An overview of solar photovoltaic panels'' end-of-life material

Jan 1, 2020 · End-of-life (EOL) solar panels may become a source of hazardous waste although there are enormous benefits globally from the growth in solar power gen

Methodological approaches for resource recovery from end-of-life panels

Jan 1, 2025 · Kavousi and Alamdari [68] present an alternative approach to recovery of valuable resource and toxic materials from the obsolete solar panels of different generations of PV.

A new method to extract the equivalent circuit parameters of

Mar 15, 2018 · This paper offers a new method to extract the equivalent circuit parameters of a single diode photovoltaic (PV) panel. These parameters were determined by using the

An experimental study on determination of optimal tilt and

Jul 22, 2024 · An experimental setup is established to measure solar radiation, power, and temperature data. The electrical energy, open-circuit voltage, and short-circuit current

(PDF) Photovoltaic panels tilt angle optimization

Jan 1, 2021 · The tilt angle of solar panels is significant for capturing solar radiation that reaches the surface of the panel. Photovoltaic (PV) performance

An optimization approach for sustainable and resilient

Feb 1, 2025 · The study presents a scenario-based robust optimization model for developing a sustainable and resilient closed-loop floating solar photovoltaic supply chain network design.

Solar photovoltaic panel production in Mexico: A novel

Apr 1, 2024 · Highlights • Mathematical model for the production of photovoltaic solar panels. • Total profits, water consumption, and emissions generated were considered. • A hybrid

Top 11 Solar Panel Manufacturers in China :

Nov 30, 2024 · In this article, we will explore the key manufacturing hubs that fuel China''s solar industry, highlight the top 11 solar panel manufacturers in China,

Innovative device for mechanical treatment of End of Life photovoltaic

Jul 15, 2019 · For solar modules, the regulation fixes collection rate up to 85% and recycling rate up to 80%. As European manufacturers and distributors are legally obliged to guarantee take

A review of solar photovoltaic technologies: developments,

Jul 1, 2025 · A historical perspective is provided, tracing PV technology from the discovery of the photovoltaic effect in 1839 to its latest innovations, such as high-efficiency cells, bifacial

Managing photovoltaic Waste: Sustainable solutions and

Nov 15, 2024 · The PV market is currently dominated by crystalline silicon (c-Si) PV panels, comprising approximately 97 % of total production in 2023 [2]. The majority of solar PV

Spatial layout optimization for solar photovoltaic (PV) panel

May 1, 2020 · How to make the best use of a solar photovoltaic (PV) system has received much attention in recent years. Integrating geographic information systems (GIS), this paper

A comprehensive review on the recycling technology of

Apr 5, 2024 · Recycling PV panels through e-waste management is crucial step in minimizing the environmental impact of end-of-life PV systems such as the release of heavy metals into the

Advancements In Photovoltaic (Pv) Technology for Solar

Jul 13, 2023 · Photovoltaic (PV) technologies, more commonly known as solar panels, generate power using devices that absorb energy from sunlight and convert it into electrical energy

A review of solar photovoltaic technologies: developments,

Jul 1, 2025 · Solar PV is considered one of the most decarbonized electricity generation systems, offering a promising solution to mitigate climate change and enhance energy security. By

Ecological and environmental effects of global photovoltaic

Jan 1, 2025 · Essentially, the installation of photovoltaic panels can impact surface water, heat exchange, and energy balance, leading to spatial and temporal variations in environmental

10 Best Solar Panel Manufacturers

Aug 15, 2024 · A solar panel manufacturer is an organization or business involved in the design, production, and often distribution of photovoltaic (PV) panels. These PV panels are

6 FAQs about [Photovoltaic panel manufacturers taking a different approach]

How do new solar panel manufacturing companies use solar energy?

New solar panel manufacturing companies utilize solar energy through the development of technologies such as building-integrated photovoltaics (BIPV). It integrates solar power into building materials. Likewise, the exploration of floating solar panels maximizes unused water bodies for energy production.

What are the latest trends in solar panel manufacturing?

Solar Panel Manufacturing Trends: A few latest trends in solar panel production are BIPV, floating solar, perovskite solar cells, graphene-based solar cells, and advanced thin-film technology. Solar Panel Industry Stats: The solar panel manufacturing sector has about 17K+ organizations, housing 1.3K+ organizations in the last 5 years.

How many new solar panel manufacturing companies are there?

Within the solar panel manufacturing industry, which emcompasses 17K+ companies, new solar panel manufacturing companies are marking significant advancements. Out of 1.3K+ new players, 10 trailblazers are making waves with innovations in building-integrated photovoltaics, floating solar panels, perovskite solar cell technologies, and more.

What makes China's solar panel manufacturing industry unique?

In conclusion, China’s solar panel manufacturing industry stands at the forefront of global renewable energy efforts, offering a vast array of high-quality products from leading manufacturers like Primroot.com, Jinko Solar, Trina Solar, and LONGi Green Energy.

Why is it important to understand the solar panel manufacturing process?

Understanding the solar panel manufacturing process is important. It helps people know how solar panels are made and why they are a good choice for energy. When consumers understand this process, they can make better decisions about using solar energy. Solar energy can save money and help the environment.

Why are PV panels becoming more popular in 2025?

In 2025, manufacturers are increasingly turning to cutting-edge materials like perovskite and tandem cells, which offer superior light absorption and energy conversion. 1. Higher efficiency translates to lower costs over time. 2. Enhanced performance makes home pv panels more viable for households. 3.

Learn More

- Good photovoltaic panel manufacturers in Windhoek

- Shading photovoltaic panel manufacturers

- Dhaka photovoltaic panel manufacturers

- Photovoltaic panel component manufacturers

- Honduras has photovoltaic panel manufacturers

- Smart photovoltaic panel equipment manufacturers

- There are photovoltaic panel manufacturers in Brussels

- South Sudan monocrystalline photovoltaic panel manufacturers supply

- Ottawa solar photovoltaic panel manufacturers

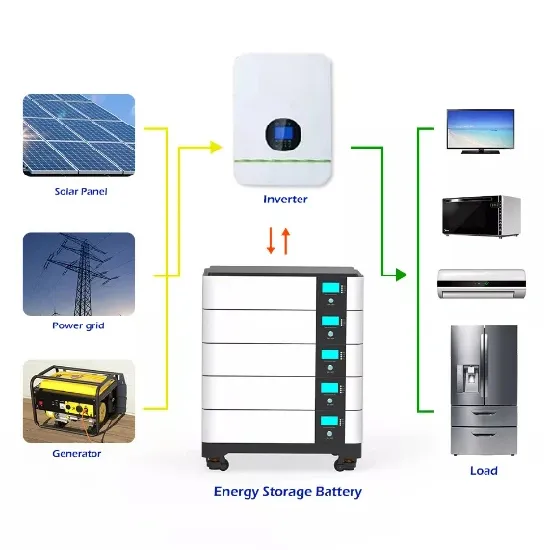

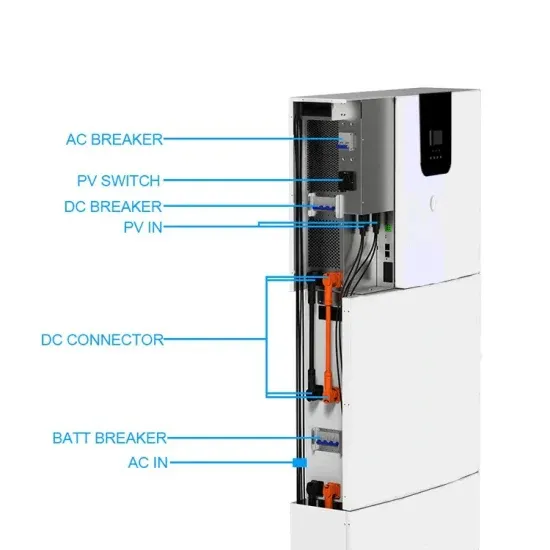

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.