National Blueprint for Lithium Batteries 2021-2030

Jul 1, 2024 · Establishing a domestic supply chain for lithium-based batteries requires a national commitment to both solving breakthrough scientific challenges for new materials and

Review of energy storage systems for vehicles based on

Jan 1, 2021 · Cost analysis of electric vehicles and their future trends in comparison with conventional vehicles. Evaluation of most commonly used energy storage systems for electric

2025 Incremental Purchase Cost Methodology and

Jan 13, 2025 · DOE calculated the incremental cost for each clean powertrain for different vehicle types/classes across light, medium and heavy-duty vehicles by focusing on powertrain

Battery prices continue to drop, lowering the

Jul 18, 2024 · The price of lithium-ion batteries in China has decreased by 51 percent in the past year. Lower battery prices make electric vehicles cheaper

The future cost of electrical energy storage based on

Jul 10, 2017 · Cost projections based on experience rates and S-curve type market growth assumptions for consumer electronics, hybrid electric vehicles, electric vehicles, residential

Cost Projections for Utility-Scale Battery Storage: 2023

Jul 25, 2023 · Executive Summary In this work we describe the development of cost and performance projections for utility-scale lithium-ion battery systems, with a focus on 4-hour

How much is the factory price of solar electric vehicles

May 7, 2024 · 1. The average factory prices for solar electric vehicles range from $20,000 to $50,000, based on specifications and capabilities. 2. Several manufacturers are emerging in

Energy management in integrated energy system with electric vehicles

Oct 30, 2024 · The integrated energy system with electric vehicle charging station via vehicle-to-grid aims to offer a proactive solution for low-carbon development

Electric vehicles in China: BYD strategies and government subsidies

Jan 1, 2016 · China became the largest car producer in 2009 and it is strongly investing in the manufacturing of electric vehicles. This paper examines the incentives provided by Chinese

The battery industry has entered a new phase –

Mar 5, 2025 · At the same time, the average price of a battery pack for a battery electric car dropped below USD 100 per kilowatt-hour, commonly thought of

Energy storage technology and its impact in electric vehicle:

Jan 1, 2025 · The desirable characteristics of an energy storage system (ESS) to fulfill the energy requirement in electric vehicles (EVs) are high specific energy, significant storage capacity,

Indonesia Electric Vehicle Outlook 2023

Feb 21, 2023 · Switching to electric vehicles (EV) is a key strategy to road transportation decarbonization, as it has the potential to reduce emissions concurrently with the power sector

What is the price of a large energy storage vehicle?

Apr 23, 2024 · The cost of a large energy storage vehicle can vary significantly based on multiple factors. 1. Vehicle type and specifications, 2. Battery capacity, 3. Manufacturer, 4. Market

Energy Management Systems for Electric Vehicles: A

Feb 29, 2024 · As the demand for electric vehicles (EVs) continues to surge, improvements to energy management systems (EMS) prove essential for improving their efficiency,

2025 Incremental Purchase Cost Methodology and

Jan 13, 2025 · As in the 2022 analysis, vehicle modeling was conducted utilizing the DOE Autonomie model, managed by Argonne National Laboratory, to model a "representative"

Storage technologies for electric vehicles

Jun 1, 2020 · The advanced charging systems may also play a major role in the roll-out of electric vehicles in the future. The general strategies of advanced charging systems are explained to

Tesla''s energy storage business continues to boom

Jan 4, 2025 · While Tesla''s vehicle delivery results were disappointing, there was still good news in the report: Tesla''s energy storage business continues to boom. Originally, at the beginning

The Real Cost of Manufacturing Energy Storage Vehicles:

Feb 25, 2025 · Here''s a dirty secret: modern energy storage vehicles contain more code than a dating app. The typical breakdown looks like: Fun fact: The "oops buffer" isn''t an official line

Life cycle carbon emission and cost-effectiveness analysis of electric

Feb 1, 2023 · Electric vehicles play an important role in energy transition and low-carbon development. It is important to evaluate the energy-saving emission reduction and cost

Tesla begins production at Shanghai Megapack Factory

Feb 11, 2025 · Each Megapack unit weighs 38 tons and can store over 3.9 MWh of energy, sufficient to power approximately 3,600 households for one hour. Production at the plant is set

What Are the 9 Operating Costs of Electric Car

Jul 24, 2025 · Discover the nine key operating costs in electric car manufacturing. Get expert insights and actionable tips-download our free cost template now.

Decoding EV Energy Storage Costs: What Drives Battery Prices

Jul 21, 2024 · As EV adoption skyrockets globally (with 14 million sold in 2023 alone), understanding battery pricing isn''t just for engineers anymore – it''s becoming dinner table

Energy Storages and Technologies for Electric Vehicle

Feb 7, 2021 · The transport sector is heading for a major changeover with focus on new age, eco-friendly, smart and energy saving vehicles. Electric vehicle (EV) technology is considered a

The electric vehicle energy management: An overview of the energy

Jul 1, 2021 · Through the analysis of the relevant literature this paper aims to provide a comprehensive discussion that covers the energy management of the whole electric vehicle in

Review of electric vehicle energy storage and management

Sep 1, 2021 · The energy storage section contains the batteries, super capacitors, fuel cells, hybrid storage, power, temperature, and heat management. Energy management systems

Electric vehicle battery closed-loop supply chain pricing and

Dec 1, 2024 · Results show that: (1) The factory price, selling price, collection price, and carbon emission mitigation scale of power batteries are affected by cap-and-trade and reward-penalty

6 FAQs about [Factory price of electric energy storage vehicle]

What are the different types of energy storage solutions in electric vehicles?

Battery, Fuel Cell, and Super Capacitor are energy storage solutions implemented in electric vehicles, which possess different advantages and disadvantages.

Do electric vehicles cost more?

While electric vehicles already have a lower cost for fuel and maintenance than vehicles with internal combustion engines, this report seeks to document the difference in up front purchase cost between conventional and clean vehicles to further inform consumers and others on these developments.

What is energy storage in EVs?

In EVs, the type of energy storage is, together with the drive itself, one of the crucial components of the system.

What are alternative energy storage for vehicles?

Another alternative energy storage for vehicles are hydrogen FCs, although, hydrogen has a lower energy density compared to batteries.

How much energy does a Megapack store?

Each Megapack unit weighs 38 tons and can store over 3.9 MWh of energy, sufficient to power approximately 3,600 households for one hour. Production at the plant is set to scale up in the first quarter of 2025, with a target annual output of 10,000 units, equivalent to nearly 40 GWh of BESS capacity per year.

Are battery electricity storage systems a good investment?

This study shows that battery electricity storage systems offer enormous deployment and cost-reduction potential. By 2030, total installed costs could fall between 50% and 60% (and battery cell costs by even more), driven by optimisation of manufacturing facilities, combined with better combinations and reduced use of materials.

Learn More

- Electric Energy Storage Vehicle Customization Price

- Ashgabat energy storage vehicle factory price

- Sana Energy Storage Electric Vehicle Charging Station

- How much is the price of commercial energy storage cabinet factory in Turkmenistan

- What is the factory price of energy storage vehicles in Croatia

- What is the wholesale price of Montenegro mobile energy storage vehicle

- Wholesale price of mobile energy storage vehicle in Busan South Korea

- What is the price of Ankara commercial energy storage cabinet factory

- Huawei energy storage vehicle price in Manchester UK

Industrial & Commercial Energy Storage Market Growth

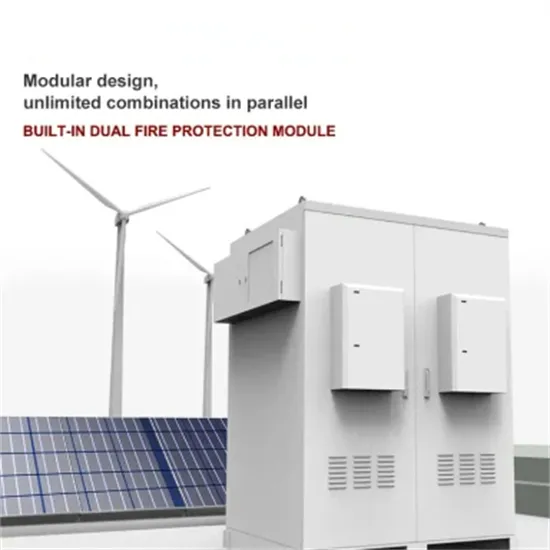

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

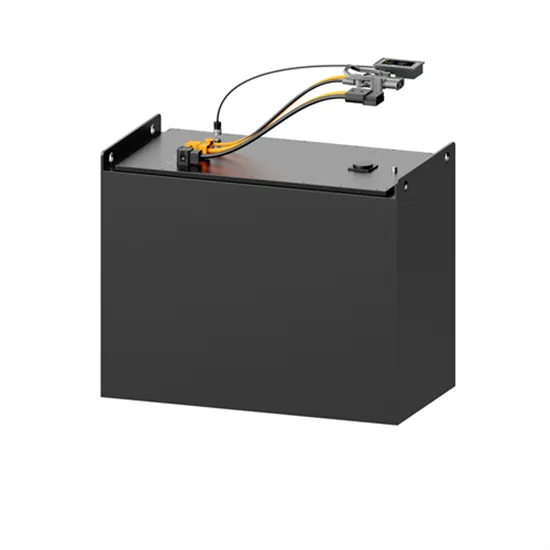

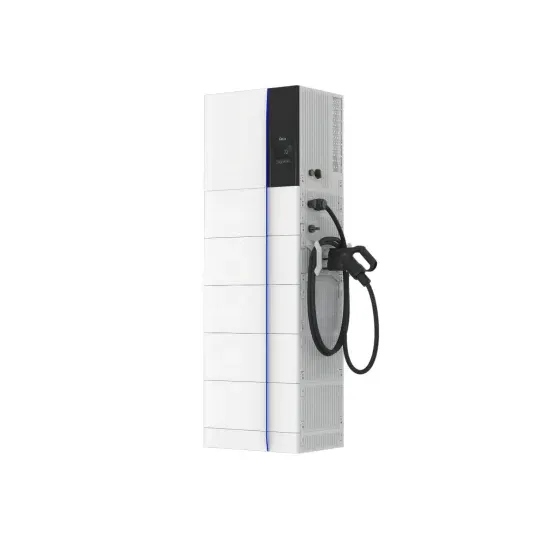

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.