Top 10 Photovoltaic Glass (PV Glass) Supplier in

Apr 8, 2025 · As the global demand for clean energy continues to rise, China has solidified its position as a leader in photovoltaic (PV) glass manufacturing. The

Solar Photovoltaic Glass: Classification and

Jun 26, 2024 · Demand for solar photovoltaic glass has surged with the growing interest in green energy. This article explores ultra-thin, surface-coated, and

Solar Photovoltaic Glass Market Size, Share Analysis

Oct 12, 2020 · Rising prices for photovoltaic glass stimulate the fragile hearts of component manufacturers, fearing that photovoltaic glass will become the baton that controls the price of

Experimental repair technique for glass defects of glass-glass

Aug 1, 2023 · A failure of growing importance is the defect in the glass layer (s) of glass-glass PV modules. In this research, an experimental glass repair technique for glass-glass PV modules

How High Can Photovoltaic Panel Glass Temperatures Get in

Photovoltaic panel glass typically endures surface temperatures between 65°C to 85°C (149°F to 185°F) during peak summer conditions. But here''s the kicker: Recorded desert installations hit

How does the temperature range of thermochromic photovoltaic glass

Dec 22, 2024 · Triggering Transformation: The latest iterations of thermochromic photovoltaic glass change color and functionality within a temperature range of 95°F to 115°F (35°C to

Corporate Profile_About Flat_Flat Glass Group Co., Ltd

Flat Glass Group Co., Ltd, located at Xiuzhou National High-tech Zone, Jiaxing City, Zhejiang Province, occupies an area of more than 370,000m2 with a covered area of more than

The Current Situation and Future Prospects of Photovoltaic

May 20, 2025 · Imagine a world where every skyscraper window and car sunroof doubles as a solar panel. That''s the promise driving photovoltaic glass factories worldwide. As global solar

What is the Difference Between Solar Photovoltaic Glass and Float Glass?

May 30, 2024 · Photovoltaic (PV) glass, used in solar panels, features special coatings for efficiency and durability, while float glass, used in construction and automotive industries, is

Solar glass manufacturer sets new benchmark -

May 6, 2015 · Chinese PV glass manufacturer Chang Zhou Almaden Ltd is to imminently open a new photovoltaic glass manufacturing and training facility in Dubai. The company, one of the

Assessing the sustainability of solar photovoltaics: the case of glass

Sep 12, 2024 · The life cycles of glass–glass (GG) and standard (STD) solar photovoltaic (PV) panels, consisting of stages from the production of feedstock to solar PV panel utilization, are

How does the temperature range of thermochromic photovoltaic glass

Dec 22, 2024 · The temperature range of thermochromic photovoltaic glass significantly impacts its performance in several key ways: Temperature-Induced Color Change Triggering

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · Life Cycle Assessments (LCA) of single-crystalline silicon (sc-Si) photovoltaic (PV) systems often disregard novel module designs (e.g. glass-glass modules) and the fast pace of

China''s Photovoltaic (PV) Glass sales in 2021-2025 could

Mar 17, 2016 · Stimulated by factors of the policy support, global consensus on carbon neutrality, and the cost reduction of PV power generation, China''s PV glass industry is expected to usher

6 FAQs about [Is the photovoltaic glass factory hot ]

How does Photovoltaic Glass impact the future of manufacturing?

As the world continues to prioritize sustainability and combat climate change, the role of photovoltaic glass in shaping the future of manufacturing becomes increasingly prominent. The integration of PV glass into factory infrastructure aligns with the growing emphasis on renewable energy, energy efficiency, and green building practices.

Where are solar photovoltaic glasses made?

The largest producers of solar photovoltaic glasses are in the Asia-Pacific region. Some of the leading companies in the production of solar photovoltaic glasses are Jinko Solar, Mitsubishi Electric Corporation, Onyx Solar Group LLC, JA Solar Co. Ltd, and Infini Co. Ltd. China is the world’s largest solar photovoltaic glass manufacturer.

What is Solar Photovoltaic Glass?

Solar photovoltaic glass is a technology that enables the conversion of light into electricity. The glass is incorporated with transparent semiconductor-based photovoltaic cells, also known as solar cells. These cells are sandwiched between two sheets of glass, which enables them to capture these solar rays and convert them into electricity.

How big is the Solar Photovoltaic Glass market?

The Market Size and Forecasts for the Solar Photovoltaic Market are Provided in Terms of Volume (tons) for all the Above Segments. The Solar Photovoltaic Glass Market size is estimated at 27.11 Million tons in 2024, and is expected to reach 63.13 Million tons by 2029, growing at a CAGR of 18.42% during the forecast period (2024-2029).

Which region will dominate the Solar Photovoltaic Glass market?

The Asia-Pacific region is expected to dominate the solar photovoltaic glass market. In developing countries like China, India, and Japan, the crisis in electricity supply has resulted in increasing the scope for self-producing electricity using solar photovoltaic glass.

Where are photovoltaic films made?

One notable case study is the Heliatek GmbH factory in Dresden, Germany. This facility, which produces organic photovoltaic films, integrated semi-transparent PV glass into its facade, generating clean energy while maintaining natural light transmission.

Learn More

- Dakar Photovoltaic Glass Factory

- Is a photovoltaic glass factory a photovoltaic factory

- Djibouti Photovoltaic Glass Factory

- Photovoltaic glass factory of St Petersburg Power Plant Russia

- How much is the Lusaka photovoltaic glass factory

- Is there a photovoltaic glass factory in Rwanda

- Is there a photovoltaic glass factory in Bosnia and Herzegovina

- Photovoltaic factory makes glass

- How much is the photovoltaic glass factory in Greece

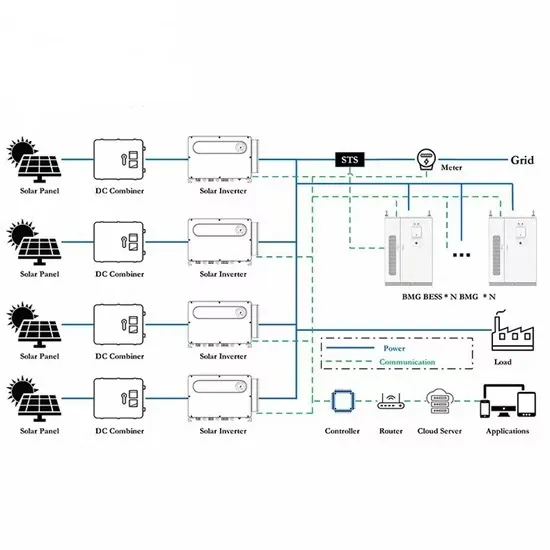

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.