Effective Grounding of Photovoltaic Inverters

Aug 2, 2019 · Abstract Effective grounding has historically been defined in the IEEE Green Book as it relates to the positive-sequence reactance relative to the zero-sequence reactance. This

Part 1: Commercial PV System Sizing and Design

Aug 8, 2018 · First, SMA''s free sizing and simulation tool, Sunny Design, allows you to size systems correctly by matching SMA inverters with PV curves, and

DC/AC ratio: How to choose the right size solar

Apr 19, 2022 · We''ll use RatedPower software to debrief how to get the optimal DC/AC ratio based on your design. Iterate your DC/AC ratio at scale You can

DC/AC inverter oversizing ratio – what is the optimal

Mar 2, 2021 · DC/AC ratio The ratio of the DC output power of a PV array to the total inverter AC output capacity. For example, a solar PV array of 13 MW combined STC output power

How many inverters are needed for photovoltaic power

Installers typically follow one of three common solar inverter sizing ratios: For our example 7 KW system,this translates to inverter sizes between 8,750 watts and 9,450 watts. While the above

Renewables Insights: The Impact of Solar Photovoltaics

The Impact of Solar Photovoltaics (PV) DC:AC Ratio In recent years, solar project developers have continued to increase the dc:ac ratio1 (also known as inverter loading ratio) of their PV

Technical Note: Oversizing of SolarEdge Inverters

Oct 30, 2023 · However, too much oversizing of the inverter may have a negative impact on the total energy produced and on the inverter lifetime. This document provides information for

DC/AC inverter oversizing ratio what is the optimal ratio

Mar 2, 2021 · Oversizing inverters (that is systems with a DC/AC ratio >1.00) is common practice in both Australia and worldwide, as solar PV modules rarely operate at their STC performance

What are the ratios of photovoltaic inverters

A healthy design will typically have a DC/AC ratio of 1.25. What is a good DC/AC ratio for a PV system? A 1:0.8ratio (or 1.25 ratio) is the sweet spot for minimizing potential losses and

How many inverters are needed for photovoltaic power

Estimates the size of the inverter needed for a PV system. I = P / V: I = Inverter size (kVA), P = Peak power from the PV array (kW), V = Voltage (V) Cable Size: Determines the suitable size

Optimal sizing of array and inverter for grid-connected photovoltaic

Dec 1, 2006 · Optimum PV/inverter sizing ratios for grid-connected PV systems in selected European locations were determined in terms of total system output, system

How to choose the ratio of photovoltaic inverters and

Jul 28, 2022 · In fact, the ratio between photovoltaic modules and inverters needs to comprehensively consider a variety of factors, such as light conditions, installation site,

Impact of inverter DC to AC ratio on soiling losses and

Väisänen et al. [24] encourage the adoption of residential PV systems in Finland, inverters can be undersized to reduce investment costs, potentially covering 15 %–27 % of the costs of a new

The ratio of photovoltaic modules and inverters in terms of

The ratio of photovoltaic module capacity to inverter capacity is usually called capacity ratio. Reasonable capacity ratio design needs to be considered comprehensively in combination

6 FAQs about [What are the ratios of photovoltaic inverters ]

What is a good DC/AC ratio for a solar inverter?

If a PV array has a rated DC capacity of 12kW and the inverter has an AC rated output of 10kW, the DC/AC ratio would be 1.2. What Is the Ideal DC/AC Ratio? In most cases, the ideal DC/AC ratio typically ranges between 1.2 and 1.4. However, the optimal value can vary based on local climate conditions, equipment costs, and specific project goals.

What is the DC/AC ratio of a PV array?

DC/AC Ratio= PV Array’s DC Power (kW) / Inverter’s AC Power (kW) If a PV array has a rated DC capacity of 12kW and the inverter has an AC rated output of 10kW, the DC/AC ratio would be 1.2. What Is the Ideal DC/AC Ratio? In most cases, the ideal DC/AC ratio typically ranges between 1.2 and 1.4.

How do I choose the right solar inverter?

Selecting the right solar inverter for your project involves understanding the DC-to-AC ratio and its impact on your system’s efficiency. This article explores the significance of the DC-to-AC ratio, how it affects energy production, and tips to optimize your solar installation. Understanding the DC-to-AC Ratio

Should a 9 kW PV array be paired with an AC inverter?

Thus a 9 kW PV array paired with a 7.6 kW AC inverter would have an ideal DC/AC ratio with minimal power loss. When the DC/AC ratio of a solar system is too high, the likelihood of the PV array producing more power than the inverter can handle is increases.

What is DC/AC ratio?

The DC/AC ratio, also known as the DC to AC ratio, refers to the ratio between the direct current (DC) rated power of a photovoltaic (PV) array and the alternating current (AC) rated output of an inverter. DC/AC Ratio= PV Array’s DC Power (kW) / Inverter’s AC Power (kW)

What happens if a PV inverter loses power?

In the event that the PV array outputs more energy than the inverter can handle, the inverter will reduce the voltage of the electricity and drop the power output. This loss in power is known as “clipping”. For example, a DC/AC ratio of 1.5 will likely see clipping losses of 2-5%. Not as major as other losses, but still a noticeable effect.

Learn More

- What brands of off-grid photovoltaic inverters are there

- What is the difference between the size of photovoltaic inverters

- What does wind power and photovoltaic power generation include in Antananarivo communication base station

- Do photovoltaic inverters need regular maintenance

- What are the types of photovoltaic energy storage projects

- What is the infrastructure of photovoltaic energy storage equipment

- Individuals can produce photovoltaic inverters

- What is the use of battery optimization in photovoltaic container systems

- Photovoltaic grid-connected cabinets and inverters

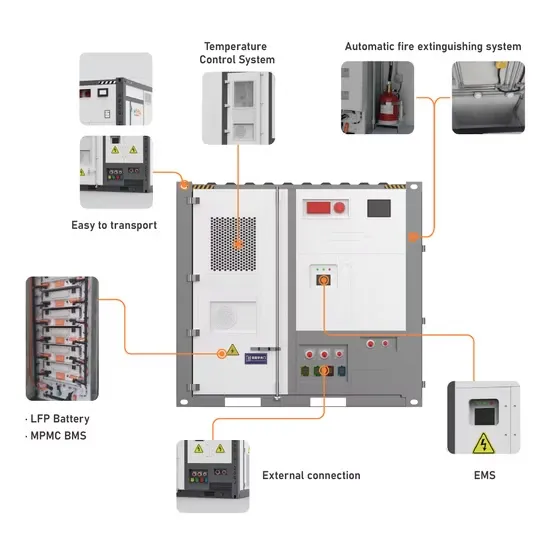

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

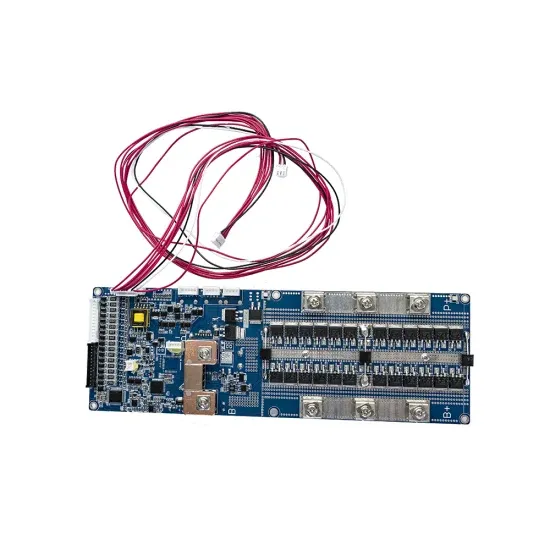

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.