Thermal runaway behaviour and heat generation

Mar 1, 2024 · The findings of this study provide insights into the TR behaviour of a marine battery cabinet and its influence on heat generation as well as guidance for the thermal management

Battery Cooling Methods in Electric Cars_XNmotors

2 days ago · Conclusion The battery cooling method is a key factor in ensuring the smooth, safe, and efficient operation of an electric car. As technology evolves, automakers continue to refine

Advances in direct cooling battery thermal management

Aug 8, 2024 · This review starts with a brief overview of the factors contributing to battery heat generation. It then delves into direct cooling battery thermal management technology, which

Structural Design of the Refrigerant Direct Cooling

Apr 18, 2025 · Refrigerant direct cooling uses refrigerants as cooling media, combining the char-acteristics of indirect contact liquid cooling and traditional air conditioning systems. By

Exploring Liquid Cooling Battery Cabinet Technology

Innovations in Battery Cabinet Cooling Technology The sophistication of modern Battery Cabinet Cooling Technology is a testament to precision engineering. These are not simply add-on

Study on battery direct-cooling coupled with air conditioner

Oct 15, 2023 · Zhang et al. proposed a method to control the temperature of sizeable soft pack batteries using a liquid cooling plate with streamlined channels, analyzed the effects of mass

Principle of new energy liquid cooling battery cabinet

This paper presents a novel cooling structure for cylindrical power batteries, which cools the battery with heat pipes and uses liquid cooling to dissipate heat from the heat pipes.

Introduction to the principle of direct cooling technology for batteries

Battery Cooling System in Electric Vehicle: Techniques and This need for direct cooling arises due to the significant heat generated by the high current flowing into the battery during fast

Immersion cooling technology development status of

At the same time, the utilization of waste heat in the data center immersion cooling system is discussed, providing readers with extensive and detailed background knowledge of data

Thermal performance of direct two-phase refrigerant cooling for lithium

Jun 5, 2020 · An efficient battery thermal management system is essential for lithium-ion batteries with high cooling performance and long lifetime. The objective of this study is to investigate the

Electric Vehicle Battery Cooling Methods Are

Mar 15, 2023 · A liquid coolant such as water, a refrigerant, or ethylene glycol—a type of liquid coolant also found in antifreeze—is used for the purpose of

Liquid Cooling Battery Cabinet: Maximize Efficiency Now

Excessive heat can significantly degrade battery health, reduce efficiency, and pose serious safety risks. To address this, the industry is increasingly turning to advanced solutions like the

New energy battery cabinet fan cooling principle

How to improve battery cooling efficiency? Some new cooling technologies,such as microchannel cooling,have been introduced into battery systems to improve cooling efficiency. Intelligent

Battery cabinet cooling system working principle

The efficient control and regulation of cooling mechanisms and temperature are of utmost importance to uphold battery performance, prolong battery lifespan, and guarantee the safe

Research progress on power battery cooling technology for

Feb 1, 2020 · In this context, several battery thermal management systems (BTMS) are reviewed, including air cooling BTMS, liquid cooling BTMS and refrigerant direct cooling BTMS in

Application of Refrigerant Cooling in a Battery

Jun 5, 2024 · Battery thermal management (BTM) is crucial for the lifespan and safety of batteries. Refrigerant cooling is a novel cooling technique that is

Comparison of cooling methods for lithium ion

Dec 13, 2023 · Comparison of cooling methods for lithium ion battery pack heat dissipation: air cooling vs. liquid cooling vs. phase change material cooling vs.

Next-Gen Battery Cooling: Using AI, New Tech, and

Mar 21, 2025 · Battery Thermal Management Systems (BTMS) play a pivotal role in maintaining safe and optimal operating temperatures within lithium-ion batteries. Without effective thermal

Study on battery direct-cooling coupled with air conditioner

Oct 15, 2023 · The results show that for both battery and cabin, the Estimation-feedback control method has a good temperature control performance and ensures good energy

6 FAQs about [Battery cabinet direct cooling and heating technology principle]

How does a direct-cooling battery thermal management system work?

In vehicles, the direct-cooling battery thermal management system usually connects the battery cooling plates parallel to the vehicle air conditioning evaporator, forming a cooling system with two evaporators with different cooling requirements.

Can a refrigerant-based battery thermal management system be used for electric vehicles?

A novel electric vehicle thermal management system based on cooling and heating of batteries by refrigerant Energy Convers. Manag., 237 ( 2021), Article 114145 System simulation on refrigerant-based battery thermal management technology for electric vehicles Energy Convers. Manag., 203 ( 2020), Article 112176 J. Electrochem.

Why is air-cooling battery thermal management system bad?

Because of the miniature thermal conductivity of air, the air-cooling battery thermal management system has low heat transfer efficiency and insufficient cooling capacity, so it cannot meet the cooling requirements of the battery when the battery is operating at high power.

What is integrated battery thermal management system (BTM)?

Integrated Battery Thermal Management System Coupling Phase Change Material Cooling and Direct Heating Strategies The current battery thermal management (BTM) system integrating indirect heating and PCM cooling structures still suffers from relatively low heating efficiency and high energy consumption.

How does battery cooling work?

Efficient cooling relies on a direct or indirect process. In a direct approach, liquid contact might touch battery cells. In an indirect format, thermal interfaces exist between cells and cooling plates. Both methods optimize temperature by moving heat into a fluid or air stream. That fluid then leaves the battery zone.

How do EV battery cooling systems work?

Common EV battery cooling methods are liquid cooling, air cooling, phase-change cooling, and refrigerant-based cooling. Liquid systems use fluids like water-glycol. Air cooling blows air across battery modules. Phase-change materials absorb excess heat. Refrigerant systems adapt HVAC technology to maintain stable cell temperatures.

Learn More

- Battery cabinet cooling system principle

- Explosion-proof battery cabinet manufacturer direct sales system

- Battery cabinet technology status and development

- Battery Cabinet Inverter Working Principle

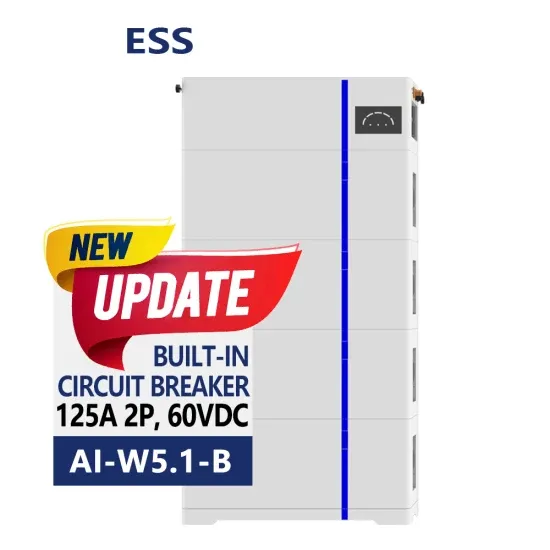

- Domestic energy storage battery cabinet photovoltaic technology

- Maximum heating power of battery cabinet

- Battery Cabinet Technology Competition

- Armenia exhibits battery cabinet technology

- Battery cabinet quick change technology equipment

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.