Flywheel Energy Storage Rookie "Candla New Energy"

Aug 19, 2025 · The complete industry chain of flywheel energy storage products from production to mass production has the engineering ability to deliver flywheel energy storage systems in

Flywheel Energy Storage Housing | SpringerLink

May 4, 2023 · The housing of a flywheel energy storage system (FESS) also serves as a burst containment in the case of rotor failure of vehicle crash. In this chapter, the requirements for

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

Flywheel energy storage

Oct 28, 2015 · Flywheel energy storage (FES) works by accelerating a rotor (flywheel) to a very high speed and maintaining the energy in the system as rotational energy. When energy is

Grid-Scale Flywheel Energy Storage Plant

Dec 7, 2012 · Flywheel systems are kinetic energy storage devices that react instantly when needed. By accelerating a cylindrical rotor (flywheel) to a very high speed and maintaining the

How Flywheel Energy Storage is Stabilizing

Sep 19, 2024 · Flywheel energy storage systems have recently been found to be one of the firmest and most reliable solutions to stabilize power grids, primarily

Flywheel Energy Storage (FES): Exploring Alternative Use

May 4, 2017 · Flywheel Energy Storage (FES): Exploring Alternative Use Cases Randy Frank, Mechanical Engineering ''17 Jessica Matthys, Mechanical Engineering ''17 Caroline Ayanian,

Exploring Flywheel Energy Storage Systems and

Aug 18, 2025 · Overall, the operating principles of flywheel technology underscore its potential as a robust energy solution. By mastering kinetic energy storage,

Flywheel Energy Storage Market Size to Worth

Jul 2, 2025 · The global flywheel energy storage market size was valued at USD 1.43 billion in 2024 and is projected to worth around USD 1.81 billion by 2034

ADVANTAGES AND DISADVANTAGES OF FLYWHEEL

To use flywheel technology as an electrical energy storage medium offers several advantages and disadvantages compared to the other energy storage technologies. These are summarized in

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power

Supersystem of Mobile Flywheel Energy Storage | SpringerLink

May 4, 2023 · The supersystem of the flywheel energy storage system (FESS) comprises all aspects and components, which are outside the energy storage system itself, but which

Global Flywheel Energy Storage Systems Market Size,

Mar 28, 2025 · This report aims to provide a comprehensive presentation of the global market for Flywheel Energy Storage Systems, with both quantitative and qualitative analysis, to help

Flywheel Energy Storage Systems Market Size & Forecast 2033

2 days ago · Flywheel Energy Storage Systems Market Size, Share, Growth, and Industry Analysis, By Type (Metal Material Flywheel and Composite Flywheel), By Application (UPS

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · In this paper, state-of-the-art and future opportunities for flywheel energy storage systems are reviewed. The FESS technology is an interdisciplinary, complex subject that

Flywheel Energy Storage in China: Current Trends and Future

Mar 6, 2025 · If you''re curious about cutting-edge energy storage solutions in China, you''ve probably heard whispers about flywheel energy storage. This article is for engineers, investors,

6 FAQs about [Flywheel Energy Storage Customers]

Are flywheel energy storage systems a good choice?

Li-ion and lead-acid batteries are the most commonly used energy storage systems here. However, advantages of flywheel energy storage systems such as higher efficiency and longer life are projected to increase the demand for flywheel energy storage systems, within the country.

What is the cost of Flywheel storage?

The cost of a 25-kWh Flywheel storage system ranges from $4,,015 to $7,,400. The cost of battery storage is from $3,,972 to $8,,700. The efficiency of a Flywheel system is 73 percent compared with 65 percent for a battery system.

What are flywheels used for?

Flywheels are used as intermediate energy storage systems for transport applications such as automobiles. Flywheel storage energy systems are more commonly used in Formula 1 cars and hybrid vehicles. However, manufacturers such as Maruti Suzuki have adopted this technology for passenger vehicles also.

How much energy does a flywheel store?

It would probably have to be in a cement enclosure, and in Florida a sump pump to keep it dry. A 1,000kg, 5m, 200RPM flywheel would store 685,567J of energy if it was shaped like a disc. That's 0.19kWh of energy — enough to boil the water for about seven (7) cups of tea or run a typical airconditioner for about 10 minutes.

Does national highways have a flywheel energy storage system?

National Highways is partnering with Levistor to test our Flywheel Energy Storage System (FESS) alongside batteries and solar installations. We’re pleased to be working with Ansys and benefitting from their Startup Programme.

Can flywheels save energy?

Installing 100 MW’s worth of flywheels used for distribution can reduce demand charges by $36 million and provide $8 million of energy savings a year since the FESS can eliminate mid-day peak and evening peaks of electricity use. Lithium battery technology can only do one peak reduction a day.

Learn More

- Supercapacitor flywheel energy storage

- Storage time of flywheel energy storage

- Guatemala communication base station flywheel energy storage photovoltaic power generation capacity

- Irish Micro-Controlled Flywheel Energy Storage Company

- Flywheel energy storage application areas

- Castries Flywheel Energy Storage

- Flywheel energy storage 250kva

- Flywheel energy storage disc material

- One has several communication base stations with flywheel energy storage

Industrial & Commercial Energy Storage Market Growth

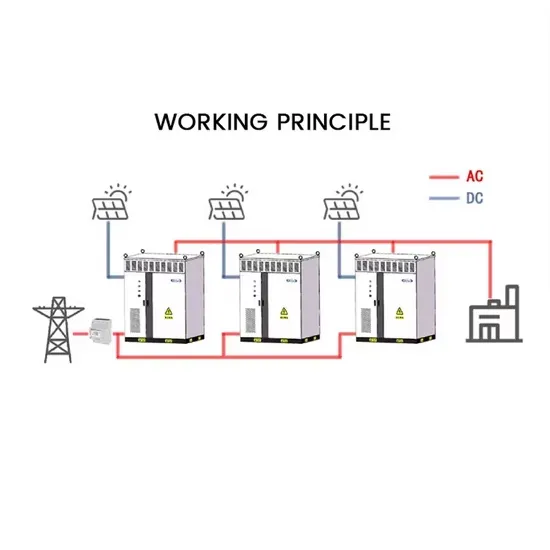

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.