PV Price Watch: China''s polysilicon and wafers see price

Jul 11, 2025 · According to the latest pricing data from the Silicon Industry Branch, released on 9 July, the transaction price range for n-type dense polysilicon has oscillated between

Spatial layout optimization for solar photovoltaic (PV) panel

May 1, 2020 · How to make the best use of a solar photovoltaic (PV) system has received much attention in recent years. Integrating geographic information systems (GIS), this paper

Types of photovoltaic solar panels and their

Nov 6, 2017 · Instead of using silicon in crystalline form, they use a thin layer of photovoltaic material deposited on a substrate such as glass, plastic or metal.

Crystalline Silicon Photovoltaic Module Manufacturing

Feb 10, 2020 · Executive Summary Over the past decade, the crystalline-silicon (c-Si) photovoltaic (PV) industry has grown rapidly and developed a truly global supply chain, driven

A comprehensive review on the recycling technology of silicon

Apr 5, 2024 · In this review article, the complete recycling process is systematically summarized into two main sections: disassembly and delamination treatment for silicon-based PV panels,

Module prices hardly sustaining amid faster polysilicon price

Apr 3, 2024 · The market still showed little interest in purchasing and negotiating as of the eve of the Chinese Qingming Festival. Buyers urgently need lower polysilicon prices due to the risk of

Cost-benefit analysis of waste photovoltaic module recycling

Dec 1, 2020 · With the development of solar PV energy, it is estimated that global solar installed capacity will reach 2.48 TW in 2020 and 8.5 TW in 2050 (IRENA, 2020) and will provide

Photovoltaic silicon panel price trend analysis

Price data providers: A short guide for users. Three Taiwanese market research firms provide weekly spot prices of the products in the solar value chain - solar-grade polysilicon, wafers,

Photovoltaic silicon panel price trend analysis

Download scientific diagram | Silicon wafers price trend. from publication: An Overview of the Photovoltaic Industry Status and Perspective in China | Photovoltaic (PV) is developing rapidly

Photovoltaic (PV) Module Technologies: 2020

Nov 2, 2021 · Photovoltaic (PV) module prices are a key metric for PV project development and growth of the PV industry. The general trend of global PV module pricing has been a rapid and

6 FAQs about [Photovoltaic silicon panel layout and price]

Which solar panel and polysilicon pricing report adheres to Iosco reporting requirements?

The only solar panel and polysilicon pricing report that adheres to IOSCO reporting requirements. The OPIS Solar Weekly Report is the first and only solar panel and polysilicon pricing report to follow the International Organization of Securities Commissions’ (IOSCO) requirements for fair and transparent pricing.

What is NREL analysis of manufacturing costs for silicon solar cells?

NREL analysis of manufacturing costs for silicon solar cells includes bottom-up cost modeling for all the steps in the silicon value chain. Solar Manufacturing Cost Analysis Solar Installed System Cost Analysis Solar Levelized Cost of Energy Analysis Solar Supply Chain and Industry Analysis Solar System Operations and Maintenance Analysis

Why are solar panels so expensive in India?

India: Slight price increases for DCR-compliant modules, driven by government-backed solar PV projects and higher costs for some BOM affected by anti-dumping duties. However, prices for imported modules have declined slightly due to oversupply. United States: FOB prices have remained stable for now.

What is solar technology cost analysis?

NREL’s solar technology cost analysis examines the technology costs and supply chain issues for solar photovoltaic (PV) technologies. This work informs research and development by identifying drivers of cost and competitiveness for solar technologies.

How much does n-type granular silicon cost?

On average, the transaction price for n-type dense polysilicon reached RMB37,100/ton, up 6.92% week-on-week. The transaction price range for n-type granular silicon was RMB34,000-37,000/ton, with an average transaction price of RMB35,600/ton, a 6.27% increase from the previous week.

How much does polysilicon cost?

Wafer (Per Pcs.) This week, the mainstream concluded price for mono recharge polysilicon is RMB 35.5/KG, while mono dense polysilicon is priced at RMB 33.0/KG and N-type granular silicon is currently priced at RMB 32.5/KG. Polysilicon producers continue to hold firm on pricing.

Learn More

- Monocrystalline silicon photovoltaic panel manufacturer

- 900W photovoltaic panel price

- Accra monocrystalline silicon photovoltaic panel charging

- Guyana 500W photovoltaic panel price

- Sucre home photovoltaic panel manufacturer price

- Integrated photovoltaic panel price

- 3kW photovoltaic panel price

- New photovoltaic panel export price

- Zagreb photovoltaic panel flat installation price

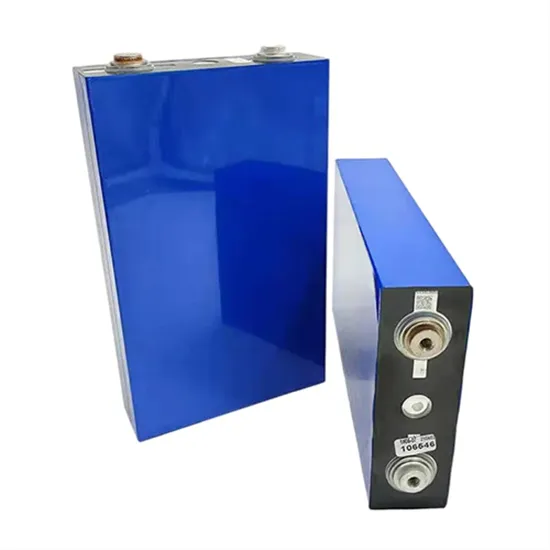

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.