Multifunctional composite designs for structural energy storage

Oct 13, 2023 · Utilizing structural batteries in an electric vehicle offers a significant advantage of enhancing energy storage performance at cell- or system-level. If the structural battery serves

Key Design Principles for Battery Pack Structures in Energy Storage

Nov 25, 2024 · The structural design of battery packs in energy storage systems (ESS) is crucial for ensuring safety, performance, cost-effectiveness, and adaptability across various

Energy storage battery system container design

Simply put, container battery storage refers to a mobile, modular energy storage system housed within a standard shipping container. utility-scale battery storage system with a typical storage

What Does the Container Energy Storage System Consist of?

Jul 6, 2023 · Taking the 1MW/1MWh containerized energy storage system as an example, the system generally consists of energy storage battery system, monitoring system, battery

Development of Containerized Energy Storage System

Dec 24, 2014 · Our company has been developing a containerized energy storage system by installing a varyingly utilizable energy storage system in a container from 2010. The module

Envision Unveils World Largest Energy Storage System,

Nov 6, 2024 · Envision Energy has launched the worlds largest energy storage system at the 3rd EESA Energy Storage Exhibition, featuring a Standard 20-foot Single Container with an

CATL Launches Mass Production of 587Ah Cell,

Jun 20, 2025 · Shanghai, June 10 – At its "True Power" 2025 Energy Storage 587 Technology Day held today, Contemporary Ampere Technology Co., Limited

Containerized Energy Storage System: Structure and

It integrates key components such as battery packs, Battery Management Systems (BMS), energy storage inverters (PCS), and Energy Management Systems (EMS) into a standardized

Container energy storage battery cluster structure

Containerized Battery Energy Storage Systems (BESS) are essentially large batteries housed within storage containers. These systems are designed to store energy from renewable

Structural composite energy storage devices — a review

Mar 1, 2022 · Structural composite energy storage devices (SCESDs) which enable both structural mechanical load bearing (sufficient stiffness and strength) and electrochemical

Structural design of energy storage container power

Container energy storage, also commonly referred to as containerized energy storage or container battery storage, is an innovative The Battery Energy Storage System (BESS)

6 FAQs about [Energy storage container battery cell structure]

What is a containerized battery energy storage system?

Containerized Battery Energy Storage Systems (BESS) are essentially large batteries housed within storage containers. These systems are designed to store energy from renewable sources or the grid and release it when required. This setup offers a modular and scalable solution to energy storage.

What are the challenges in designing a battery energy storage system container?

The key challenges in designing the battery energy storage system container included: Weight Reduction: The container design had to be lightweight yet strong enough to withstand operational stresses like shocks and seismic forces, ensuring the batteries were protected during transport and deployment.

What is a battery energy storage system (BESS)?

The amount of renewable energy capacity added to energy systems around the world grew by 50% in 2023, reaching almost 510 gigawatts. In this rapidly evolving landscape, Battery Energy Storage Systems (BESS) have emerged as a pivotal technology, offering a reliable solution for storing energy and ensuring its availability when needed.

What is the optimal design method of lithium-ion batteries for container storage?

(5) The optimized battery pack structure is obtained, where the maximum cell surface temperature is 297.51 K, and the maximum surface temperature of the DC-DC converter is 339.93 K. The above results provide an approach to exploring the optimal design method of lithium-ion batteries for the container storage system with better thermal performance.

Do lithium-ion batteries perform well in a container storage system?

This work focuses on the heat dissipation performance of lithium-ion batteries for the container storage system. The CFD method investigated four factors (setting a new air inlet, air inlet position, air inlet size, and gap size between the cell and the back wall).

Are energy storage containers a viable alternative to traditional energy solutions?

These energy storage containers often lower capital costs and operational expenses, making them a viable economic alternative to traditional energy solutions. The modular nature of containerized systems often results in lower installation and maintenance costs compared to traditional setups.

Learn More

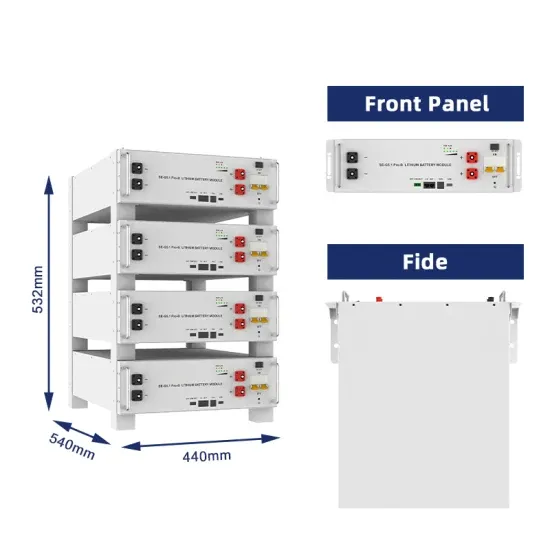

- A battery cabinet structure for energy storage container

- Container energy storage battery cluster structure

- Energy storage container air duct structure

- Minsk energy storage battery container

- Structure of energy storage container

- What kind of battery is the energy storage container battery

- Tajikistan lithium iron phosphate battery energy storage container

- What is the capacity of the container photovoltaic energy storage battery warehouse

- Lithium battery energy storage container bidding information

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.