Tempered glass for photovoltaic panels

Dec 27, 2020 · Are solar panels made of tempered glass? h is sometimes called toughened glass. There are specific properties that make tempered glass suitable for the manufacturing of solar

What kind of glass is used for solar panels?

Sep 29, 2024 · The glass used for solar panels is known as tempered glass. This type of glass is made by heating regular glass to a very high temperature and then rapidly cooling it. This

List of Solar Materials Used to Produce Solar Panels

Dec 12, 2024 · 3. Tempered Glass Solar panels are composed of tempered glass—especially low-iron tempered glass. It lets most light pass through and shields the solar cells underneath.

What kind of glass are solar panels made of? | NenPower

Sep 11, 2024 · The type of glass used in solar panels is 1. low iron tempered glass, 2. high transparency, 3. durability, and 4. anti-reflective coatings. Low iron tempered glass is essential

Solar Glass: applications and comparison to Light-Trapping

Apr 17, 2025 · At the core of every solar panel are photovoltaic (PV) cells. These are the parts that convert sunlight into usable electricity. But PV cells are fragile and need strong protection

Glass in Solar Panels: The Clear Key to Clean Energy

Apr 17, 2025 · Surprisingly, glass plays a huge role in how solar panels work—not just by covering them, but by helping them last longer, perform better, and generate more clean energy.

Photovoltaic glass: the perfect fusion between

Aug 18, 2025 · Photovoltaic glass is transparent solar panels designed to replace conventional glass in buildings and structures. These panels are capable of

Thickness of tempered glass in photovoltaic panels

What is a thin film solar panel? They are made of standard,non-tempered glass and can be as thin as 2.5 mm. Thin-film solar panels are lightweightbecause the glass encloses the panel

Enhance Your Solar Panels with Tempered Glass: Durable,

Tempered glass for solar panels is a specialized type of safety glass designed with the primary function of protecting solar photovoltaic (PV) cells from environmental damage. Its key

6 FAQs about [Are photovoltaic panels made of tempered glass ]

Are solar panels made of tempered glass?

Solar panels are made of tempered glass, which is sometimes called toughened glass. There are specific properties that make tempered glass suitable for the manufacturing of solar panels. First of all tempered glass is much stronger than other types of glass. Secondly, tempered glass is considered safety glass.

What type of glass is used in solar panels?

The type of solar glass directly influences the amount of solar radiation that is being transmitted. To ensure high solar energy transmittance, glass with low iron oxide is typically used in solar panel manufacturing. Solar panels are made of tempered glass, which is sometimes called toughened glass.

Can tempered glass be used for solar panels?

There are specific properties that make tempered glass suitable for the manufacturing of solar panels. First of all tempered glass is much stronger than other types of glass. Secondly, tempered glass is considered safety glass. In case it breaks, it will shatter in thousands of small pieces, that won't be harmful.

What is Photovoltaic Glass?

At present, the mainstream product of photovoltaic glass is low-iron tempered patterned glass (also known as tempered suede glass) with a thickness of 3.2mm or 4mm.

Why is tempered glass better than plate glass for solar panels?

Intense thunderstorms, tornadoes, hurricanes, tropical storms and hail storms can all put your rooftop panels at risk of damage, so a higher degree of durability is an essential factor when producing PV panels. As mentioned above, tempered glass is the superior option over plate glass for solar modules.

Why should solar panels be made of glass?

When manufacturing solar panels glass is seen as a key component for its durability, transparency, stable nature, variability and ability to further an eco-friendly agenda of recycling. Due to the nature of all of these added benefits, it is no wonder that many high rated solar panel manufacturers choose glass.

Learn More

- Australia double glass photovoltaic panels wholesale

- Tempered glass laminated photovoltaic

- 2mm photovoltaic tempered glass

- Somaliland glass photovoltaic module panels

- Do photovoltaic panels have glass

- Glass photovoltaic panels for power generation

- Transparent glass curtain wall photovoltaic panels

- Differences between glass panels and photovoltaic panels

- Can photovoltaic panels still generate electricity through glass

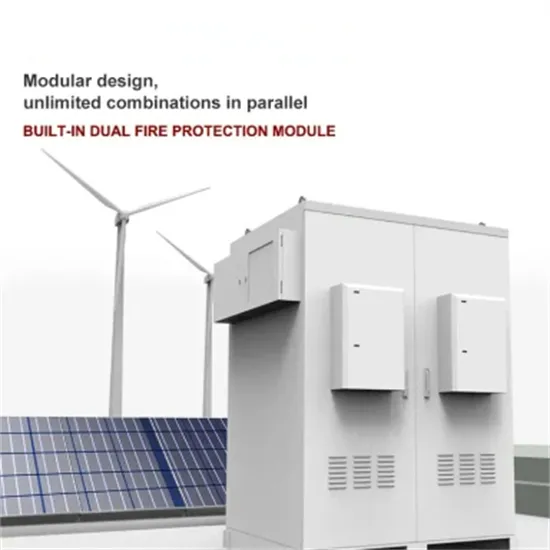

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.