Communication Base Station Inspection | HuiJue Group E-Site

Have you ever wondered why mobile networks suddenly degrade during peak hours? The answer often lies in overlooked communication base station inspections. With 5G deployments

Vehicle mounted base station: a mobile fortress for

Dec 11, 2024 · Vehicle mounted base station is a base station equipment installed on vehicles, which can provide temporary wireless communication coverage, such as emergency

The design and implementation of mobile communication base station

Dec 1, 2012 · In this paper, we design and implement a Mobile Communication Base Station Inspection System by integrating Mobile application development technology and Web

Machine learning for base transceiver stations power failure

Dec 1, 2024 · Base Transceiver Stations (BTSs), are foundational to mobile networks but are vulnerable to power failures, disrupting service delivery and causing user inconvenience. This

Base Station Energy Storage Inspection: The Untapped

Why Your Tower''s Power Backup Might Be Failing Right Now When was the last time your team conducted a comprehensive base station energy storage inspection? With 68% of telecom

Power Base Stations Inspection | HuiJue Group E-Site

Revolutionizing Power Base Station Maintenance Have you ever wondered what keeps 5G networks running smoothly during extreme weather? Power base stations inspection holds the

The design and implementation of mobile communication base station

Dec 31, 2012 · The Mobile Communication Base Station Inspection is one type of basic work to ensure safe operation of the base station equipment. By using the mobile applicati

Distribution station inspection robot with modular manipulator

Jun 1, 2025 · Substation inspection robots play a vital role in ensuring the safety of power grid systems and improving operational efficiency. However, existing inspection robots often face

Investigation on Intelligent Drone-Mounted Mobile

Jan 19, 2024 · Abstract To address the problem of low efficiency of real-time data transmission in areas without signals in the process of transmission lines inspection, the drone-mounted

Mobile robot for power substation inspection: a

Jan 1, 2017 · This paper presents the most important achievements in the field of electric power substation equipment U+02BC s inspection by mobile robot. To

Mobile base station site as a virtual power plant for grid

Mar 1, 2025 · Furthermore, it seeks to determine if the full activation time can meet the requirements of an FFR product. The system consists of a live mobile base station site with a

End to end navigation stack for nuclear power plant inspection

May 1, 2024 · This paper describes a novel approach for nuclear facility inspection with novel automated 3D mapping system as an open source end to end navigation s

Design and realization of 5G mobile base station s

Feb 28, 2024 · The research work of this program design has basically reached the expected requirements, through the user requirements analysis, functional design, database design,

Mobile Robot System Based on Intelligent Inspection of

Mar 8, 2022 · The substation inspection staff pre-set the scope of inspection equipment and inspection content according to the "Technical Specifications of Intelligent Robot Inspection

Base Station Energy Storage Inspection: The Untapped

When was the last time your team conducted a comprehensive base station energy storage inspection? With 68% of telecom outages originating from battery failures (TMA 2023 Report),

The business model of 5G base station energy storage

The literature [2] addresses the capacity planning problem of 5G base station energy storage system, considers the energy sharing among base station microgrids, and determines the

The Application of Inspection Robot in Substation

Feb 8, 2023 · Inspection robot system architecture is shown in Fig. 1, the use of inspection robot for wireless communication devices, base station and mobile station system, to accomplish

Maintenance points for power supply equipment of mobile

The base station power system is one of the supporting systems for mobile main equipment and transmission equipment, involving a variety of professional disciplines such as power

The Application of Inspection Robot in Substation Inspection

Jan 1, 2015 · Inspection robot system architecture is shown in Fig. 1, the use of inspection robot for wireless communication devices, base station and mobile station system, to accomplish

Maintenance of communication base station power supply system

This article discusses how to improve the power supply safety of the power supply system of communication base stations, reduce the failure rate of the power supply system of

Mobile Power Facilities Maintenance System Using

Jun 15, 2022 · In consideration of the above, we developed an AR-based mobile TRS inspection system for facility inspection and control of the TRS switchboard, base station, and terminal

Design and Implementation of Electric Power Patrol Monitoring System

Nov 19, 2020 · Based on current research on electric power inspection and the industry''s urgent need for real-time and accurate location information of inspectors, this paper designed and

Mobile Base Station Lead-Acid Battery Maintenance

Maintenance method of communication mobile base station battery The floating current provided by the switching power supply of the DC system is three effects on the valve-controlled lead

3 FAQs about [Mobile base station power system inspection]

Why do cellular networks need a base transceiver station?

The widespread deployment of cellular networks has improved communication access, driving economic growth and enhancing social connections across diverse regions. Base Transceiver Stations (BTSs), are foundational to mobile networks but are vulnerable to power failures, disrupting service delivery and causing user inconvenience.

What is a Base Transceiver Station (BTS)?

1. Introduction Base Transceiver Stations (BTS) are fundamental building blocks of cellular mobile networks, establishing seamless wireless connection between user equipment and core network for voice calls, data transmission, and short message services , .

Why do mobile network operators face frequent power supply failures at BTS sites?

Mobile network operators (MNOs) face frequent power supply failures at BTS sites, leading to revenue loss and increased operational expenditure (OPEX). Despite their critical role, BTSs face significant operational challenges due to vulnerabilities in their power supply. These disruptions can arise from various external and internal sources .

Learn More

- Mobile communication base station backup power supply

- China Mobile Base Station Backup Power Supply

- Solar hybrid power supply for mobile base station equipment in Paramaribo

- Internal power supply of mobile base station

- Tender for China Mobile s 5G backup base station power supply

- Which mobile communication wind power base station is the best

- Mobile base station equipment photovoltaic power generation system room electrical

- China Mobile base station power problem

- Vatican Mobile Base Station Power Box

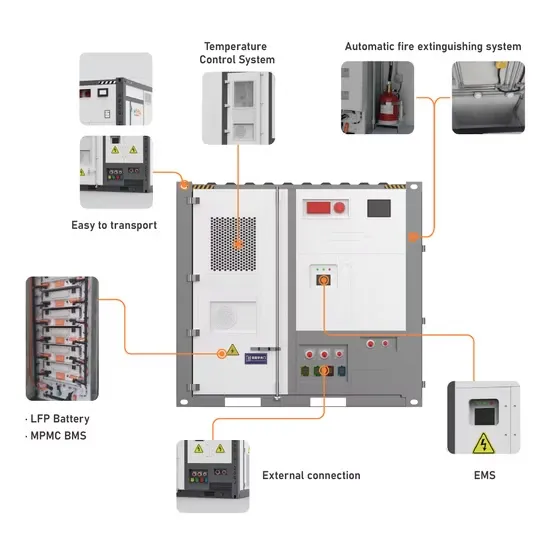

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.