Designing a BESS Container: A Comprehensive Guide to Battery Energy

Apr 10, 2023 · The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system.

Energy storage container ventilation system

Energy storage container ventilation system What is a battery energy storage system (BESS) container? This includes features such as fire suppression systems and weatherproofing,

A thermal management system for an energy storage battery container

May 1, 2023 · The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper innovatively proposes

Energy storage container ventilation calculation

To ensure a suitable operating environment for energy storage systems,a suitable thermal management systemis particularly important. If you''''re looking to combat excessive moisture

Ventilation Requirements for Energy Storage Containers

Summary: Proper ventilation design is critical for energy storage containers to prevent thermal runaway, ensure system longevity, and meet international safety standards.

Upgrading the Ventilation System of the New Energy Storage

Jan 28, 2024 · From the perspective of safety performance, the application of the JIECNAG industrial linear actuator provides a more reliable ventilation solution for energy storage

Energy storage container ventilation calculation

If you''''re looking to combat excessive moisture inside your 10 foot Storage Container, 20 foot Storage Container, 40 foot container or 40? high cube container, we offer Louvered vents,

This space should be left blank, except for the name of

Dec 16, 2024 · A key finding in the study is the need for exhaust ventilation of explosive gasses. The ventilation rates should be set based on the BESS''s storage capacity and the room size.

Ventilation for Shipping Containers: Guide to

4 days ago · Discover the importance of ventilation for shipping containers, learn how to install vents, and explore various venting options for optimal air

Ventilation Volume Standards for Energy Storage Containers

Summary: Proper ventilation design is critical for energy storage systems. This guide explores global ventilation volume standards, calculation methods, and best practices to prevent

DESIGNING AN HVAC SYSTEM FOR A BESS CONTAINER:

Jun 8, 2023 · The Battery Energy Storage System (BESS) is a versatile technology, crucial for managing power generation and consumption in a variety of applications. Within these

Explosion Control Guidance for Battery Energy Storage

4 days ago · EXECUTIVE SUMMARY Lithium-ion battery (LIB) energy storage systems (BESS) are integral to grid support, renewable energy integration, and backup power. However, they

Thermal Runaway Gas Sensing and Fire Suppression / Ventilation

Thermal safety management of lithium-ion battery energy storage systems for use in ocean-going and subsea applications: V. Somandepalli and K. Marr, " Thermal safety management of

FIRE AND EXPLOSION PROTECTION FOR BESS

Jan 9, 2024 · The NFPA 855 standard, which is the standard for the Installation of Stationary Energy Storage System provides the minimum requirements for mitigating the hazards

Ventilation Volume Calculation for Energy Storage Containers

Summary: Proper ventilation design is critical for ensuring the safety and efficiency of energy storage systems. This guide explains how to calculate ventilation requirements for battery

What is Ventilated Container – A Complete in

Aug 18, 2025 · Here are some key differences: Specific openings or perforations, common only to ventilated containers, facilitate controlled airflow and proper

Designing BESS Explosion Prevention Systems Using CFD

NFPA 855/69 Requirements for Lithium-Ion BESS Explosion Control To address the safety issues associated with lithium-ion energy storage, NFPA 855 and several other fire codes require any

6 FAQs about [Ventilator for energy storage container]

Can a battery container fan improve air ventilation?

The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper innovatively proposes an optimized system for the development of a healthy air ventilation by changing the working direction of the battery container fan to solve the above problems.

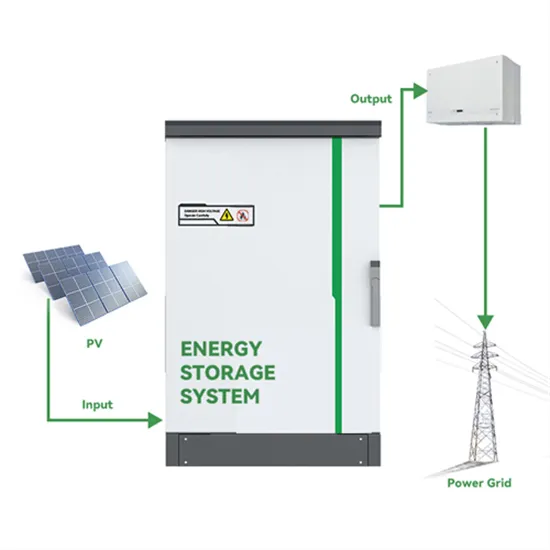

What is a battery energy storage system?

The Battery Energy Storage System (BESS) is a versatile technology, crucial for managing power generation and consumption in a variety of applications. Within these systems, one key element that ensures their efficient and safe operation is the Heating, Ventilation, and Air Conditioning (HVAC) system.

How does a battery room ventilation system work?

The battery room has a separate ventilation system, see Figure 7, Figure 8, and Figure 9. During normal operation, ventilation fans draw air from the ventilated parking garage to ensure sufficient air exchange in the battery compartment for cooling purpose. The fans are equipped with fire dampers connected to the fire alarm system.

What is the best hydrogen gas ventilation system?

Best for: Small battery rooms, telecom enclosures, and backup power storage areas. The VS-24 Hydrogen Gas Ventilation System is designed for large battery storage areas and industrial applications where high-volume hydrogen gas removal is required. Best for: Large battery rooms, UPS power systems, industrial storage areas, and utility substations.

Why do you need a ventilation system?

Designed for safety, reliability, and compliance, our ventilation solutions protect your facilities from dangerous gas buildup while maintaining optimal environmental conditions. Battery rooms and critical facilities often produce hazardous gases, such as hydrogen, which can accumulate to unsafe levels. Eagle Eye’s Ventilation Systems provide:

What is energy storage system (ESS)?

The energy storage system (ESS) studied in this paper is a 1200 mm × 1780 mm × 950 mm container, which consists of 14 battery packs connected in series and arranged in two columns in the inner part of the battery container, as shown in Fig. 1. Fig. 1. Energy storage system layout.

Learn More

- Mali integrated energy storage container 5g base station

- Belize Energy Storage Container House Design

- Suriname Energy Storage Container Overseas

- What is the capacity of the container energy storage cabinet

- Thimphu EK container energy storage system

- Monrovia Container Energy Storage Project

- What kind of battery is the energy storage container battery

- Israel container energy storage fire exhaust fan wholesale

- Uruguay Energy Storage Container Procurement Announcement

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.