Reduced-Order Modeling of Inverter-Based Generation

Nov 30, 2022 · A commonly used MOR approach in power system mod-eling is singular perturbation, which is based on timescale separation of fast and slow dynamics and assumes

Why Does Power Inverter Output Power Not Reach Rated Power

Jun 12, 2025 · Wondering why your inverter isn''t delivering full power? Learn the top reasons why power inverters fall short of rated output and how to fix them. Expert tips included!

Common Home Inverter and Battery Issues: Causes and Solutions

Mar 4, 2025 · In this guide, we''ll cover the most common inverter issues, their causes, and how to fix them effectively. Causes: Loose or corroded battery terminals. Old or damaged battery.

Seeking advice on proper configuration 12V 140ah

Jul 1, 2015 · The PWM controller just takes the voltage it needs and discards the rest, thus wasting some of the panel power. It does not always make financial sense to pay the premium

Common Home Inverter Problems and How to Fix Them

Jan 21, 2025 · It could be due to various reasons like battery failure, faulty wiring, or an issue with the inverter''s internal components. Causes: Battery is too weak or dead. Fuse or circuit

800VA Pure Sine Wave Inverter''s Reference Design

Apr 1, 2023 · The pure Sine Wave inverter has various applications because of its key advantages such as operation with very low harmonic distortion and clean power like utility-supplied

Reduced-order modeling of inverter-based generation using

Jan 1, 2021 · This paper contributes to the field of inverter modelling for large-scale simulations by introducing a novel Model-Order Reduction (MOR) method based on singular perturbation.

Solar Inverters_Energy Storage inverters

Solis is one of the world''s largest and most experienced manufacturers of solar inverters supplying products globally for multinational utility companies, commercial & industrial rooftop

Troubleshooting Inverter Problems: A Step-by-Step Guide

Nov 25, 2023 · Inverters play a crucial role in many modern systems, converting DC power from sources like batteries or solar panels into AC power that can be used by household

Troubleshooting Inverter Problems: A Step-by-Step Guide

Nov 25, 2023 · If your inverter turns on but doesn''t produce any output power, consider these steps: Verify the Load: Ensure that the load connected to the inverter is within its rated capacity.

Design issues in ultra-fast ultra-low-power superconductor

Jul 1, 1997 · The results are presented of the feasibility study of ultra-fast low-power superconductor digital switches based on Rapid Single-Flux-Quantum (RSFQ) technology.

10 common inverter failure and the solutions – TYCORUN

Nov 15, 2023 · When some inverter failure occurs in the system, how to troubleshoot the causes and repair it in time? This article will give you an overall guide. 1. No display on the inverter

6 FAQs about [Inverter discards power]

What are the most common power inverter problems?

Over 60% of inverter failures stem from preventable problems such as loose connections, overloaded circuits, or poor maintenance. This guide takes an in-depth look at the most common power inverter problems faced by users and provides actionable solutions backed by specialized knowledge.

How to choose a good inverter?

Inverters come in different sizes and wattage capacities to handle varying power loads. It’s crucial to choose an inverter that can comfortably meet the wattage requirements of the devices you need to power. Overloading the inverter by connecting appliances that draw too much power is a frequent cause of problems. 1. Inverter Won’t Turn On

How to control the battery capacity of an inverter?

Solution: Control the number of devices connected to ensure that the total power does not exceed 80% of the rated value of the inverter. Recalculate the system configuration, select the battery capacity according to the principle of “load power x 1.2,” and reserve 20% redundancy.

What does an inverter do?

An inverter converts direct current (DC) power, like from a car battery or solar panels, into alternating current (AC) power that can be used to run standard electrical devices. Inverters come in different sizes and wattage capacities to handle varying power loads.

Are home inverters a problem?

Inverters are essential components of modern homes, especially in areas where power cuts are frequent or in homes relying on solar energy systems. These devices help convert DC (direct current) into AC (alternating current) so that you can power your appliances. However, like any electrical equipment, home inverters can face problems.

Why does my inverter keep turning off?

Many inverters have displays that show error codes when there’s a problem. Causes: Solutions: 6. Inverter battery not charging Sometimes the battery doesn’t charge even when main power is on. Causes: Solutions: 7. Inverter shutting off frequently If your inverter keeps turning off on its own, there’s likely a problem. Causes: Solutions: 8.

Learn More

- Xia Communication Base Station Inverter Grid-connected Photovoltaic Power Generation System

- Electricity storage high power inverter

- Photovoltaic power station inverter control cabinet

- Moldova power inverter manufacturer

- Nordic communication base station inverter photovoltaic power generation equipment

- DC remote power supply module as inverter

- Bahamas Photovoltaic Power Station Inverter

- Inverter current power 11 kW

- Site requirements for solar power frequency inverter

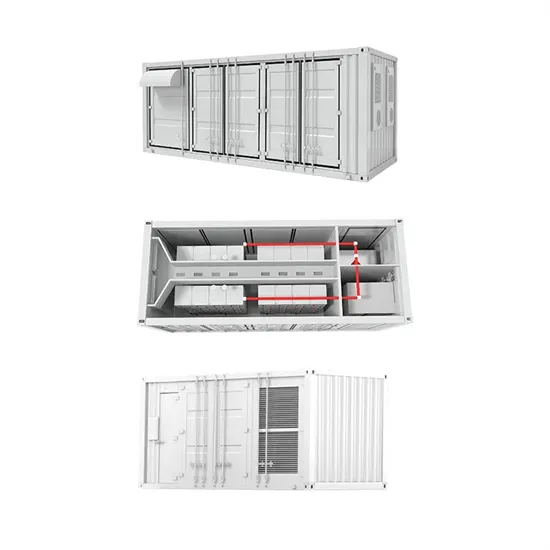

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.