How many strings of 12 volt batteries are needed

A Complete Diagram: How to Connect 2 12 Volt Batteries in When it comes to powering devices or systems that require higher voltages, connecting batteries in series can be a

What is the purpose of batteries at telecom base

Feb 10, 2025 · Among the many types of batteries, why can lead-acid batteries become the first choice for telecom base stations? This is mainly due to its

Optimum sizing and configuration of electrical system for

Jul 1, 2025 · The rising demand for cost effective, sustainable and reliable energy solutions for telecommunication base stations indicates the importance of integration and exploring the

Optimum sizing and configuration of electrical system for

Jul 1, 2025 · Proposed a model for optimal sizing & resources dispatch for telecom base stations. The objective is to achieve 100% power availability while minimizing the cost. Results were

Power Supply Solutions for Wireless Base Stations Applications

For this reason, battery backups and generators are installed in a wireless base station''s power supply system to allow continuous operation under all circumstances.

Use of Batteries in the Telecommunications Industry

Mar 18, 2025 · Both Telecom dc plant and Data Center UPS are considered "Standby Power" Non cycling – 99% of time in "float condition" Batteries only used when commercial power is lost

What Size Battery for Base Station? | HuiJue Group E-Site

New EU Ecodesign mandates effective 2024 require base station batteries to have 90% recyclability. This shifts the calculus toward lithium-based solutions despite higher upfront costs.

How do I calculate how many batteries I need?

Apr 25, 2020 · When using lead-acid batteries it''s best to minimize the number of parallel strings to 3 or less to maximize life-span. This is why you see low voltage lead acid batteries; it allows

Distribution network restoration supply method considers 5G base

Feb 15, 2024 · Aiming at the shortcomings of existing studies that ignore the time-varying characteristics of base station''s energy storage backup, based on the traditional base station

How many strings of batteries are best for base station power supply

Does a base station need a power supply? Base station site planning and network design criteria varies operator to operator but power is often not considered until a particular design state

Machine learning for base transceiver stations power failure

Dec 1, 2024 · Base Transceiver Stations (BTSs), are foundational to mobile networks but are vulnerable to power failures, disrupting service delivery and causing user inconvenience. This

Comprehensive Guide to Telecom Batteries

Oct 14, 2024 · In the fast-paced world of telecommunications, reliable power sources are essential for maintaining connectivity and ensuring uninterrupted service. Telecom batteries play a

Choosing a Power Supply for Your Station

Jan 29, 2021 · For example, the Samlex SEC-1235P-M switching power supply is rated 30A continuous output, 36A peak. If you''re running a VHF/UHF transceiver at home, especially a

Battery Sizing Considerations IEEE 2020

Mar 11, 2020 · The Battery''s Purpose Batteries provide DC power to the switchgear equipment during an outage. Best practice is to have individual batteries for each load/application.

Choosing the right size power supply for your

Apr 16, 2020 · How do you power a mobile radio for use as a base station? Get a power supply. But this isn''t a cut and dry, one-size-fits-all sort of thing.

6 FAQs about [How many strings of batteries are best for base station power supply]

How many Battery strings does a telecom power system have?

The telecom power system at 48VDC has four parallel battery strings of flooded lead-acid cells. Each string is rated 2,260 ampere-hours at an 8-hour discharge rate for a final battery voltage of 1.75V per cell.

Which battery is best for telecom base station backup power?

Among various battery technologies, Lithium Iron Phosphate (LiFePO4) batteries stand out as the ideal choice for telecom base station backup power due to their high safety, long lifespan, and excellent thermal stability.

How many volts does a battery string have?

Each string is rated 2,260 ampere-hours at an 8-hour discharge rate for a final battery voltage of 1.75V per cell. The design provides for one battery string to be disconnected for maintenance, while the remaining strings still support the full load current. The system requires sixteen 100A rectifiers to provide 15+1 redundancy.

How many parallel strings can a battery system have?

Some systems can have as many as 20 parallel strings to support the high steady-state current requirement. The system is designed to allow one string of batteries to be disconnected for maintenance purposes and still support the full load current with a shorter reserve time.

What makes a telecom battery pack compatible with a base station?

Compatibility and Installation Voltage Compatibility: 48V is the standard voltage for telecom base stations, so the battery pack’s output voltage must align with base station equipment requirements. Modular Design: A modular structure simplifies installation, maintenance, and scalability.

How many parallel strings should a lead acid battery have?

When using lead-acid batteries it's best to minimize the number of parallel strings to 3 or less to maximize life-span. This is why you see low voltage lead acid batteries; it allows you to pack more energy storage into a single string without going over 12/24/48 volts.

Learn More

- How long does the base station uninterruptible power supply last

- How much current does the external power supply of the base station have

- How to use the 5g base station power supply to receive correctly

- How much is the base station power supply per ton

- How long can a 200ah battery in a communication base station supply power

- How does the base station power supply work

- How many volts does the base station power supply have

- How to connect the power supply of linkage base station

- How many volts are normal for charging the base station power supply

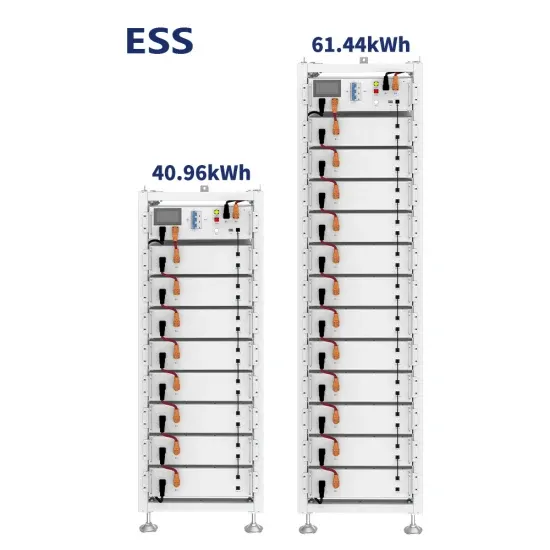

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.