Basic principles of regenerative drive operation

Mar 22, 2016 · In this post we offer an introductory overview of regenerative drive operation (also referred to as "Active Front End" or "AFE"), covering the basic

Intermediate Voltage Regulation for Total Harmonic

Apr 22, 2019 · Two-stage inverters composed of the front DC-DC stage and the rear DC-AC stage are broadly employed for the current tracking. Structures vary according to the different control

Impedance characteristics investigation and oscillation

Aug 1, 2022 · The model includes the PV arrays, front-end Boost converter, and rear-end inverter with output LCL filter. The impedance modeling of the PV inverter is derived at different

Three-phase inverter reference design for 200-480VAC

May 11, 2022 · This reference design is a three-phase inverter drive for controlling AC and Servo motors. It comprises of two boards: a power stage module and a control module.

How to generate PWM waves of front and rear stages of two

May 5, 2016 · I am working on a two-stage non-isolated photovoltaic grid-connected inverter, with a boost circuit in the front stage and an inverter circuit in the back stage. I use two interrupts in

IDEALPLUSING | Principle of high frequency inverter rear stage

Principle of the circuit diagram of the rear stage of the high-frequency inverter The basic function of the rear stage circuit is to invert the high-voltage DC boosted by the front stage into AC.

Design and Analysis of High-Gain Switched-Capacitor

1, the SCI booster (front stage) and DC-link inverter (rear stage) are connected in cascade between VS and Vo . The main function of the front stage is to obtain a step-up voltage of 4V

The Inverter Stage: Unlocking the Power of Power Electronics

Jan 17, 2024 · The inverter stage is the "muscle" of the drive – a power electronics block that provides the regulated, conditioned power directly to the motor, driving it in the manner

A Comprehensive Review on Matrix-Integrated Single-Stage

Jan 4, 2024 · Our study provides a comprehensive analysis and classification of matrix-integrated isolated single-stage MF/HF AC-AC converters, DC-AC inverters, and AC-DC rectifier

Design and Analysis of High-Gain Switched-Capacitor

2.1 Power Part: As in the power part of Fig. 1, the SCI booster (front stage) and DC-link inverter (rear stage) are connected in cascade between VS and Vo . The main function of the front

A single-stage AC-AC solid-state transformer with ZVS

Jun 15, 2024 · In this paper, a single-stage alternative current (AC)-AC SST solution without bulky energy storage elements is presented. The front-end rectifier (FER) and rear-end inverter

Analysis and Design of a Single-Stage Bridgeless

Mar 27, 2024 · ABSTRACT This paper proposes a single-stage bridgeless isolated AC-DC power factor correction (PFC) topology, and this topology can realize the function of step-up and the

Design Priorities in EV Traction Inverter With Optimum

Apr 1, 2023 · ABSTRACT This technical white paper explores key system trends, architecture, and technology for traction inverters. The devices and technologies used to enable traction

Research on Two-stage Isolated AC–DC Converter with PSO

Oct 18, 2023 · AC–DC converter has the advantages of high power density, stable output, easy to control, etc., and is widely used in many industrial fields. In this paper, the two-stage isolated

Power Inverter 5000 Watt Pure Sine Wave Inverter High-Power Rear Stage

About this item This product is a high-power sine wave inverter board, which can be used for solar inverter conversion, modified wave inverter to sine wave inverter, high frequency square wave

Comparison of Coordinated Control between Front and Rear Stages

Isolated AC-DC solid-state transformers widely use the front and rear multi-stage cascade structure of the bidirectional converter. Due to the difference in the control bandwidth of the

Suppression of the second harmonic current and

Apr 25, 2013 · The instantaneous output power of two-stage single-phase inverter pulsates at twice the output frequency, generating the second harmonic current (SHC) in the front-end DC

IDEALPLUSING | Principle of high frequency inverter rear stage

Principle of the circuit diagram of the rear stage of the high-frequency inverter. The basic function of the rear stage circuit is to invert the high-voltage DC boosted by the front stage into AC.

Research on Two-stage Isolated AC DC Converter with

Mar 14, 2024 · Abstract AC–DC converter has the advantages of high power density, stable output, easy to control, etc., and is widely used in many industrial fields. In this paper, the two

A new fast PWM modulation strategy for power electric

Oct 1, 2023 · The front stage of the two-stage photovoltaic inverter adopts boost switching converter to realize maximum power tracking. The rear stage realizes sine wave current

Inverter/PFC Converter Topology -Overview

Aug 19, 2025 · Multilevel topologies in PFC/Inverter Stage Three level topologies keep the switching voltage to half of a 2-level converter which improves overall EMI Multilevel topology

The Latest Innovations in Solar Inverter Technology

Jan 21, 2025 · Explore the exciting innovations in solar inverter technology, from AI-powered performance optimization and advanced battery storage to improved efficiency and smart

The inverter stage process of power inverter

The inverter stage of the Power Inverter is a key step in converting rectified DC power into AC power. This stage achieves precise control of the output waveform by using high-frequency

6 FAQs about [AC inverter front and rear stages]

What is a front stage AC/DC converter?

The front stage of the AC/DC converter is a power factor correction circuit, which can improve the power factor and reduce grid-side current harmonics. Its performance affects the utilization of grid energy and control effect of the rear-stage DC/DC converter. Current research on PFC circuits mainly focuses on Boost and its improved circuits.

What is a two-stage AC/DC converter?

With the continued development of the new energy vehicle industry, two-stage isolated AC/DC converters are widely used because of their simple topology and easy control characteristics. In this study, we investigate the front-stage Buck power factor correction (PFC) converter and rear-stage full-bridge converter.

What is the control strategy of two-stage AC/DC converter?

In summary, Cf = 100μF. The two-stage AC/DC converter control strategy is illustrated in ( Fig 6 ). Fig 6. Control strategy of two-stage AC/DC converter. The front-stage PFC circuit adopts a PI double-closed-loop control strategy [ 23 ]. The output voltage, input voltage, and input current were collected as the control variables.

Are there competing interests in AC/DC converter?

Competing interests: The authors have declared that no competing interests exist. With the development of power electronics technology, high efficiency, high power density, and wide voltage range of AC/DC converter using two-stage circuit structure have become the industry research hotspot.

What is a three-phase inverter reference design?

Three-phase inverter reference design for 200-480VAC drives (Rev. A) This reference design realizes a reinforced isolated three-phase inverter subsystem using isolated IGBT gate drivers and isolated current/voltage sensors.

What is the output of an inverter control MCU?

The output of an inverter control MCU is 3.3-V PWM signal. This has to be converted into a 10-mA current signal. Multiple circuit configurations can be implemented for this conversion. TIDA-010025 has provisions on board to evaluate each of the input drive methods.

Learn More

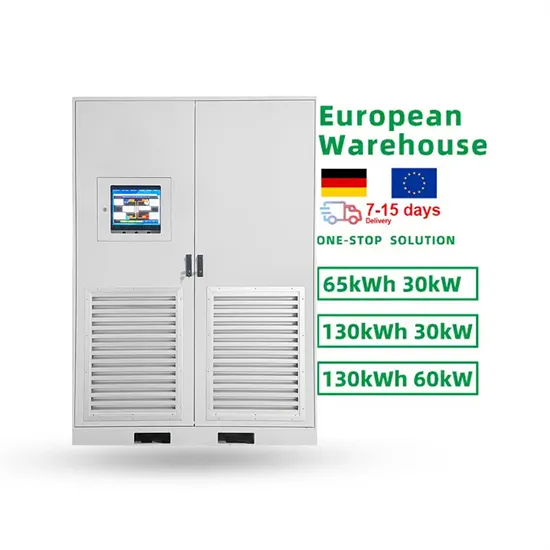

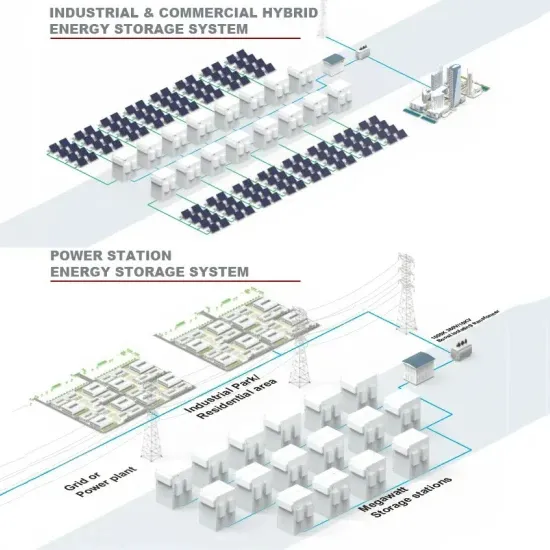

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

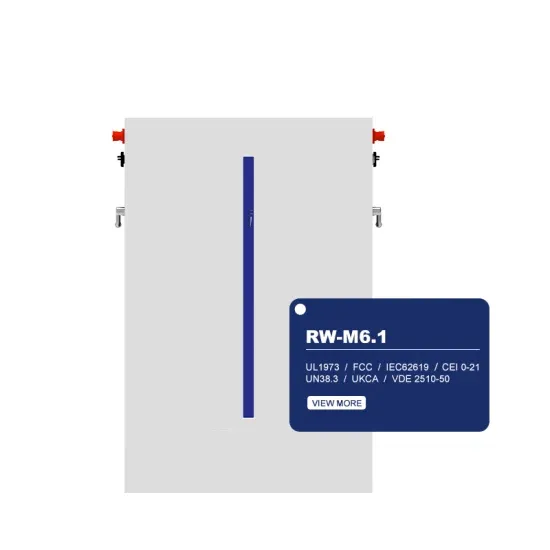

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.