Inverter Alarm DC Arc Fault

Mar 29, 2025 · CONCLUSION A DC arc fault is usually caused by an open circuit or poor contact with a PV string. Serious DC arc faults can even cause fires. Therefore, during routine

Technical White Paper: Arc Fault Circuit Interrupter (AFCI) for

What''s the best way to deal with DC arcing? Arc Fault Circuit Interrupter with AI! Huawei together with leading testing and certification organization China General Certification Center (CGC)

ทำไมอาร์คกระแสตรงถึงน่ากลัว

Jul 18, 2022 · ระบบ AFCI หรือ Arc Fault Circuit Interrupter คือวงจรที่ทำการตรวจสอบการเกิดอาร์ค

2039 AC Overcurrent

Apr 25, 2025 · Inverter,AlarmSuggestion The device detects its external working conditions in real time. After the fault is rectified, the device automatically recovers. If the alarm occurs

DC ARC DETECTION AND INTERRUPTION IN

Jul 6, 2023 · The results demonstrate the effectiveness of the Huawei Solar Inverter in mitigating the risks associated with DC arc faults, including the prevention of fires caused by DC series

Huawei photovoltaic inverter dynamic test

Jul 23, 2022 · To verify the performance and availability of arc-fault circuit interrupter (AFCI),Huawei entrusted the China General Certification Center (CGC) to complete

Dc arc detection and interruption in photovoltaic

Jul 6, 2023 · The results demonstrate the effectiveness of the Huawei Solar Inverter in mitigating the risks associated with DC arc faults, including the

Technical White Paper: Arc Fault Circuit Interrupter (AFCI) for

DC arcing is one of the biggest safety hazards in rooftop PV plants. However, arc noise is generally weak and only accounts for 0.1% of the normal current signal, which often leads to

AFCI เทคโนโลยีเพื่อความอุ่นใจที่

Aug 8, 2024 · ระบบโซล่าเซลล์เป็นการลงทุนที่คุ้มค่า แต่ความปลอดภัยก็เป็นสิ่งสำคัญที่ไม่ควรมองข้าม Huawei Inverter

6 FAQs about [Huawei inverter DC arc]

Do Huawei inverters meet UL 1699b-2018 arc fault circuit protection requirements?

To verify the performance and availability of arc-fault circuit interrupter (AFCI), Huawei entrusted the China General Certification Center (CGC) to complete comprehensive evaluation, with its results showing that Huawei inverters with the AFCI function meet the requirements of UL 1699B-2018 "Safety Standard for PV DC Arc Fault Circuit Protection."

Where are Huawei AFCI inverters used?

Huawei inverters with the AFCI function have been successfully applied in many countries and regions, such as China, North America, Europe, Asia Pacific, Latin America, Southeast Asia, the Middle East, and Africa. Complies with the UL 1699B-2018 standard and reaches the L4 level in CGC/GF 175:2020.

How does Huawei arc detection work?

This algorithm enables accurate detection of electric arc faults, allowing for swift protection by shutting off the inverter within 0.5 seconds. With this advanced approach, Huawei ensures efficient arc detection and timely mitigation of potential hazards.

How can Huawei detect electric arc faults?

However, Huawei has successfully developed an intelligent, precise, and rapid solution by leveraging a neural network algorithm. This algorithm enables accurate detection of electric arc faults, allowing for swift protection by shutting off the inverter within 0.5 seconds.

What is Huawei's intelligent arc detection solution?

By combining these elements, Huawei’s intelligent arc detection solution offers enhanced capabilities for accurate and efficient arc detection. Furthermore, the “AI BOOST AFCI” model has undergone significant enhancements to enable effective identification of arc characteristics across various scenarios.

What is DC arc detection (AFCI)?

Recognizing this need, Huawei has introduced inverters equipped with DC arc detection (AFCI) functionality specifically designed for distributed photovoltaic systems, including residential installations. These advanced features aim to mitigate the risk of electrical fires and elevate the overall safety and performance of PV system

Learn More

- Inverter connected to DC battery

- Canberra DC Inverter Installation

- Huawei grid-connected inverter brand

- Huawei Berlin Power Inverter

- DC Inverter Wholesale

- Can Huawei s three-phase photovoltaic inverter be connected to the single-phase grid

- Baghdad Communication Base Station Inverter Huawei

- DC 12V to 60V inverter

- Huawei 400 kW photovoltaic inverter

Industrial & Commercial Energy Storage Market Growth

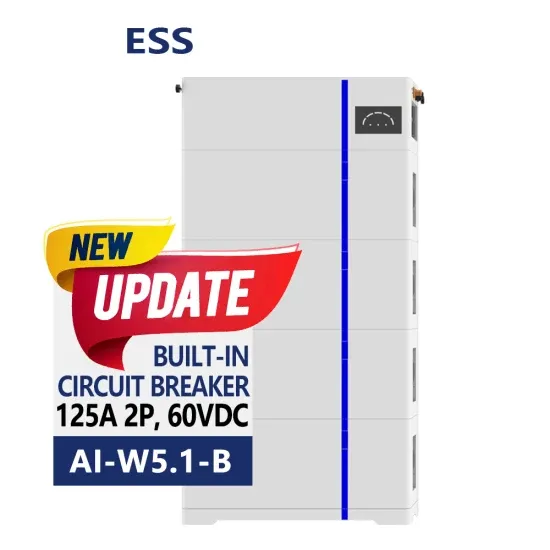

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.