Photovoltaic inverter aluminum wire connection method

Can string inverter solar panels be wired together? As discussed above,string inverter solar panel arrays can be wired together in series or parallel-- or a hybrid of both. All PV modules that

PV Inverter Aluminum Casing Solutions | High-Precision Die

Optimize your PV inverter performance with durable, custom aluminum casings from a trusted ISO 9001-certified manufacturer. Enhanced thermal management & energy efficiency. Get a

Aluminum Die-Casting for Photovoltaic Inverter Parts:

Jun 1, 2023 · Aluminum die-casting is a popular manufacturing process for producing high-quality and cost-effective photovoltaic inverter parts. In this process, molten alum...

Mingtai Aluminum''s 3004-O aluminum sheet for photovoltaic inverters

Traditional photovoltaic inverters use 1060, 1070, and 5052 (O-state) aluminum for the outer casing. Mingtai Aluminum''s new product, a 3004 aluminum plate, has good formability,

ALUMINUM EXTRUSIONS FOR PHOTOVOLTAICS AN

Photovoltaic inverter aluminum wire connection method To connect single strands of small cross-section copper and aluminum wires, a tin-plate on the copper wires should be done and then it

Photovoltaic inverter aluminum shell model list

Apr 7, 2024 · Photovoltaic inverter aluminum shell model list What is a solar PV inverter Buyer''s Guide? The Solar Builder''s Solar PV Inverter Buyer''s Guide is a resource that allows checking

Photovoltaic inverter aluminum die casting

Nov 20, 2022 · Whether single-phase or three-phase PV inverters, PrimeVOLT''''s products were all designed with uni-body aluminum die-casting housing which, in contrast with conventional

Aluminium Alloys in Solar Power − Benefits and

Aug 16, 2013 · To sum up, aluminium plays an important role in various kinds of solar power systems in‐ clude concentrating solar power (CSP), photovoltaic

Manufacturing Sales Photovoltaic Inverter Aluminum Die

Moreover, aluminum is a readily available and affordable material, making it a cost-effective choice for producing photovoltaic inverter Photovoltaic Inverter Aluminum Die Casting Parts

What aluminum alloy can be used for photovoltaic inverter

Aug 24, 2023 · Aluminum alloys used for photovoltaic (PV) inverters need to balance various properties such as thermal conductivity, electrical conductivity, corrosion resistance, strength,

Photovoltaic inverter aluminum die casting

Nov 20, 2022 · About Photovoltaic inverter aluminum die casting As the photovoltaic (PV) industry continues to evolve, advancements in Photovoltaic inverter aluminum die casting have

Manufacturing Photovoltaic Inverter Aluminum Die Casting

Photovoltaic inverter aluminum die casting parts have emerged as key components in the solar energy industry, driving advancements in efficiency, reliability, and sustainability. These parts,

Material flows and embodied carbon emissions of aluminum

Apr 1, 2025 · Aluminum is widely used in the manufacture of photovoltaic (PV) systems such as BSF and PERC cells (Allen et al., 2019), inverters (Zeng et al., 2017), brackets (Lv et al.,

White Aluminum Cast Photovoltaic Inverter Housing for

White Aluminum Cast Photovoltaic Inverter Housing for Household Solar Power Systems No reviews yet Jiaxing Zhulian Electric Appliances Co., Ltd. Custom Manufacturer1 yr CN

Custom Photovoltaic Inverter Aluminum Die Casting Parts

Nov 24, 2023 · Custom Photovoltaic Inverter Aluminum Die Casting Parts Manufacturers With this rise in demand, the need for high-quality and durable equipment, such as photovoltaic inverter

Photovoltaic Inverter Aluminum Die Casting Parts:

The Role of Photovoltaic Inverter Aluminum Die Casting Parts,Photovoltaic inverter aluminum die casting parts are essential for the reliable and efficient operation of photovoltaic systems.

Aluminum For Inverter Housing

Aug 6, 2025 · What aluminum alloys optimize thermal management for 50kW photovoltaic inverters? A356-T6 cast aluminum dominates with 170W/m·K thermal conductivity and 0.5%

Application of aluminum electrolytic capacitor in photovoltaic inverter

Jul 18, 2025 · The role of electrolytic capacitor in photovoltaic inverter can be regarded as a special purpose inverter powered by DC power supply, with an output frequency of 50Hz or

Multi Layer Annealed Photovoltaic Inverter Connection Flexible Aluminum

Aug 18, 2025 · Key features: Prioritize electrical conductivity, typically using high-purity aluminum (e.g., 1060 pure aluminum, conductivity ≥61% IACS) with low impurity content. May be surface

Supply OEM Photovoltaic Inverter Aluminum Die Casting Parts

The backbone of any solar power system, the photovoltaic inverter plays a pivotal role in converting DC electricity generated by solar panels into AC electricity suitable for grid

Inverter Transformers for Photovoltaic (PV) power plants:

Dec 22, 2022 · In this paper, the author describes the key parameters to be considered for the selection of inverter transformers, along with various recommendations based on lessons

Photovoltaic inverter aluminum die casting

Which inverters are suitable for rooftop photovoltaic systems? The on grid inverters HPS and HPT seriesare widely suitable for residential and small-scale commercial rooftop photovoltaic

Flexible Manufacturing Photovoltaic Inverter for Radiator

Jul 23, 2025 · Flexible Manufacturing Photovoltaic Inverter for Radiator Application Parts Aluminum Heat Sink, Find Details and Price about Aluminum Alloy Aluminum Profile

6 FAQs about [Photovoltaic inverter aluminum]

Why is aluminum used in photovoltaic systems?

Aluminum is widely used in the manufacture of photovoltaic (PV) systems such as BSF and PERC cells (Allen et al., 2019), inverters (Zeng et al., 2017), brackets (Lv et al., 2017), and frames (ITRPV, 2022) due to its excellent electrical conductivity and durability.

Is aluminum a good material for solar panels?

With its advantages of light weight, high strength, corrosion resistance and durability, aluminum is widely used in building solar panel frames and photovoltaic supports. Research shows that aluminum is the most widely used material in solar photovoltaic (PV) applications, accounting for more than 85% of most solar PV modules.

Can aluminum be used in a PV system?

Aluminum in assembled PV systems is used for export or domestic installations, and PV systems exported will no longer be within the system boundary. At the end-of-life, domestic PV systems enter the waste management phase. In this study, we focus on the mass of the aluminum element within Al-containing materials.

Does the PV industry rely on imported aluminum materials?

First, we assume that the proportion of imported Al-containing materials used in the PV industry is equal to that of imported Al-containing materials in China. In reality, high-end aluminum materials such as aerospace aluminum alloys, automotive body sheets, and lithium-ion battery aluminum foils still rely on imports (SHE et al., 2020).

How much aluminum is used in photovoltaic systems in China?

The consumption of aluminum (both primary and recycled) for the production of photovoltaic systems accounted for 0.0007 % of China's total aluminum in 2000, and this figure increased to 3.3 % by 2020, representing an approximate 5000-fold increase from the year 2000 (Tables S5 and S8).

Which materials are used in solar PV?

Research shows that aluminum is the most widely used material in solar photovoltaic (PV) applications, accounting for more than 85% of most solar PV modules. Products conform to CEE AAMA, GB, BS, En; CE, DNV, ISO9001 certifications and can provide the TUV and other certifications. Welcome contact

Learn More

- 18 kW photovoltaic inverter

- How big a photovoltaic panel can an inverter carry

- Photovoltaic inverter installation guide

- Tirana Photovoltaic Energy Storage Inverter

- Which inverter is better for photovoltaic use

- Photovoltaic inverter DC

- Price of smart photovoltaic inverter

- Which photovoltaic inverter is better for conversion

- Xia Communication Base Station Inverter Grid-connected Photovoltaic Power Generation System

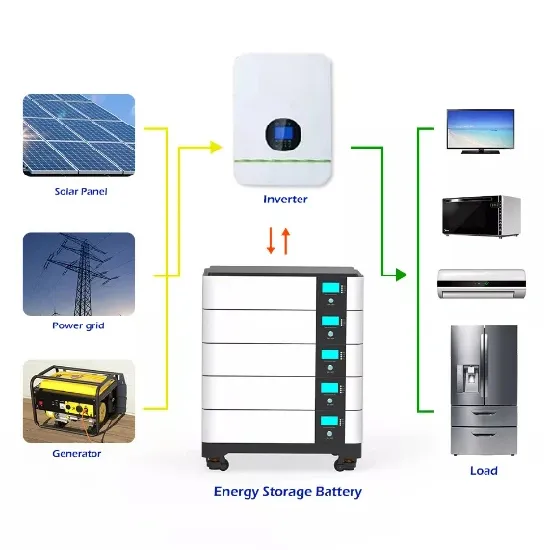

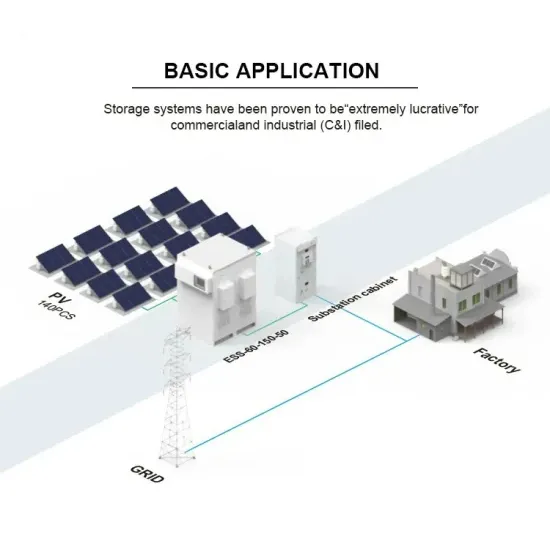

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.