which of these metal is used in storage of batteries › › Basengreen Energy

Conclusion In conclusion, the choice of metal used in the storage of batteries depends on the type of battery and its intended application. Lead, lithium, nickel, and cadmium are all commonly

Understanding Lithium Metal: The Future of

Jul 31, 2024 · Additionally, advanced materials and manufacturing techniques are being explored to produce lithium metal batteries that are both safer and more

Building High-Energy Metal Batteries: From Fundamentals to

May 6, 2025 · Rechargeable metal batteries, which rely on the plating and stripping of active metal ions like lithium, sodium, potassium, and zinc, are heralded as transformative next

Sustainable aqueous metal-air batteries: An insight into

Nov 1, 2022 · To meet the growing demand for sustainable and endurable energy sources, various novel energy conversion and storage systems have emerged and been developed

Battery Technologies for Grid-Level Large-Scale Electrical Energy Storage

Jan 8, 2020 · Grid-level large-scale electrical energy storage (GLEES) is an essential approach for balancing the supply–demand of electricity generation, distribution, and usage. Compared

which of these metals are used in storage batteries

Which Metals are Used in Storage Batteries? Introduction When it comes to storage batteries, various metals play a crucial role in their composition. From traditional lead-acid batteries to

Energy storage batteries: basic feature and applications

Jan 1, 2022 · The energy storage batteries are perceived as an essential component of diversifying existing energy sources. A practical method for minimizing the intermittent nature

Liquid Metal Electrodes for Energy Storage Batteries

May 9, 2023 · The major existing energy storage battery technologies, such as sodium-sulfur bat-teries, redox-fl ow batteries and lithium ion batteries, have been demonstrated for up to MW

Advancements in energy storage: a review of batteries and

Aug 9, 2025 · Energy storage technologies are fundamental to overcoming global energy challenges, particularly with the increasing demand for clean and efficient power solutions.

What is the principle of metal energy storage?

Feb 8, 2024 · The principle of metal energy storage is fundamentally grounded in electrochemistry, focusing primarily on how metals can interconvert electrical

Next-Gen Batteries: The Material Race for Energy Superiority

1 day ago · By enabling the use of lithium-metal anodes, solid-state batteries deliver significantly higher energy density, longer cycle life, and ultra-fast charging capabilities, making them a

Rare earth incorporated electrode materials for advanced energy storage

Jul 1, 2019 · Rare earth is a group of elements with unique properties. Discovering the application of rare earth elements in advanced energy storage field is a great chance to relate rare earth

which metal is used in storage batteries › › Basengreen Energy

In this article, we will explore the different metals used in storage batteries and their significance in battery performance. Lead is one of the most common metals used in storage batteries,

Boosting Energy Storage in Metal Batteries by Light:

Jul 30, 2024 · Inspired by light–matter interactions that might provoke a photoelectric or photothermal effect on light-responsive materials, various light-responsive batteries have been

What metals are needed for energy storage? | NenPower

Sep 24, 2024 · 1. ENERGY STORAGE METALS The landscape of energy storage technologies is rapidly evolving, driven by the urgent need for efficient and sustainable energy solutions. At

Lithium‐Metal Batteries: From Fundamental

Sep 14, 2022 · Lithium-metal batteries (LMBs) are representative of post-lithium-ion batteries with the great promise of increasing the energy density drastically

6 FAQs about [Which metal energy storage batteries]

What are the different types of battery energy storage systems?

The different BESS types include lithium-ion, lead-acid, nickel-cadmium, and flow batteries, each varying in energy density, cycle life, and suitability for specific applications.

What is a battery energy storage system?

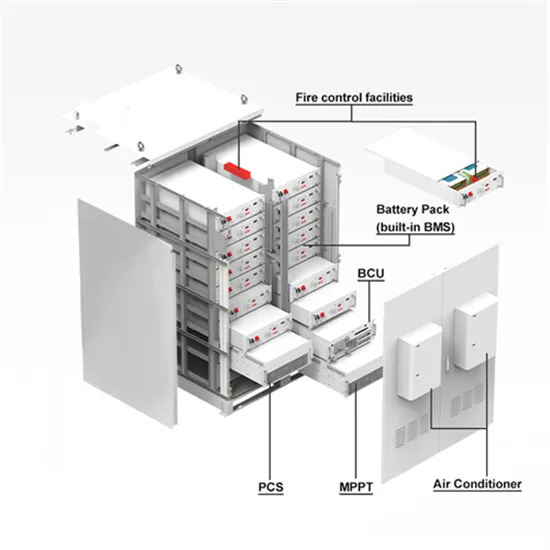

A battery energy storage system, usually known by its acronym BESS, is a simple technology that stores electrical energy in batteries at a household, industrial, or municipal level. This device enhances grid stability, improves energy efficiency, and enables the integration of renewable energy sources.

How many batteries are in a battery energy storage system?

Battery energy storage systems (BESS) store energy from different sources in a rechargeable battery. The total number of batteries depends on several factors: the number of cells per module, the modules per rack, and the racks connected in series. For instance, a BESS can consist of 5,032 modules containing over 100,000 lithium-ion batteries.

Which metal is used in a Bess battery?

Manganese and aluminum are often used in the cathodes of these batteries, contributing to improved durability and safety. Lead is a crucial metal in lead-acid batteries, a traditional but widely used BESS technology, especially in applications where cost is critical.

What is a sodium-sulfur battery?

Sodium-sulfur Batteries: Sodium-sulfur batteries are high-temperature batteries that operate by reacting molten sulfur with molten sodium. They are often used for grid-scale energy storage, particularly in stabilizing power grids with sizeable renewable energy inputs.

What are lithium ion batteries?

Lithium-ion batteries also incorporate cobalt and nickel, which help enhance the battery’s energy capacity and stability. Manganese and aluminum are often used in the cathodes of these batteries, contributing to improved durability and safety.

Learn More

- Which places are suitable for energy storage batteries

- Which units need energy storage batteries

- Which Belmopan energy storage power supply is the best

- Can energy storage batteries drive motors

- The price of discharging energy storage batteries

- How many types of energy storage batteries are there in Indonesia

- Which company in Freetown is good at energy storage power supply

- Which 30kw energy storage company is the best in Kuwait City

- Price of large and small energy storage cabinet batteries

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.