Photovoltaic panel gap glue maintenance is difficult

Photovoltaic (PV) panels are devices that convert sunlight into electrical energy using semiconductor materials. This process is known as the photovoltaic effect. PV panels are an

Step-by-Step Guide to Repair Cracked Solar Panels

Jul 30, 2025 · These kits typically contain a polishing compound and a buffing pad that can be used to remove superficial damage and restore the glass to its

Soiling, cleaning, and abrasion: The results of the 5-year photovoltaic

Sep 15, 2024 · The Fill Holes subroutine was applied to fill pixels within image objects suspected to remain incomplete after the thresholding operation, e.g., filling doughnut holes.

What Is Fill Factor in Solar Cells? A Key Metric

May 23, 2024 · The importance of fill factor in solar technology shows in its key role in photovoltaic performance. Solar cells with a good fill factor do better at

Enhanced thermal performance of photovoltaic panels based on glass

Nov 1, 2021 · Therefore we conclude that only holes and pyramids are suitable candidates as glass surface texturing for radiative cooling applications in solar panels. Pyramids are better

Transparent & Tempered Solar Panel Glass, Photovoltaic Glass

New Way photovoltaic solar panel glass features High light-transmittance, Strong Hardness, Aesthetic Improvement, Light-weight, and Customizable. Contact the leading solar glass

Experimental repair technique for glass defects of glass-glass

Aug 1, 2023 · A failure of growing importance is the defect in the glass layer (s) of glass-glass PV modules. In this research, an experimental glass repair technique for glass-glass PV modules

Specifications for filling gaps in photovoltaic panels

the mounted aluminum framed PV panels (i.e., other PV technologies or ground mount systems), EPA recommends that an installer certified by the North American Board of Certified Energy

Solar Photovoltaic Glass: Classification and

Jun 26, 2024 · Demand for solar photovoltaic glass has surged with the growing interest in green energy. This article explores ultra-thin, surface-coated, and

Transparent Solar Panels: The Future of Clean Energy?

Jul 2, 2025 · Yes, see through solar panels, also known as transparent solar panels or solar glass, are available in limited commercial applications. Researchers and manufacturers have

A second life for solar panels with glass defects

Jul 18, 2023 · Filling in the Cracks Tas emphasizes that it is not sufficient to simply fill in a crack in a solar panel with this resin. "You also need to make sure that no water seeps through

A facile photolithography process enabling pinhole-free thin

Mar 1, 2023 · One of the major obstacles with thin film PV device scale-up is the presence of pinholes that act as sink holes for carriers, impeding utilization of the full coating area. Another

A comprehensive review on the recycling technology of

Apr 5, 2024 · Recycling PV panels through e-waste management is crucial step in minimizing the environmental impact of end-of-life PV systems such as the release of heavy metals into the

what is a hole flow in a photovoltaic cell

Understanding the Hole Flow in a Photovoltaic Cell What is a Photovoltaic Cell? Photovoltaic cells, also known as solar cells, are devices that convert light energy directly into electrical

What are Solar Cells and Solar Panels Made of?

Nov 24, 2024 · A standard solar panel includes a glass casing at the front to add durability and protection for the silicon photovoltaic (PV) cells. Under the glass exterior, the panel has a

Emerging innovations in solar photovoltaic (PV)

Light-absorbing materials play a pivotal role in solar PV technologies. Photovoltaic cells convert sunlight into electricity using semiconducting materials that exhibit the photovoltaic effect. Key

Top 5: Factors Responsible for Glass Breakage in

Mar 13, 2025 · In a highly competitive solar industry, cost of production, handling, and installation gives the business an edge over competitors. Modern PV

Highly transparent, superhydrophobic, and durable

Jul 20, 2024 · The ongoing effort to reduce the cost of PV panels while enhancing their efficiency has led to a continuous decrease in panel thickness, necessitating the use of glass in the

How To Fix A Small Hole In A Glass Window

Mar 4, 2022 · You can fix a small hole in window glass by filling it with a clear filler and then scraping the repair flat and polishing it with toothpaste and window

CEA recommendations for mitigating glass breakage – pv

Jul 28, 2025 · Clean Energy Associates has investigated glass breakages at utility-scale solar sites across three continents. It has found that there isn''t a single root cause, but a perfect

Photovoltaic panel assembly installation holes

Jul 8, 2020 · The mechanical and electrical installation of PV systems should be performed in accordance with all applicable codes, including electrical codes, building codes and electric

CEA recommendations for mitigating glass breakage – pv

Jul 28, 2025 · In cases seen by Jörg Althaus, director of engineering and quality assurance at Clean Energy Associates (CEA), it starts with a few panels – then dozens, hundreds, even

How to Repair the Gap in the Photovoltaic Panel Glass Door:

Let''s be real - when you notice a hairline crack in your solar panel glass door, it''s tempting to channel your inner ostrich and bury your head in the sand. But here''s the kicker: that innocent

How to Repair a Hole in Fiberglass Parts Like a Pro

Feb 29, 2024 · When the calm of the water or the open road is interrupted by an unexpected tear or hole in your fiberglass vessel or vehicle, it''s not the end of

6 FAQs about [Filling holes in photovoltaic panel glass]

How thick is a glass-glass PV module?

2.2. Glass characteristics Glass-glass PV modules generally use 2–3 mm thick glass layers, since thicker glass layers negatively impact the module's weight and costs, while trends are to reduce glass thickness to below 2 mm [ 10 ].

Are glass-glass PV modules a problem?

Unfortunately, glass-glass PV modules are, similar to regular PV modules, subject to early life failures. A failure of growing concern are defects in the glass layer (s) of PV modules. The scale of decommissioned PV modules with glass defects will increase with the development of solar PV energy [ 7 ].

Can PV modules survive a glass defect?

However, glass defects do not directly imply that PV modules endure internal damage nor that PV modules cannot continue to operate with minimal microcracks. Thus far, glass defects have been regarded as a failure beyond repair and no noticeable attempt has been made to develop reparation methods.

Why do PV modules need glass panels?

The replacement of the back sheet layer with a glass panel drastically reduces the proneness to water penetration. Ingress of water (vapor) at glass-glass PV modules is negligible and restricted to the edge area only [ 18 ].

How do glass defects affect a PV system?

Glass defects impact the economic performance of a PV system in multiple ways. The most obvious effect is the potential (in)direct performance loss of PV modules, which results in reduced economic revenues. Secondly, PV modules that suffer from glass defects may no longer meet safety requirements, therefore these modules are replaced.

How are glass defect PV modules treated?

After the initial tests, the glass defect PV modules were divided into two subgroups: repaired specimen and non-repaired specimen. The repaired specimen were treated with the experimental repair technique, whereas the non-repaired specimen were left untreated as reference.

Learn More

- Luxembourg glass photovoltaic panel manufacturer

- Photovoltaic glass panel requirements

- How much does a glass photovoltaic panel cost in San Diego

- Huawei photovoltaic glass panel manufacturing

- Photovoltaic panel glass greenhouse

- Netherlands glass photovoltaic panel manufacturer

- Small photovoltaic panel manufacturer in Accra

- Majuro rooftop photovoltaic panel manufacturer

- Glass photovoltaic panels in Karachi Pakistan

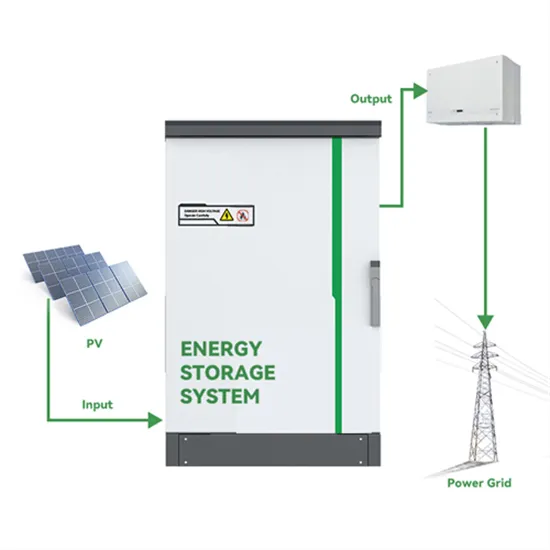

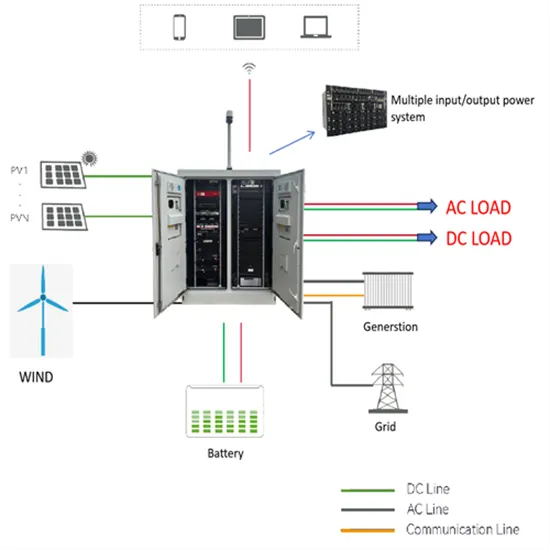

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.