What are the design materials for container energy storage

Discover the top 8 functional design considerations for Battery Energy Storage System (BESS) container enclosures, focusing on safety, durability, thermal control, and ease

Review of common hydrogen storage tanks and current

Mar 1, 2024 · The common methods to store hydrogen on-board include the liquid form storage, the compressed gas storage, and the material-based storage, and the working principles and

Containers for Thermal Energy Storage | SpringerLink

Feb 11, 2022 · The present work deals with the review of containers used for the phase change materials for different applications, namely, thermal energy storage, electronic cooling, food

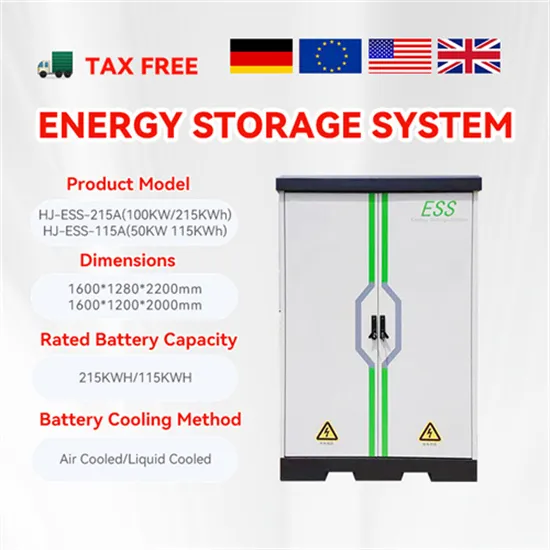

Energy storage container

Mar 1, 2021 · Electronic and atomic structure, microstructure, chemical and mechanical stability, electronic and ionic conductivity, as well as reactivity are examples of important parameters

Dimensional design of energy storage containers in

Hence,design engineers are looking for new materials for efficient ESS,and materials scientists have been studying advanced energy materials,employing transition metals and carbonaceous

Development of a new design for cold energy storage using

Jun 18, 2025 · Geometry modification of a vertical shell-and-tube latent heat thermal energy storage system using a framed structure with different undulated shapes for the phase change

Thermal Design of Energy Storage Containers: Balancing

Mar 4, 2021 · Turns out, energy storage containers share that pain. The thermal design of energy storage containers is the unsung hero keeping lithium-ion batteries from throwing tantrums (or

Container Energy Storage Systems : Structural & Door Design

Aug 17, 2025 · Designs should comply with ISO container standards (such as 20-foot or 40-foot containers) or custom specifications to ensure ease of transportation and storage. The design

Key Design Considerations for Energy Storage Containers

Apr 11, 2025 · The design of energy storage containers involves an integrated approach across material selection, structural integrity, and comprehensive safety measures. Choosing the right

Containerized Energy Storage System: How it

Jul 12, 2023 · A Containerized Energy-Storage System, or CESS, is an innovative energy storage solution packaged within a modular, transportable container. It

Energy Storage Container Design Information List: Key

Jul 20, 2021 · This article breaks down the energy storage container design information list into bite-sized pieces—perfect for engineers, project managers, and clean energy nerds who want

How are energy storage containers produced? | NenPower

Mar 6, 2024 · 1. Energy storage containers are produced through a systematic approach that incorporates several stages:1) Design specifications, 2) Material selection, 3) Manufacturing

Key Fire Safety Strategies and Design Elements for Energy Storage

Feb 8, 2025 · As energy storage systems (ESS) continue to play a crucial role in modern power grids, ensuring their safety—especially in terms of fire prevention is paramount. Battery Energy

Essential Design Features for a High-Performance BESS Container

Nov 27, 2024 · By addressing these eight essential design features, a BESS container enclosure can deliver unparalleled performance, reliability, and safety, making it a cornerstone of energy

6 FAQs about [What are the design materials for energy storage containers ]

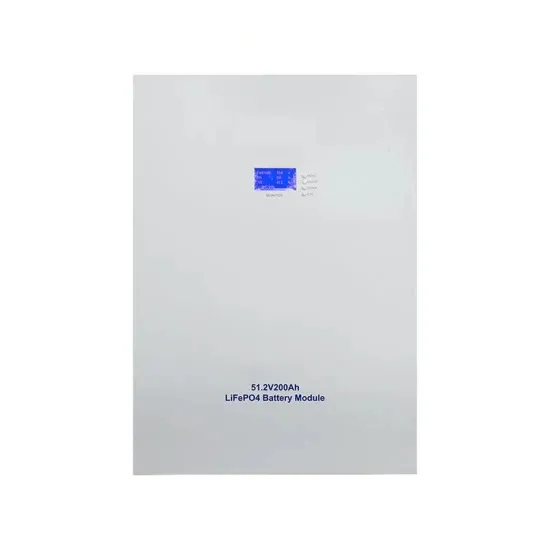

What materials can be used to develop efficient energy storage (ESS)?

Hence, design engineers are looking for new materials for efficient ESS, and materials scientists have been studying advanced energy materials, employing transition metals and carbonaceous 2D materials, that may be used to develop ESS.

How to design high-performing energy storage and conversion systems?

In principle, all these parameters can be characterized by applying experimental and/or theoretical techniques. Thus, designing high-performing energy storage and conversion systems requires combined theoretical/experimental efforts to screen materials in the search for optimal components.

Why are electrochemical energy storage systems important?

Electrochemical energy storage systems are crucial because they offer high energy density, quick response times, and scalability, making them ideal for integrating renewable energy sources like solar and wind into the grid.

Why do scientists want to develop more efficient energy storage systems?

Hence, Scientists are striving for new materials and technologies to develop more efficient ESS. Among energy storage technologies, batteries, and supercapacitors have received special attention as the leading electrochemical ESD. This is due to being the most feasible, environmentally friendly, and sustainable energy storage system.

Which energy storage technology is most efficient?

Among these various energy storage technologies, EES and HES are considered the most efficient and popular due to several key advantages including high energy density, efficiency, scalability, rapid response, and flexible applications.

What are architectured and functionalized materials?

To meet the needs of design Engineers for efficient energy storage devices, architectured and functionalized materials have become a key focus of current research. Functionalization and modification of the internal structure of materials are key design strategies to develop an efficient material with desired properties.

Learn More

- What are the design options for energy storage systems

- What are the working modes of energy storage containers

- What are the characteristics of special energy storage containers

- What are the regulations for the size of energy storage battery containers

- What is the function of the three energy storage containers

- What are the small energy storage outdoor power supplies

- What products are energy storage battery cabinets used for

- What are the capacitor energy storage systems in Libya

- What is the price of large energy storage cabinet factory in Nigeria

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.