ERITREA LITHIUM ION BATTERY FOR ENERGY STORAGE

Unlike traditional power plants, renewable energy from solar panels or wind turbines needs storage solutions, such as BESSs to become reliable energy sources and provide power on

Lithium Battery Processing in Eritrea Opportunities and

Why Lithium Battery Processing Matters for Eritrea With solar irradiation levels averaging 6.5 kWh/m²/day, Eritrea possesses exceptional potential for solar energy projects. The nation''s

Are lithium iron phosphate batteries all stacked

Are lithium-iron phosphate batteries safe? Lithium-iron phosphate (LFP) batteries are known for their high safety margin, which makes them a popular choice for various applications, including

The Future of Energy Storage: Advantages and Challenges of Lithium Iron

Feb 7, 2025 · Conclusion Lithium iron phosphate batteries are undoubtedly shaping the future of energy storage. Their unparalleled safety, extended lifespan, and cost advantages position

Lithium battery Eritrea material development status

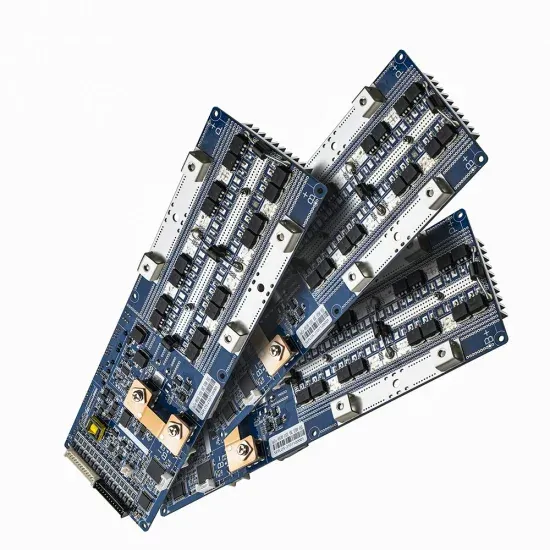

The battery cell formation is one of the most critical process steps in lithium-ion battery (LIB) cell production, because it affects the key battery performance metrics, e.g. rate capability, lifetime

Lithium iron phosphate batteries and energy storage

Why is lithium iron phosphate (LFP) important? The evolution of LFP technologies provides valuable guidelines for further improvement of LFP batteries and the rational design of next

Lithium-ion Battery Technologies for Grid-scale Renewable Energy Storage

Jun 1, 2025 · Furthermore, this review also delves into current challenges, recent advancements, and evolving structures of lithium-ion batteries. This paper aims to review the recent

Characteristics of lithium iron phosphate battery for energy storage

In order to improve the estimation accuracy of the state of charge (SOC) of lithium iron phosphate power batteries for vehicles, this paper studies the prominent hysteresis phenomenon in the

Solar lithium iron phosphate energy storage battery

What are lithium iron phosphate batteries (LiFePO4)? However,as technology has advanced,a new winner in the race for energy storage solutionshas emerged: lithium iron phosphate

Eritrea EK lithium iron phosphate energy storage battery

A new 1GWh lithium iron phosphate (LFP) battery factory in Turkey serving the energy storage system (ESS) market will start production in Q4 2022, said Pomega Energy Storage

Energy storage lithium iron phosphate battery manufacturing

Why is lithium iron phosphate (LFP) important? The evolution of LFP technologies provides valuable guidelines for further improvement of LFP batteries and the rational design of next

High-performance photovoltaic energy storage batteries | EK Solar Energy

Energy storage batteries are battery systems used to store electrical energy. They are able to convert electrical energy into chemical energy, store the charge in the battery, and then

WHY LITHIUM IRON PHOSPHATE BATTERIES ARE USED FOR ENERGY STORAGE

Why is lithium iron phosphate (LFP) important? The evolution of LFP technologies provides valuable guidelines for further improvement of LFP batteries and the rational design of next

Lithium Iron Phosphate Batteries: 3 Powerful Reasons to

May 7, 2025 · The Battery Revolution: Understanding Lithium Iron Phosphate Lithium iron phosphate batteries are rechargeable power sources that combine high safety, exceptional

Lithium Iron Phosphate Batteries: Understanding the

Aug 3, 2023 · In this blog, we highlight all of the reasons why lithium iron phosphate batteries (LFP batteries) are the best choice available for so many rechargeable applications, and why

Past and Present of LiFePO4: From Fundamental Research to

Jan 10, 2019 · In this overview, we go over the past and present of lithium iron phosphate (LFP) as a successful case of technology transfer from the research bench to commercialization. The

Advantages of Lithium Iron Phosphate (LiFePO4)

Mar 9, 2021 · Lithium iron phosphate use similar chemistry to lithium-ion, with iron as the cathode material, and they have a number of advantages over their

Eritrea lithium energy storage power supply spot

As is seen from Fig. 6 [42], electrochemical energy storage equipment based on lithium iron phosphate can absorb energy with immense power and reduce power deviation, which is an

Lithium-iron Phosphate (LFP) Batteries: A to Z

Mar 28, 2023 · These batteries have gained popularity in various applications, including electric vehicles, energy storage systems, and consumer electronics.

TOP LITHIUM ION BATTERY OEM SUPPLIERS IN ERITREA

With the widespread adaptation of solar energy sources like solar panels, lithium iron phosphate batteries have gained much popularity as well. They offer many advantages that include high

Photovoltaic panel energy storage lithium iron

What are lithium iron phosphate batteries (LiFePO4)? However,as technology has advanced,a new winner in the race for energy storage solutionshas emerged: lithium iron phosphate

Lithium iron phosphate battery energy storage unit

Lithium iron phosphate battery energy storage unit The lithium iron phosphate battery (LiFePO4 battery) or LFP battery (lithium ferrophosphate) is a type ofusing (LiFePO4) as thematerial,

6 FAQs about [Eritrea EK lithium iron phosphate energy storage battery]

Are lithium-iron phosphate batteries a good energy storage system?

Lithium-iron phosphate (LFP) batteries are just one of the many energy storage systems available today. Let’s take a look at how LFP batteries compare to other energy storage systems in terms of performance, safety, and cost.

What is a lithium-iron phosphate (LFP) battery?

These batteries have gained popularity in various applications, including electric vehicles, energy storage systems, and consumer electronics. Lithium-iron phosphate (LFP) batteries use a cathode material made of lithium iron phosphate (LiFePO4).

Is lithium iron phosphate a successful case of Technology Transfer?

In this overview, we go over the past and present of lithium iron phosphate (LFP) as a successful case of technology transfer from the research bench to commercialization. The evolution of LFP technologies provides valuable guidelines for further improvement of LFP batteries and the rational design of next-generation batteries.

Why is lithium iron phosphate (LFP) important?

The evolution of LFP technologies provides valuable guidelines for further improvement of LFP batteries and the rational design of next-generation batteries. As an emerging industry, lithium iron phosphate (LiFePO 4, LFP) has been widely used in commercial electric vehicles (EVs) and energy storage systems for the smart grid, especially in China.

Are lithium-iron-phosphate batteries safe?

Safety concerns surrounding some types of lithium-ion batteries have led to the development of alternative cathode materials, such as lithium-iron-phosphate (LFP). LFP batteries offer several advantages over other types of lithium-ion batteries, including higher safety, longer cycle life, and lower cost.

Are lithium-ion batteries safe?

Lithium-ion batteries have become the go-to energy storage solution for electric vehicles and renewable energy systems due to their high energy density and long cycle life. Safety concerns surrounding some types of lithium-ion batteries have led to the development of alternative cathode materials, such as lithium-iron-phosphate (LFP).

Learn More

- The life of the new lithium iron phosphate battery as energy storage system

- Bosnia and Herzegovina lithium iron phosphate energy storage lithium battery

- Bangladesh lithium iron phosphate energy storage battery

- Riga lithium iron phosphate battery energy storage container sales

- Spanish lithium iron phosphate energy storage battery

- Lithium iron phosphate energy storage battery 14 kWh

- How long can the lithium iron phosphate battery of the energy storage cabinet be used

- Lithium iron phosphate RV energy storage lithium battery

- Tajikistan lithium iron phosphate battery energy storage container

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.