Solar Power Manufacturing Plant Report 2025: Setup Details

4 days ago · The report provides insights into the landscape of the solar power industry at the global level. The report also provides a segment-wise and region-wise breakup of the global

Cost Guide To Installing A Solar Panel In Malaysia

Oct 19, 2023 · Below is a table by TNB showing the suggested solar PV size for households with differing electricity bills. Source Another thing to consider

Solar Electricity Cost in India: Key Facts & Figures

May 30, 2024 · Solar electricity cost in India for residential, commercial & industrial setups - Latest prices, incentives & financing options explored.

Factory Price: Cost of Solar Panels and Battery Integration

How does factory production impact the cost of solar panels? By streamlining production processes, factory efficiencies can significantly reduce the cost of solar panels, making them

What Are the 9 Operating Costs of a Solar Panel

Jul 24, 2025 · This resource details strategies on optimizing solar panel factory operating costs while staying competitive in the renewable energy market. What Fixed Expenses Are Essential

Solar Energy Installation Process Explained: How

5 days ago · Discover the complete solar farm installation process in India — from site selection to power generation. Learn about costs, construction, and

Solar Module Manufacturing Plant Report 2025: Setup Cost

IMARC Group''s report, titled "Solar Module Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and

Cost to Set Up a Solar Farm in India: A Detailed

Apr 10, 2025 · Discover the cost to set up a solar farm in India, including land, panels, inverters, and permits. Learn about government subsidies, ROI, and

Solar Panel Manufacturing Plant Setup: Machinery Cost

Aug 6, 2025 · IMARC Group''s "Solar Panel Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue"

China Install Solar Power, Install Solar Power Wholesale,

China Install Solar Power wholesale - Select 2025 high quality Install Solar Power products in best price from certified Chinese Solar Charger manufacturers, Power Station suppliers,

6 FAQs about [Factory price solar power setup]

How to manage the running costs in a solar panel manufacturing plant?

In a solar panel manufacturing plant like SolarTech Innovations, managing the running costs is crucial for maintaining a competitive edge. One of the key categories is overseeing the expenses related to equipment maintenance and repair schedules.

How much do solar panels cost?

High-tech production lines backed by automation and AI can require upwards of $2 million to $5 million, depending on the plant’s scale. This cost falls under the overall solar panel manufacturing costs that also include equipment depreciation in solar plants. The solar panel production cost also hinges on the price of raw materials.

What are the costs associated with R&D in a solar panel manufacturing facility?

The costs associated with R&D in a solar panel manufacturing facility can vary significantly, but they typically include: Laboratories and Facilities: Costs for maintaining and equipping laboratories for testing and development. Prototyping: Expenses related to creating prototypes of new solar panel designs or technologies.

How much does it cost to lease a solar plant?

The facility space is a prime asset requiring either lease or mortgage payments. In many industrial areas, lease rates can range from $10 to $20 per square foot, depending on location and amenities. This cost directly influences overall solar panel manufacturing costs and the plant’s capacity for expansion.

How much R&D is needed for a solar panel manufacturing plant?

For a solar panel manufacturing plant, dedicating 5% to 10% of total expenses to R&D can lead to enhancements in energy conversion efficiency and overall product durability. This commitment not only drives future growth but also supports the scaling of solar panel technology investment.

How to reduce solar panel manufacturing costs?

In a state-of-the-art facility like SolarTech Innovations, raw materials including high-purity silicon and specialty glass dominate the solar panel manufacturing costs. Bulk purchase agreements and strategic sourcing have proven to reduce these photovoltaic manufacturing expenses significantly.

Learn More

- High quality 7 5 kw solar inverter factory Price

- Price of wind solar and energy storage power generation system in Brno Czech Republic

- Solar power solutions factory in Bandung

- Malabo Solar Power System Factory

- Cooperative solar power system price

- Hot sale factory price solar powerbox Seller

- Price of solar energy storage cabinet solar power reserve

- Solar power satellite factory in Kyrgyzstan

- Factory price solar powerbox in Nicaragua

Industrial & Commercial Energy Storage Market Growth

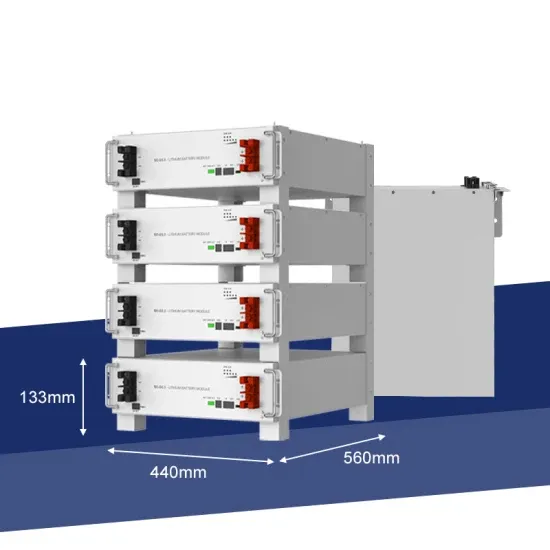

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

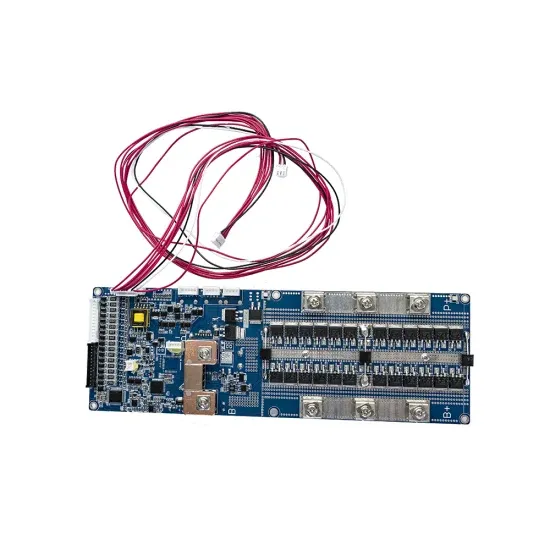

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.