Inverter pre-charge resistor size?

May 20, 2022 · Unfortunately, :cry: I ordered a 20 ohm 100w resistor before discovering the invaluable guid in resources about how to design a pre-charge inverter switch by the wonderful

Renogy 3000w Pure Sine Wave Inverter Charger 12V DC to 120V AC

Renogy 3000w Pure Sine Wave Inverter Charger 12V DC to 120V AC Surge 9000w for Off-Grid Solar RV Boat Home w/LCD Display, Auto Transfer Switch, Compatible with Lithium Battery

预充电电路原理及作用

Jul 26, 2021 · 仿真结果与理论计算完全一致。 实际选型原则: 由以上理论分析及仿真验算可得出结论,根据输入参数,预充电阻选型标准如下: 电阻R ≤

Sensata Precharge Circuit for Hybrid and Electric Vehicules

Dec 17, 2020 · precharge circuit is used to limit this inrush current to slowly charge the downstream capacitance. It plays a critical role in the proper operation and protection of

Charging Battery While Connected To Inverter

Mar 3, 2023 · Can I charge a battery while it''s connected to an inverter? in short, the answer is Yes, you can charge a battery while using an inverter. but make

Voltage Source Inverter with Pre-Charge

Feb 13, 2024 · This demonstration shows a closed-loop controlled 3-phase voltage source inverter with a DC-link pre-charge. A stiff three-phase voltage source with line inductance is

PLECS应用范例(85):带预充电的电压源逆变

Oct 24, 2023 · 本演示展示了一种具有直流链路预充电的闭环控制 三相电压源逆变器。 在2电平IGBT变换器的交流侧连接一个带线电感的刚性三相电压源。 该

Understanding How an Inverter Charger Charges

Jul 4, 2023 · It regulates the voltage and frequency of the AC power, ensuring compatibility with standard electrical devices and appliances. B. Charger The

Why Pre-Charge Circuits are Necessary in High-Voltage

Dec 23, 2023 · High-voltage systems (100V+) often use precharged circuits to limit inrush current. This process protects the system from damage, extends lifespan, and increases reliability.

An Improved AC-Precharging Strategy for the Startup

Nov 11, 2024 · An Improved AC-Precharging Strategy for the Startup Process of Modular Multilevel Converters Based on Time-Domain Analysis Published in: 2024 CPSS & IEEE

Inverter capacitor precharge procedure

Oct 23, 2022 · Seems the LiFePO4 Rack batts have a built-in resistor circuit to do the pre-charge, but a common mistake is to turn on the battery, then flip the breaker you installed in-line to the

Precharge Circuits, How to Protect High Voltage

Jun 30, 2022 · High voltage pre-charge control circuits, a must-have design to protect electrical power system in electric vehicles. It consists of precharge

Precharge with AC input?

Jun 8, 2022 · It works, but you need to keep the AC IN powered on and you need to wait about one minute, depending on inverter type and setup. Some models take longer to "charge" their

Quattro Precharge options

Aug 23, 2023 · I have a bank of 8 100AH batteries hooked up to a 5KVA Quattro unit. When I first close the breaker connecting the Quattro to the batteries, they will go into short circuit alarm

6 FAQs about [AC inverter pre-charging]

How to charge a DC inverter?

Pre-charging an inverter is simple. You just need to connect a suitable resistor between the DC load and inverter for a few seconds. Then, remove the resistor and connect the DC load to the inverter. The following method breaks this down, step by step. Connect the inverter to your negative and positive busbars.

Do I need to pre-charge my inverter?

All of our large inverter and inverter/charger kits include the required resistor to allow you to safely pre-charge it. If you have a lithium battery bank, it’s really important to pre-charge your inverter (2000W+) to protect your BMS. Nevertheless, pre-charging is still necessary if you have AGM batteries.

Can a grid-tie inverter be pre-charged from the AC side?

This application note presents a technique for pre-charging the DC bus of a grid-tie inverter from the AC side. This technique is commonly used in imperix systems. Proper solutions for discharging the power converter is also addressed. Why pre-charging an inverter’s DC-bus?

How does a pre-charge circuit protect the inverter?

Pre-charge circuits protect the inverters by controlling the initial power surge. PTC thermistors can help a pre-charge circuit protect the inverter. Inrush current occurs when the maximum instantaneous input current flows through a system when the electrical power is switched on.

Why do inverters pre-charge a DC-BUS?

Why pre-charging an inverter’s DC-bus? Nowadays, Voltage Source Converter (VSCs) are widely used in grid-tied applications. They indeed offer several benefits over Current Source Converters (CSCs), such as reduced filtering requirements, superior efficiency and easier use in weak grid conditions.

How do I use an AC pre-charge circuit?

One way of implementing that AC pre-charge circuit is by using imperix’s handy Grid connection panel. It includes the three current-limiting resistors and the two relays (controllable from a B-Box controller), as well as an additional circuit breaker. When the converter is not switching and that its DC bus is not charged, all contactors are open.

Learn More

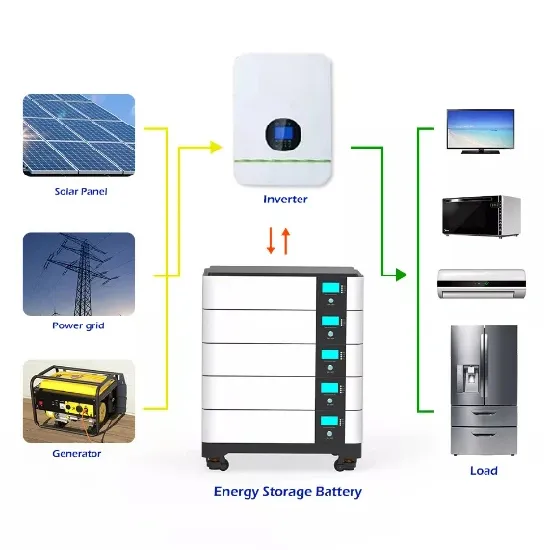

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.