DC battery cabinet grounding requirements and standards

UBC80 Battery Cabinet Installation, Operation, Minimum Size Conductor for Grounding the Battery Cabinet Battery Cabinet Breaker or Fuse Size Copper Wire Size Aluminum Wire Size

Grounded and ungrounded electrical and power system design

Jun 20, 2017 · A dc grounding electrode is required to bond the battery cabinet and other exposed metal parts between the battery and first disconnect. For a large-scale UPS, the default

Why Should Battery Racks Be Grounded? Safety and

Jun 15, 2025 · Battery racks should be grounded to prevent electrical hazards, reduce fire risks, and ensure compliance with safety standards like NEC Article 480 and NFPA 70. Grounding

Battery Cabinet Working Space Front Aisle Floor Loading

Direct-current ground-fault detection. Not all battery systems have DC ground-fault detection but many do. The ground-fault detection used must be based on the grounding methodology being

Do battery racks need to be grounded?

May 3, 2025 · What defines grounding requirements for battery racks? Metallic battery racks must comply with electrical safety codes (e.g., GB50169-2016) requiring direct earth connections.

How to Ground a Server Rack | Requirements of

Apr 29, 2023 · This text will cover network rack grounding, the stages of bonding, and the main requirements for how to ground a network rack. The Importance

Should Battery Racks Be Earthed? Safety and Compliance

Feb 22, 2025 · Earthing battery racks is critical for safety, preventing electric shocks, and mitigating fire risks. International standards like IEC 62485 and NFPA 855 mandate grounding

-48 VDC Battery Cabinet Installation and User Manual

Apr 21, 2022 · Install the frame ground landing point adapter P/N 556872 to the left or right side of the battery cabinet, as shown in Figure 5. Installing P/N 556872 Frame Ground Landing Point

NFPA 70 and NFPA 70E Battery-Related Codes Update

Jan 10, 2023 · Abstract Two code documents have a dramatic impact on the acceptance or rejection of a battery installation by an inspector. These are the National Electrical Code (NEC

DC System Grounds: Can You Afford to Live with Them?

Feb 28, 2024 · lished from one polarity of the dc system to ground. The stationary battery and dc bus link of an uninterruptible power supply (UPS) used in many mission critical applications

Earthing the battery cabinet

Jun 13, 2025 · Earth the battery management system during installation. Connect the supplied grounding cable to the battery cabinet grounding point (hexagon socket, AF13, torque: 8 Nm).

Principle Cabinet Design EMC and grounding G574e Part 3

Mar 22, 2024 · The PE busbar has to be fixed to the cabinet frame by screws to provide grounding The cross section of the grounding busbar or cable has to be at least half of the

What are the standard requirements for battery energy storage cabinets

Jun 2, 2024 · Battery energy storage cabinets must comply with several critical criteria: 1. Material durability, ensuring resilience against environmental factors, 2. Adequate thermal

Telecommunication Grounding & Bonding

May 31, 2018 · 4. Set up - Components of grounding & Bonding System ISO/IEC Referenced Note that on the ISO/IEC 30129 (released Oct 2015) Standard for Information Technology :

What are the standard requirements for battery energy storage cabinets

Jun 2, 2024 · 1. Battery energy storage cabinets must comply with several critical criteria: 1. Material durability, ensuring resilience against environmental factors, 2. Adequate thermal

What Are Battery Rack Cabinets and Why Are They Essential?

Jun 15, 2025 · Battery rack cabinets are modular enclosures designed to securely house and organize multiple batteries in industrial, telecom, or renewable energy systems. They optimize

6 FAQs about [What are the grounding requirements for DC battery cabinets ]

What are the safety requirements related to batteries & Battery rooms?

Employers must consider exposure to these hazards when developing safe work practices and selecting personal protective equipment (PPE). That is where Article 320, Safety Requirements Related to Batteries and Battery Rooms comes in.

Does DC traction power distribution equipment need grounding?

Abstract: The grounding of dc equipment enclosures installed in dc traction power distribution facilities as well as related insulation treatments required for solid and resistance grounding methods are covered in this standard.

Do you need documentation before entering a battery room?

It is a requirement to have all the documentation in place prior to authorized personnel entering a battery room to perform a specific work task on a battery system under normal operating conditions. However, it is likely the employee will need to enter the battery room to deal with a battery system that is not operating normally.

Is system grounding covered in this document?

System grounding, though related, is not covered in this document. Scope: This document includes recommended practices for grounding of dc equipment enclosures installed in dc traction power distribution facilities.

Is working on a battery considered energized electrical work?

Working on a battery should always considered energized electrical work. NFPA 70E ®, Standard for Electrical Safety in the Workplace®, Chapter 3 covers special electrical equipment in the workplace and modifies the general requirements of Chapter 1.

Can a battery be placed in an ESWC?

The system’s output may be able to be placed into an electrically safe work condition (ESWC), however there is essentially no way to place an operating battery or cell into an ESWC. Someone must still work on or maintain the battery system. Working on a battery should always considered energized electrical work.

Learn More

- What are DC panels and battery cabinets

- DC battery cabinet grounding requirements and standards

- What products are energy storage battery cabinets used for

- What are the manufacturers of outdoor communication battery cabinets in Djibouti

- What are the companies that make battery cabinets in Malaysia

- What kind of self-service battery replacement cabinets are there in North Asia

- What battery cabinets are there in Havana

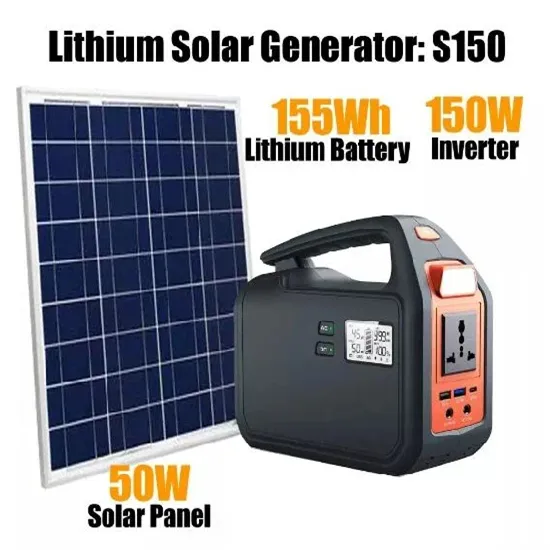

- What are the portable mobile energy storage battery cabinets

- Quality requirements for energy storage battery cabinets

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.