Assembly strategies for microbe-material hybrid systems in solar energy

Nov 1, 2024 · Herein, we conducted a critical review of microbe-material hybrid systems for solar energy conversion focusing on the perspective of interface assembly strategies between

Solar Power Plants: Types, Components and

Jun 18, 2023 · Solar power plants are systems that use solar energy to generate electricity. They can be classified into two main types: photovoltaic (PV) power

Design and Manufacturing of Dye Sensitized Solar Cell

Mar 8, 2022 · Abstract—There has been steady accretion of power of nonconventional sources of energy one of the viable means discovered is dye sensitized solar cells. The replacement

Solar power generation production and assembly

What is Solar Manufacturing? Solar manufacturing refers to the fabrication and assembly of materials across the solar value chain, the most obvious being solar photovoltaic (PV) panels,

Solar Photovoltaic Technology Basics | NREL

Mar 25, 2025 · Solar cell researchers at NREL and elsewhere are also pursuing many new photovoltaic technologies—such as solar cells made from organic materials, quantum dots,

Solar Panel Manufacturing Process: Step-by-Step Guide

Apr 12, 2025 · Sand → Silicon → Wafer → Photovoltaic Cell → Solar Panel. Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar

Photovoltaics: Basic Principles and Components

Oct 14, 2013 · Photovoltaics: Basic Design Principles and Components If you are thinking of generating your own electricity, you should consider a photovoltaic (PV) system—a way to gen

Fuel Cells for Stationary Power Applications

combustion. This means they produce fewer pollutants than conventional, combustion- based power generation technologies. Fuel cells are also highly efficient, producing more power per

Assembly cell for the manufacturing of flexible solar

Jan 1, 2023 · The current use of photovoltaics is often limited to the utilization of roof surfaces or ground-mounted systems. In particular, building integrated photovoltaics (BIPV) have

6 FAQs about [Assembly of solar cell power generation system]

How are solar panels assembled?

Solar Panel Assembly Once the individual solar cells have been tested, they are interconnected using metal contacts to form a solar panel. The cells are arranged in rows and columns and are soldered together. 8. Lamination

How are solar modules manufactured?

Assembly and Testing: The cells are assembled into modules and undergo thorough testing for efficiency and durability, ensuring they meet the high standards required for solar energy applications. Solar photovoltaic lamination stands as an important step in the solar module manufacturing process.

How long does it take to make solar panels?

The entire solar panel manufacturing process, from silicon wafer production to the final panel assembly, typically takes about 3-4 days. This includes cutting silicon wafers, assembling cells, encapsulating them, and quality testing before shipping.

How a photovoltaic module is assembled?

The assembly of photovoltaic modules consists of a series of consecutive operations that can be performed by automatic machines dedicated to optimizing the single production phases that transform the various raw material in a finished product.

How do solar panels work?

Understanding the manufacturing process of solar panels can help you understand how this technology works. Solar energy can be captured using two primary methods: Photovoltaic (PV) System: This technology converts sunlight directly into electricity using solar panels made of semiconductor materials like silicon.

How to make a solar panel?

The process revolves around ten major steps, which divide into several sub-steps, to produce a complete solar panel. Step 1: Half Cutting Using a laser cutter to divide the cells in two and switching to small area cells in series is a good solution for reducing current losses and increasing module power.

Learn More

- Customized home solar power generation system

- Solar power generation system led

- Shanghai Solar Photovoltaic Power Generation System

- Commercial solar power generation system in Sydney Australia

- Maputo environmentally friendly solar power generation system

- Montevideo Trough Solar Power Generation System

- Small solar power generation system in Bolivia

- Looking for 5Kw solar power generation system

- Tripoli Solar Photovoltaic Power Generation System

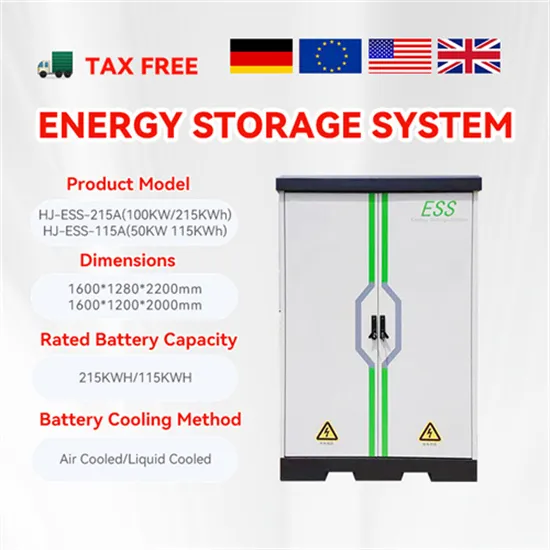

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.