Extrusion process principle of energy storage charging pile

Can battery energy storage technology be applied to EV charging piles? In this paper, the battery energy storage technology is applied to the traditional EV (electric vehicle) charging piles to

Battery Pack Assembly Process Series 2

May 21, 2025 · The insulating sheet and thermal insulation sheet are generally pasted alternately between the battery cells of the module to ensure that the battery cell temperature is balanced

Prismatic Battery Double-Module Extrusion Machine: Dual

Jun 9, 2025 · Maximize battery production efficiency with SunKaLead''s fully automatic prismatic battery double-module extrusion machine. Dual-station operation, PLC precision control, and

Double Module Extrusion Machine for Lithium-Ion Batteries:

Jun 11, 2025 · Maximize energy density and safety with Guangdong Sungalead''s fully automatic Double module extrusion machine. PLC-controlled precision + real-time pressure sensing for

Battery Pack Module Stacking Pressing & Extrusion Machine

Guangdong Songke Leading Intelligent Equipment Co., Ltd. is a enery equipment intelligent manufacturer and solutor of new energy equipment integrating technology research and

How Battery Extrusion Machine Improve Pack Safety

Jul 19, 2025 · Learn how Semco''s Battery Extrusion Machine enhances battery pack safety and strength by reducing gaps, ensuring alignment, and preventing internal stress during assembly.

Energy storage battery module extrusion shaping

Lithium-ion Battery Energy Storage Systems (BESS) have been widely adopted in energy systems due to their many advantages. However, the high energy density and thermal stability

Prismatic Lithium Battery Module Stacking Extruder Energy Storage

Product descriptions from the supplier Manufacturer handheld prismatic Battery Module Stacking And Pressing Machine Binding battery Manual strapping machine Equipment advantage: 1,

Solar Panel Aluminum Frames: Aluminum Extrusions for Renewable Energy

Jun 5, 2025 · In energy transmission and distribution systems, aluminum extrusions play supporting roles in housing, protection, and structure. Electrical Enclosures: Protecting

Energy storage module extrusion effect

What is extrusion based printing? Extrusion-based printing is time-consuming, easily controllable, and repeatable in preparing the fiber-shaped energy storage devices with coaxial structure.

Shanghai Zonzsin Intelligent Equipment Co., Ltd.-Power Battery

Shanghai Zonzsin Intelligent Equipment Co., Ltd. focuses on serving the power battery, energy storage system industry and photovoltaic industry, providing customers with professional

Module Extrusion and Steel Band Sleeving Station

Today, we continue to introduce the production line knowledge of Huiyao Laser''s square-shell battery module PACK production line. On Huiyao Laser''s power battery and energy storage

How Battery Extrusion Machine Improve Pack Safety

Jul 19, 2025 · Extrusion solves these problems by compressing the pack into a rigid, unified form, reducing gaps and securing every cell in place. It also prepares the pack for subsequent

Energy Storage Equipment, Energy storage solutions,

Huijue Group offers industrial and commercial energy storage, PV-BESS -EV Charging, Off-grid / On-grid Microgrid, telecom site solutions, and home solar energy storage, ensuring reliability,

Energy storage battery stacks extrusion device

This energy storage module stacks extrusion device can fix a position the energy storage module through absorption and the multiple spacing mode of butt clamp, improves the stability of

What is an energy storage module?

What is Automatic production line for cylindrical lithium-ion battery commercial and industrial energy storage module pack ? Lithium battery module fully automatic assembly line is mainly

Prismatic Lithium Battery Module Stacking Extruder Energy Storage

Extrusion process description Embedded steel stripp Cell stacking extrusion Steel strip sleeve Pinch online Technical Parameter Equipment weight applicable battery cells Appearance color

Energy storage charging pile module extrusion test

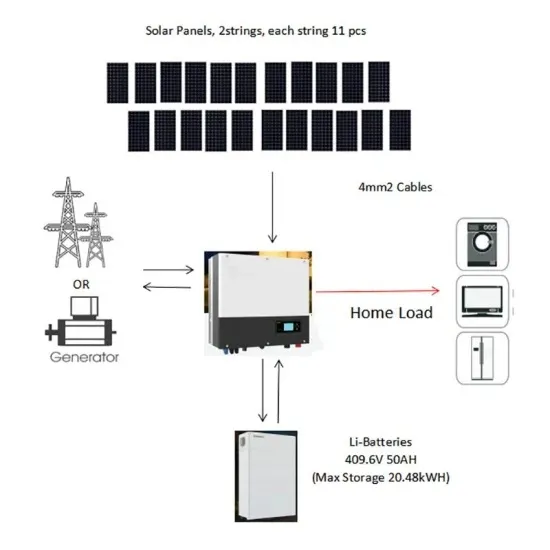

Benefit allocation model of distributed photovoltaic power Table 1 Charging-pile energy-storage system equipment parameters Component name Device parameters Photovoltaic module

energy storage battery module extrusion force

Replacement or expansion of residential energy storage battery module Before adding a new battery module the battery modules in use need to be charged or discharged to match the

Energy Storage Module Extrusion Equipment Workbench

Summary: Discover how advanced extrusion equipment workbenches revolutionize energy storage module production. This article explores cutting-edge technologies, industry

Detailed explanation of the automatic stacking and extrusion

Sep 10, 2024 · Under the background of the rapid development of new energy vehicles and energy storage systems, battery modules, as their core components, the refinement and

Module Extrusion and Steel Band Sleeving Station

Aug 15, 2024 · Today, we continue to introduce the production line knowledge of Huiyao Laser''s square-shell battery module PACK production line. On Huiyao Laser''s power battery and

Detailed explanation of the automatic stacking and extrusion

Under the background of the rapid development of new energy vehicles and energy storage systems, battery modules, as their core components, the refinement and automation level of

4 FAQs about [Energy storage module extrusion equipment]

Who is Tu Energy Storage Technology (Shanghai)?

Safe operation and system performance optimization. TU Energy Storage Technology (Shanghai) Co., Ltd., founded in 2017, is a high-tech enterprise specializing in the research and development, production and sales of energy storage battery management systems (BMS) and photovoltaic inverters.

What is BMS + industrial and commercial energy storage inverter?

The complete set of energy control solutions of "BMS + industrial and commercial energy storage inverter" is suitable for industrial parks, backup power, photovoltaic storage, wind storage and other application scenarios to ensure the safety of industrial and commercial battery systems. Safe operation and system performance optimization.

What are Huijue group's energy storage solutions?

Huijue Group’s energy storage solutions (30 kWh to 30 MWh) cover cost management, backup power, and microgrids. To cope with the problem of no or difficult grid access for base stations, and in line with the policy trend of energy saving and emission reduction, Huijue Group has launched an innovative base station energy solution.

Why should you choose dauntu energy storage?

There are many stringent requirements on the security and reliability of BMS, and dauntu energy storage has made full preparations. From core chip selection to system-level architecture, we guarantee the safety and reliability of battery products in an all-round and real-time manner.

Learn More

- Zambia energy storage module equipment

- Victoria Energy Storage Module Equipment Manufacturer

- Monaco energy storage module equipment production

- Industrial and Commercial Testing Energy Storage Equipment

- Tuvalu lithium battery energy storage equipment company

- Mexican Monterrey energy storage equipment prices

- Singapore new energy storage equipment manufacturer

- 100 kWh energy storage equipment

- Spanish intelligent energy storage cabinet equipment

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.