Flexible Substation and Its Demonstration Project

Jun 18, 2020 · Figure 6.3 shows a diagram of a flexible substation for a distribution application. A superior grid means a grid with a higher nominal voltage and/or a large capacity. The flexible

A Review of the Energy Efficiency Improvement in DC

Apr 13, 2019 · Through the results of this extensive review, useful reference and support are provided for the research and development focused on energy efficient traction systems.

Power Control Strategy of Energy Storage System in Substation

Dec 18, 2023 · The hybrid energy storage power sharing strategy presented in this paper not only resolves the shortcomings of existing substation DC systems but also contributes to the

AC/DC system construction and analysis of business model

Nov 1, 2021 · This paper focuses on a novel model named multi-station fusion (MSF). The proposed model integrates transformer substation, data center, energy storage system (ESS),

AT 52_Pre-emptive tripping of distribution power

Dec 7, 2021 · A number of manufacturers offer energy storage devices which can be applied to the tripping coils of specific circuit-breakers in conjunction with self-powered protective relays

Substation DC Auxiliary Supply – Battery And Charger

Sep 21, 2015 · Today, normal DC auxiliary supply systems in power substation are operating on the 110 V or 220 V level. Battery, charger and distribution switchboard are

Energy Storage for Traction Power Supply Systems

Mar 4, 2008 · This paper described an energy storage for traction power supply system that effectively reduces greenhouse gas emissions. Hitachi remains committed to environmentally

(PDF) Analysis of electric-heat characteristics and power storage

Dec 12, 2020 · Analysis of electric-heat characteristics and power storage capacity of emergency power supply in substation based on energy saving and environmental friendly materials

Multi time scale management and coordination strategy for

Mar 1, 2024 · Multi time scale management and coordination strategy for stationary super capacitor energy storage in urban rail transit power supply system

Railway Power Supply Systems

Jul 7, 2022 · In addition to supplying products, Toshiba also provides customers with FTK solutions. One representative example of our FTK, the Taiwan power supply systems, our

Substation DC Auxiliary Supply – Battery And Charger

Dec 20, 2017 · Power substation can have one or several DC systems. Factors affecting the number of systems are the need of more than one voltage level and the need of duplicating

Research on photovoltaic and energy storage systems in substation

Aug 1, 2024 · Firstly, the structure of the PV and energy storage DC substation is described. Secondly, the correspondingly mathematical model of the EI-VDCM control is derived. Then,

6 FAQs about [Is the energy storage power supply of the substation DC ]

What is the role of DC supply in substations?

DC supply in substations plays the role of a reliable source for current supply in the control circuit. It is obtained from the battery, which can store electricity power and continuously supply electricity till it’s not discharged. This makes DC supply an essential component for backup power in substations.

Do portable substations use DC energy?

While most devices and consumer electronics rely on AC energy for power, portable substations continue to operate on DC energy. DC supply has been widely used in substations and portable power applications for many years. The primary reason for using a DC supply in substations is to ensure a continuous power supply throughout the control circuit.

How many DC systems can a power substation have?

Power substation can have one or several DC systems. Factors affecting the number of systems are the need of more than one voltage level and the need of duplicating systems. Today, normal DC auxiliary supply systems in power substation are operating either on the 110 V or 220 V level, though lower levels exist.

Why do substations use DC power?

The primary reason for using a DC supply in substations is to ensure a continuous power supply throughout the control circuit. DC power is reliable, easily directed from a battery source, and facilitates portable substation solutions. DC power remains a reliable source for portable applications.

What voltage is auxiliary supply in a power substation?

Today, normal DC auxiliary supply systems in power substation are operating either on the 110 V or 220 V level, though lower levels exist. Some systems at the substation may require lower voltages as their auxiliary supply source.

What are the uses of DC supply in a power station?

In a power substation, DC supply is used for opening and closing circuit breakers, activating protective relays, isolators, indicator lights, alarm circuits, PLCC (POWER LINE CARRIER COMMUNICATION) panels, and control room emergency lights. Protective devices respond more immediately to DC supply compared to AC.

Learn More

- New Delhi substation energy storage power supply price

- Where is the energy storage power supply in the substation

- Energy storage DC power supply

- Energy storage inverter integrated emergency power supply

- Price of photovoltaic energy storage power supply in Angola

- North Asia Energy Storage Mobile Power Supply

- Cross-border energy storage power supply

- Portable Energy Storage Power Supply in Sydney Australia

- Germany s Sunshine Energy Storage Power Supply

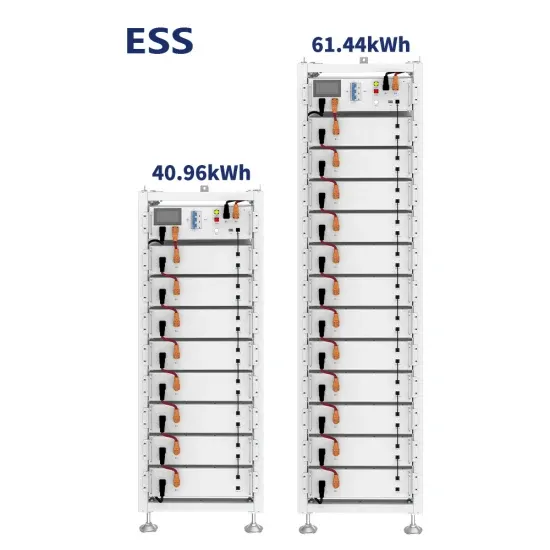

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.