance, Uses and Types

Jul 5, 2024 · Photovoltaic Module (PV) Definition, Uses, Types including Portable PV, Rooftop PV, and Hybrid PV. Advantages and Disadvantages of Photovoltaic Modules.

Solar Photovoltaic and Battery Energy Storage System

Jul 22, 2020 · The proposed V system design with integrated battery storage system for a small household with a power consumption demand of 1,419.6 kw/H per month: (a) photovoltaic

Voltage, Current, and Temperature Monitoring for Solar

Dec 14, 2016 · Description This verified reference design provides an overview on how to implement a solar module level monitoring and communication subsystem. This TI Design

Buck Charger with MPPT and Boost Converter for Solar

Apr 1, 2023 · A controller is used between the solar panel and the load to make the output voltage constant to realize simple MPPT function. It is suitable for applications with stable external

6 FAQs about [Photovoltaic panel battery constant voltage module]

What is a solar PV MPPT charge controller?

A Solar PV MPPT charge controller includes an MPPT tracker and a battery charge controller. The MPPT tracks the maximum power from the PV panel and delivers it to the battery charge controller.

What is a solar PV charge controller?

The solar PV charge controller is widely used in standalone system applications including street lighting , telecommunication base station, rural electrification , etc. A Solar PV MPPT charge controller includes an MPPT tracker and a battery charge controller.

How do solar PV and battery storage work?

Both solar PV and battery storage support stand-alone loads. The load is connected across the constant voltage single-phase AC supply. A solar PV system operates in both maximum power point tracking (MPPT) and de-rated voltage control modes. The battery management system (BMS) uses bidirectional DC-DC converters.

How does a PV battery charge controller work?

The MPPT tracks the maximum power from the PV panel and delivers it to the battery charge controller. The charge controller charges the battery through a multi-stage charging strategy to effectively charge the battery without damaging the battery caused by excessive charge gassing and overheat.

How to control a solar PV plant if the battery is not fully charged?

Set the variant variable MPPT to 0 to choose the perturbation and observation MPPT. Set the variable MPPT to 1 to choose incremental conductance. This example uses a boost DC-DC converter to control the solar PV power. When the battery is not fully charged, the solar PV plant operates in maximum power point.

What is buck topology in solar PV charge controller?

Since the PV array voltage is higher than the battery voltage, a buck topology is commonly chosen for solar PV charge controller application [14-16]. The buck converter operates as a regulator to step down the input voltage from the PV array while maintaining its power delivery to charge the battery.

Learn More

- Kigali Standard Photovoltaic Module Panel

- Photovoltaic panel voltage and area

- Photovoltaic panel 700w voltage

- Can a 22v photovoltaic panel charge a 12v battery

- How much voltage does a 100 watt photovoltaic panel have

- How big a battery should a 400w photovoltaic panel be equipped with

- Which brand of photovoltaic panel battery is good

- 200w photovoltaic panel charging 48v battery

- Monitoring battery photovoltaic panel installation

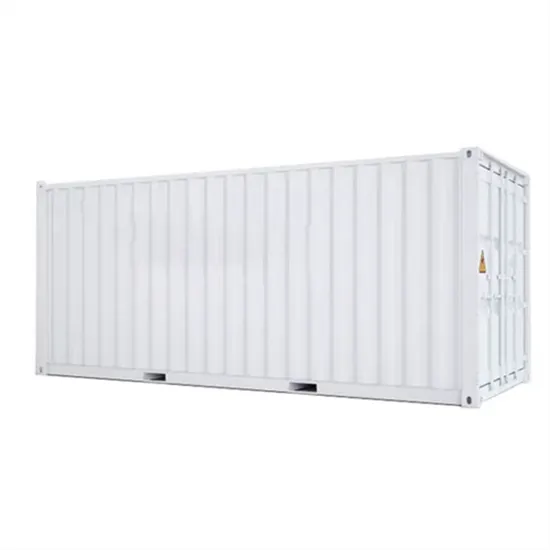

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.