Peak-shaving cost of power system in the key scenarios of

Jun 30, 2024 · Highlights • Driven by the peak and valley arbitrage profit, the energy storage power stations discharge during the peak load period and charge during the low load period. •

Scheduling Strategy of Energy Storage Peak-Shaving and Valley-Filling

Dec 20, 2021 · In order to make the energy storage system achieve the expected peak-shaving and valley-filling effect, an energy-storage peak-shaving scheduling strategy consi

Peak shaving benefit assessment considering the joint operation

Jan 15, 2022 · The rapid development of battery energy storage technology provides a potential way to solve the grid stability problem caused by the large-scale construction of nuclear

Multi-objective optimization of capacity and technology

Feb 1, 2024 · The model aims to minimize the load peak-to-valley difference after peak-shaving and valley-filling. We consider six existing mainstream energy storage technologies: pumped

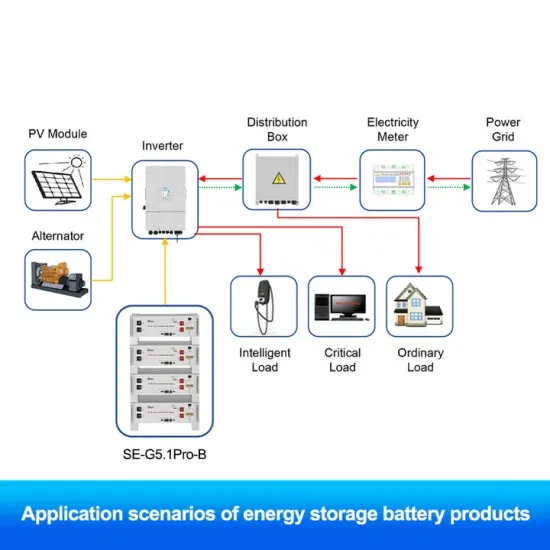

Peak shaving and valley filling energy storage

Peak shaving and valley filling energy storage Peak Shaving. Sometimes called "load shedding," peak shaving is a strategy for avoiding peak demand charges by quickly reducing power

Operation scheduling strategy of battery energy storage

Dec 25, 2023 · The battery energy storage system (BESS) as a flexible resource can effectively achieve peak shaving and valley filling for the daily load power curve. However, the different

Research on an optimal allocation method of energy storage

Jun 1, 2024 · Energy storage system (ESS) has the function of time-space transfer of energy and can be used for peak-shaving and valley-filling. Therefore, an optimal allocation method of

Peak shaving and valley filling energy storage project

Aug 15, 2025 · Store electricity during the "valley" period of electricity and discharge it during the "peak" period of electricity. In this way, the power peak load can be cut and the valley can be

Research on modeling and control strategy of lithium battery energy

Jun 1, 2023 · In this paper, we propose an improved control strategy considering peak-shaving and valley-filling as an effect for two-stage energy storage system, which includes multi

Peak-valley lithium battery energy storage

Abstract: From the power supply demand of the rural power grid nowadays, considering the current trend of large-scale application of clean energy, the peak shaving strategy of the

Peak shaving and valley filling potential of energy management system

Feb 1, 2019 · In this paper, a Multi-Agent System (MAS) framework is employed to investigate the peak shaving and valley filling potential of EMS in a HRB which is equipped with PV storage

Dynamic economic evaluation of hundred megawatt-scale

Oct 9, 2023 · With the rapid development of wind power, the pressure on peak regulation of the power grid is increased. Electrochemical energy storage is used on a large scale because of

Industrial and commercial energy storage: Peak shaving and valley

Industrial and commercial energy storage: Peak shaving and valley filling, helping enterprises save energy and reduce consumption With the increasing complexity of the power system and

Control strategy for peak shaving and valley

Nov 14, 2023 · Due to the fast charging and discharging characteristics of battery energy storage system, it is charged during low load periods and discharged

A comparison of optimal peak clipping and load shifting energy storage

Jul 1, 2023 · Variation in ∊ for different energy storage capacities and discharge times (DTs) of a Li-ion battery energy storage system under both peak clipping and load shifting control

What is Peak Shaving and Valley Filling?

Apr 26, 2024 · In today''s energy-driven world, effective management of electricity consumption is paramount. Two strategic approaches, peak shaving and valley filling, are at the forefront of

Smart Grid Peak Shaving with Energy Storage: Integrated

The optimized energy storage system stabilizes the daily load curve at 800 kW, reduces the peak-valley difference by 62%, and decreases grid regulation pressure by 58.3%. This research

基于SOC的储能削峰填谷控制策略

MORE Aiming at the problem of peak shaving and valley filling,this paper takes 24 hours a day as a cycle,on the premise that the initial state of the energy storage system remains

Impact Analysis of Energy Storage Participating in Peak Shaving

Result Through simulation calculations, the influence trend of energy storage participating in peak shaving and valley filling for the distribution network on network loss power and voltage loss is

(PDF) Research on an optimal allocation method of energy storage

Jun 1, 2024 · Energy storage system (ESS) has the function of time-space transfer of energy and can be used for peak-shaving and valley-filling.

Peak Shaving and Valley Filling with Energy Storage Systems

Aug 18, 2025 · Peak shaving and valley filling refer to energy management strategies that balance electricity supply and demand by storing energy during periods of low demand (valley) and

How does the energy storage system reduce peak loads and fill

Oct 21, 2024 · Peak Management in Grid-Connected Microgrid Combining Battery Storage This study focused on an improved decision tree-based algorithm to cover off-peak hours and

Hitek 40FT 500kw 2MW 2150kwh Bess Solar Power System Peak Shaving

Jul 27, 2025 · Hitek 40FT 500kw 2MW 2150kwh Bess Solar Power System Peak Shaving and Valley Filling Outdoor Battery Storage Container US$0.88 500,000-999,999 Watt

6 FAQs about [Peak shaving and valley filling energy storage lithium battery]

What is peak shaving in battery energy storage?

A Battery Energy Storage System (BESS) is an effective way to shave the peaks and to smooth the load during energy production changes with dynamic power demand. This paper introduces a novel peak shaving method with a PV-battery storage system. The method is tested on a system in U1m, Germany.

Should energy storage system be used for peak shaving?

An energy storage system (ESS) application is more advantageous than the demand response program, where it allows customers to simultaneously shave peak load and perform daily activities as usual. Therefore, future research should emphasise on the proper application of DSM with ESS system for peak shaving purpose. 6.

Are on-site batteries better than peak shaving?

Peak shaving with batteries is better than on-site batteries alone. While all electrons are essentially the same, with peak shaving, you’re only paying for the absolute cheapest ones. This helps you level out the peaks and valleys in your energy spending to ensure you’re saving as much money as possible. Additionally, peak shaving with batteries isn’t something you must actively manage.

Can PEV batteries be used for peak shaving?

Alam et al. proposed an effective strategy to utilise PEV batteries for both travelling and peak shaving purpose. A dynamic discharge rate was implemented to ensure the best use of PEV batteries for peak shaving. Finally, the proposed strategy was tested with practical PEV data in Australia.

Do energy storage systems achieve the expected peak-shaving and valley-filling effect?

Abstract: In order to make the energy storage system achieve the expected peak-shaving and valley-filling effect, an energy-storage peak-shaving scheduling strategy considering the improvement goal of peak-valley difference is proposed.

Does constant power control improve peak shaving and valley filling?

Finally, taking the actual load data of a certain area as an example, the advantages and disadvantages of this strategy and the constant power control strategy are compared through simulation, and it is verified that this strategy has a better effect of peak shaving and valley filling. Conferences > 2021 11th International Confe...

Learn More

- Peak shaving and valley filling energy storage microgrid

- Energy storage battery peak and valley at home

- Basseterre energy storage lithium battery manufacturer

- Outdoor lithium battery energy storage cabinet quotation

- Huawei Helsinki Energy Storage Lithium Battery

- Japan Osaka Energy Storage Lithium Battery Wholesale

- Lithium battery cost for container energy storage system

- Banjul lithium battery hybrid energy storage project

- Swiss Photovoltaic Energy Storage Cabinet Battery Lithium Battery

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.