Inverter Efficiency: Understanding How Much Power You''re

Jul 21, 2025 · Most modern inverters have efficiency ratings between 90% and 98%. Let''s break it down: If you feed 1000 watts of DC power into your inverter and it outputs 950 watts of AC

How Many Watts Does an Inverter Refrigerator Use: A Closer

May 28, 2024 · An inverter refrigerator is a popular appliance that helps us keep our food fresh and cool. However, one question that often arises is, "How many watts does an inverter

How Much Power Does a Solar Inverter Need

Dec 7, 2024 · To calculate the average electricity consumption, it is around 1.2-1.5 units per hour. So, if you plan to use it for 8 hours straight in a day, it will

Solar inverter parameters:How much do you know

Dec 9, 2021 · Solar inverter is one of the most vital components of a solar power system. It is a device that converts direct current (DC) from the solar panels into alternating current (AC)

Understanding the Power Consumption of Inverter Refrigerators: How Many

How Many Watts Does an Inverter Refrigerator Use? To understand how many watts an inverter refrigerator uses, we first need to comprehend what ''watts'' signifies in terms of energy. Watts

What Is a Power Inverter? | Types, Capacity,

Jul 6, 2022 · Learn all about power inverters and how they work. Also, discover the different types and some of the many ways you can put a power inverter to

Frequently Asked Questions about Inverters

Frequently Asked Questions about Inverters How much battery capacity do I need with an inverter? As a rule of thumb, the minimum required battery capacity for a 12-volt system is

Inverters in Electric Vehicles: Powering the Next Generation

Sep 9, 2024 · Learn how inverters in electric vehicles power the next generation of transportation by converting DC to AC, optimizing efficiency, and supporting renewable energy integration.

How Much Power Does an 850 VA Inverter Use?

Jun 13, 2024 · Knowing the power consumption of an inverter is crucial when designing and operating off-grid or backup power systems. It helps determine the appropriate battery bank

Efficiency of Inverter: Calculation & Equation Guide

Jun 22, 2022 · The efficiency of an inverter refers to the amount of AC output power it provides for a given DC input. This normally falls between 85 and 95 percent, with 90 percent being the

Inverter Usage Calculator & Formula Online Calculator Ultra

Oct 3, 2024 · Traditionally, power inverters were used in off-grid locations, but they have since become common in residential and industrial settings to handle frequent power outages and

What Does a Solar Inverter Do? Key Function

Mar 28, 2025 · AC power is the standard form of electricity used in most electrical systems around the world. Household appliances and devices are built to run

How Much Power Will an Inverter Use: Everything You Need

Jul 22, 2025 · If you''re considering investing in an inverter, it''s important to have a good understanding of its power consumption. After all, power consumption plays a significant role

How many inverters are needed for a photovoltaic project

3. How do photovoltaic inverters affect the overall efficiency of a solar power system? Photovoltaic inverters play a crucial role in solar power system efficiency. High-quality inverters efficiently

Inverter Power Draw: How Much Power Does an Inverter Use

Mar 17, 2025 · An inverter draws power from a battery depending on its efficiency, typically over 92%. For a connected load of 250 watts, the inverter uses less than 270

Understanding Inverter Input And Output: What

3 days ago · The inverter output is the electrical power generated by the inverter from the process of converting the DC input source into alternating current

6 FAQs about [How much inverter power is generally used]

How much power does an inverter use?

When you include the idle power consumption of the inverter with it's conversion inefficiency while powering small loads, 50-150W, 55-70% efficient is a good number. Many units have a "low power" option where idle power consumption is decreased; however, those are only useful if you have NO loads whatsoever on the unit.

What is the difference between a power inverter and a solar inverter?

Solar inverters or power inverters both have the same function with one slight difference. Solar inverters take direct current from solar panels and transfer the converted current to solar batteries. Whereas normal inverters take current from batteries and transfer the alternating current to the connected appliances.

Are expensive inverters better?

1. More expensive inverters will tend to have higher conversion efficiency and lower no load draws Watt for Watt compared to similar budget models. 2. Most quality inverters will have low power 'eco' modes, but there are caveats to these modes from what I've heard 3. Higher power inverters tend to have higher no load draw 4.

How much power does a 12Kw inverter use?

My 18kw inverter can handle 3X the surge current (54kw) for 20seconds. This is the most important spec to me. It also uses about 300 watts/hr idle power. But the 12kw model which is 33% smaller still uses 270 watts. I just figure one extra solar panel to power the inverter. If you have a lot of heavy loads, it's not a big deal.

Do inverters consume a lot of power?

In case the inverters are fully charged they hardly consume less than 0.99% of their capacity. With this, there is little to no impact on the power bills. Also, it would be better if you switched off the inverter when fully charged. But if using it at full speed while it is plugged in it will consume more power.

How many watts in a 24V inverter?

Power drawn = 24V * 0.4 = 9.6 watts This formula and calculation are applicable to all inverters irrespective of their size. 12V or 24V is the only thing that will make the difference in the power consumed. Remember, the higher the voltage is the greater the no-load current will be.

Learn More

- How much power does a 1 300 watt inverter have

- How much power inverter can ee85 make

- How big an inverter should a 35kw power station be equipped with

- How big an inverter can a 60a power supply be

- How big a lithium battery can be used with an inverter

- Can the power from the inverter be used for home use

- How is the photovoltaic power generation of the Tehran communication base station inverter

- How many capacitors are generally used in 5g base stations

- How long can the energy storage inverter supply power

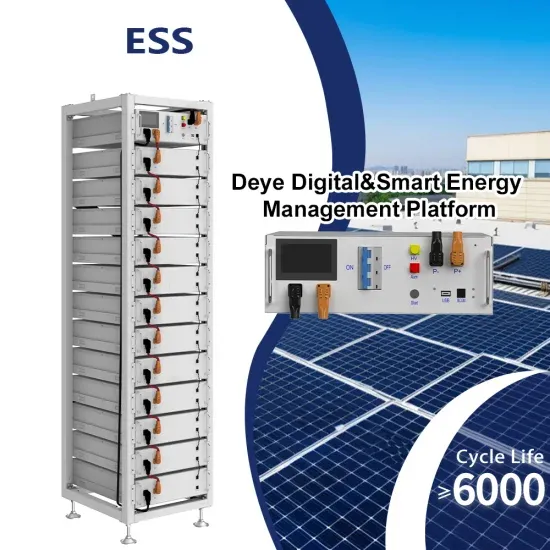

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.