How to choose the perfect charge controller

Sep 16, 2014 · In this case, it would be the 80 amp controller. Now if you know the amperage of the controller, and you would like to figure out how the maximum solar array wattage that can

How to Calculate Solar Panels Needed to Charge Batteries: A

Nov 15, 2024 · Unlock the potential of solar energy with our comprehensive guide on calculating the number of solar panels needed to charge batteries. Understand key factors such as daily

How To Calculate Solar Panel Battery And Inverter Size

6 days ago · So the battery you need, must be of 3456Wh * 2 * 2 = 13824Wh or above. Keeping it simple, you need batteries with total 14kWh capacity. To convert it to Ah capacity, we have to

Solar Panel Amps Calculator (Watts to Amps) – Dot Watts®

Nov 17, 2023 · Both lead-acid and lithium deep cycle batteries may be charged with a 50-watt solar panel. There are a few ways in which they differ from the

How many A is a solar panel? | NenPower

Aug 24, 2024 · A solar panel typically operates at various electrical currents, usually measured in amperes (A), depending on its design and efficiency. Here are the key points: 1. The current

How many amperes of battery should be used with

In general, normal solar panel has 18V panel rated with 12V battery system take sunlight up to 6 hours daily then it would produce amps listed below for watts range for 50-400. What Is the

Is 40 amp Charge Controller okay for 500 watts solar?

Apr 7, 2021 · But I want to get two 250 watt panels on my camper van. Do I need to get a 50 amp or bigger charge controller? Or can I stick with the 40 amp that he shows in the video? I''ve

Solar Panel To Battery Ratio (Kw + Watts)

Sep 9, 2022 · For example, if you have a 100-watt panel producing about 6 amps per hour, or 30aH per day, coupled with a 200aH battery, your battery will not be getting enough amps for

How many amperes should the photovoltaic panel

A 100-watt solar panel will produce 0.65 ampsof AC current in the US with 120 volts or 0.34 amps in places with 230 volts AC grid (like Europe). In addition,it will supply your 12-volt battery bank

How many amperes of battery can be charged

Oct 10, 2024 · The solar panel''s output is dictated by its wattage rating, generally ranging from 100 watts to 400 watts or more. For instance, a 200-watt panel

50 Watt Solar Panels Technical Specs & Installation

Jan 2, 2024 · With solar panels, the wattage rating indicates its maximum power output under standard test conditions. Therefore, a 50-watt solar panel

How many amperes of battery should be used with

In general, normal solar panel has 18V panel rated with 12V battery system take sunlight up to 6 hours daily then it would produce amps listed below for watts range for 50-400.

How many amperes of battery should be used with

This article explains the size of solar panels to charge a 12V battery, two methods to charge a 12V battery with solar panels, and how many solar panels are needed. In addition, Jackery Sizes

How many amperes of battery should be used with

How many watts a solar panel to charge a battery? You need around 360 wattsof solar panels to charge a 12V 100ah Lithium (LiFePO4) battery from 100% depth of discharge in 4 peak sun

How many amps of batteries are needed for a 50w solar light?

May 19, 2024 · To determine the required amperage of batteries for powering a 50W solar light, several factors must be considered. 1. The power consumption of the light, 2. The voltage of

6 FAQs about [How many amperes of battery should a 50 watt 6v solar panel be equipped with]

How many amps can a 600 watt solar panel store?

600-watt solar panel will store 50 amps in a 12v battery per hour. Solar Panel Calculator For Battery: What Size Solar Panel Do I Need? How Long To Charge 12v Battery With Solar panel?

How many batteries do you need for a 50 watt solar panel?

1,200 amp-hours / 100 amp-hours (per battery) = 1 (battery) Therefore, you would need one battery to store enough energy to power a 50-watt load for 24 hours. Do note that the example above is just a basic calculation based on the assumption that the solar panels run optimally.

How many amps does a solar panel store?

To calculate the amps from watts use this formula. 100-watt solar panel will store 8.3 amps in a 12v battery per hour. 300-watt solar panel will store 25 amps in a 12v battery per hour. 400-watt solar panel will store 33.3 amps in a 12v battery per hour. 500-watt solar panel will store 41.6 amps in a 12v battery per hour.

How much power does a 50 watt solar panel produce?

With solar panels, the wattage rating indicates its maximum power output under standard test conditions. Therefore, a 50-watt solar panel produces 50 watt-hours of electricity in one hour under optimal conditions. However, while a 50-watt solar panel can produce 50 watts per hour, real-life conditions will impact performance.

How many watts of battery do I Need?

Ideally, a battery bank of four 200ah batteries with 1kw of panels is best, or around 600ah of battery power. 2kw of panels (8x 250-watt panels, 6x 330 panels, 3x 615-watt panels), and up to ten 200ah batteries. 4kw of panels (12x 330-watt panels, 6x 615-watt panels), and 2,400ah of battery storage.

How much power does a 500 watt solar panel need?

Around 250ah of power, ideally a 200ah battery, or 2x120ah batteries. A 500-watt panel setup (2x 250-watt panels) can easily charge a 200ah battery in a day, so you could have 2x200ah batteries charging if you are not running them flat every day.

Learn More

- How much current does a 6v 6 watt solar panel have

- How big a battery should I use for 25 watt solar power

- How big a battery should I use for a 10 watt photovoltaic panel

- How big is a 1 watt solar panel

- How big a battery pack does a 100 watt LED solar street light require

- How big a battery should a 400w photovoltaic panel be equipped with

- How big is a 300 watt solar panel

- How big is the battery for a 10w photovoltaic solar panel

- 255 watt 18v solar panel

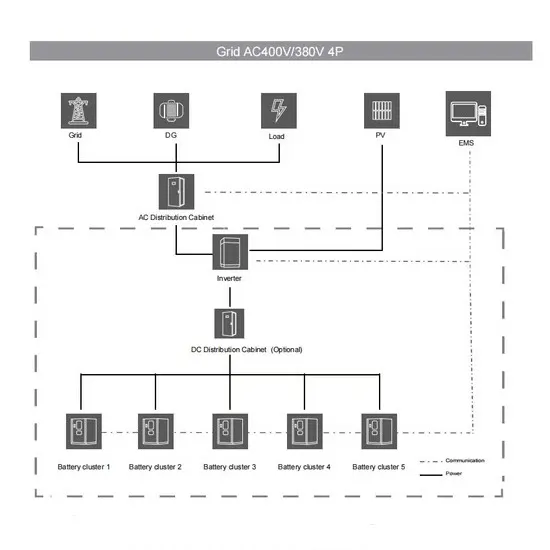

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.