Lithium Battery Charging Cabinet: The Essential Guide to

May 9, 2025 · The widespread use of lithium-ion batteries across various industries and applications—ranging from power tools to electric vehicles—has led to increasing concern

Industrial Battery Installation Fundamentals | Ethos Power

Before installing industrial batteries, proper site preparation is essential: Industrial battery installation requires strict safety protocols: 1. Transportation and Handling. 2. Arrangement

How to correctly install lithium battery energy

Mar 25, 2024 · In this guide, we will introduce the correct installation steps after receiving the lithium battery energy storage cabinet, and give the key steps

What Are Battery Rack Cabinets and Why Are They Essential?

Jun 15, 2025 · Battery rack cabinets are modular enclosures designed to securely house and organize multiple batteries in industrial, telecom, or renewable energy systems. They optimize

Standard Specifications for Lithium Battery Energy

AZE''''s 27U indoor battery rack cabinets painted with polyester powder, suitable for different brands lithium-ion batteries, it is the perfect solution for housing your Low Voltage Energy

How to Pair and Charge Energy Storage Batteries: A Practical

Mar 26, 2021 · In the world of energy storage systems, proper battery pairing and charging isn''t just technical jargon; it''s the difference between a smooth power flow and what I call "electrical

Battery Charging Cabinet Solutions for Safer Lithium-Ion Battery

May 23, 2025 · A battery charging cabinet is a purpose-built unit designed to store and charge batteries safely, particularly lithium-ion types. These cabinets often include built-in fire-resistant

Safe Storage of Lithium-Ion Battery: Energy Storage Cabinet

Oct 16, 2023 · Why Choose AlphaESS Energy Storage Cabinet When it comes to ensuring the safe storage of lithium-ion batteries, AlphaESS Energy Storage Cabinets stand out as a top

Tips for Designing Battery Cabinets/Enclosures | SBS Battery

Jan 16, 2025 · There may be multiple ways to configure the cabinet, so consider all possible options. For instance, if a battery, rack and charger are required the system can be designed

UNDERSTANDING UPS SYSTEMS AND BATTERIES

Jul 17, 2024 · Additional cooling is rarely required for a battery cabinet, but the cabinet must have (1) unobstructed paths within the cabinet for hot air to rise, and (2) adequate openings for hot

How to Install and Set Up a Battery Storage Cabinet at Home

Apr 19, 2025 · Batteries, the core of the cabinet, store energy in forms such as lithium-ion or lead-acid, noted for their high energy density and cycle life. Chargers ensure that batteries are

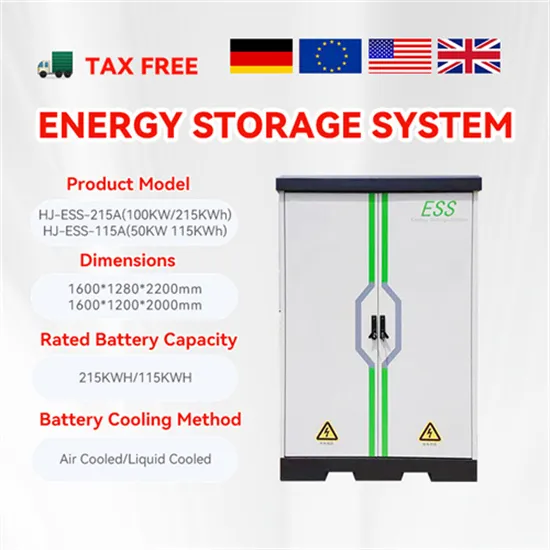

ESS-GRID Cabinet Brochure EN-250401

Jul 15, 2025 · The ESS-GRID Cabinet series are outdoor battery cabinets for small-scale commercial and industrial energy storage, with four diferent capacity options based on diferent

How does the energy storage cabinet charge? | NenPower

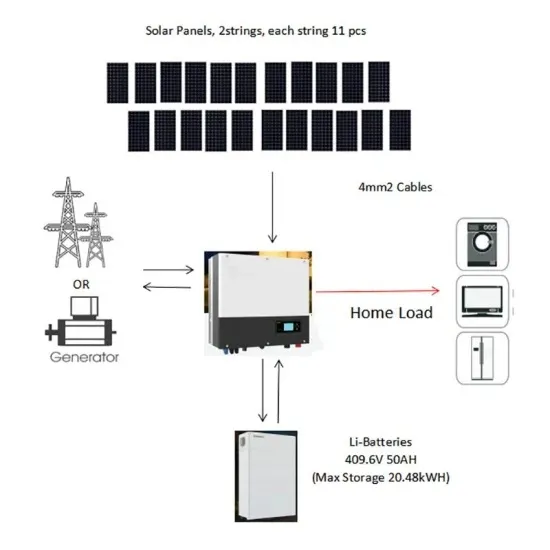

Mar 4, 2024 · 1. Energy storage cabinets use a variety of mechanisms for charging,2. The primary method involves the integration of renewable energy sources,3. The systems often employ

6 FAQs about [How to charge for the energy battery cabinet and battery cabinet at the site]

How to choose a battery charging cabinet?

Opt for a fireproof battery charging cabinet with thermal insulation and fire-resistant materials to enhance safety. Ensure that the battery storage cabinets meet national and international safety standards for handling hazardous materials.

What is a battery charging cabinet?

A battery charging cabinet provides a safe and efficient solution for managing these risks by offering controlled environments for both charging and storage. A lithium battery cabinet is designed to protect batteries from overheating, prevent thermal runaway, and contain any potential fires.

What type of batteries are used in energy storage cabinets?

Lithium batteries have become the most commonly used battery type in modern energy storage cabinets due to their high energy density, long life, low self-discharge rate and fast charge and discharge speed.

Do you need a lithium ion battery storage cabinet?

Organizations handling lithium-ion batteries must adhere to strict safety standards. Using lithium battery storage cabinets ensures compliance with fire safety and hazardous material regulations. A lithium ion battery cabinet provides a dedicated, secure storage space, reducing the chances of battery loss, theft, or improper handling.

What is energy storage cabinet?

Energy Storage Cabinet is a vital part of modern energy management system, especially when storing and dispatching energy between renewable energy (such as solar energy and wind energy) and power grid. As the global demand for clean energy increases, the design and optimization of energy storage sys

What makes a good battery storage cabinet?

An effective battery storage cabinet includes a dual-fan system to maintain optimal temperatures by drawing in cool air and expelling heat. This helps prevent thermal runaway and extends battery lifespan. A lithium battery storage case with an in-built sump collects any leaked electrolyte, reducing the risk of short circuits and chemical damage.

Learn More

- How much does a site energy battery cabinet cost

- How to charge the battery cabinet liquid cooling energy storage solar panels

- Cote d Ivoire site energy battery cabinet franchise

- Is there a site energy battery cabinet in Bucharest

- How long can the lithium iron phosphate battery of the energy storage cabinet be used

- How long does it take for the lithium iron phosphate battery station cabinet to charge the base station

- How much does a new energy battery cabinet cost per kilowatt-hour

- How to connect the energy of new energy battery cabinet

- How long is the shelf life of the battery in the energy storage cabinet

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.