A review of different multi-level inverter topologies for grid

Dec 1, 2022 · A Solar PV Grid integrated network has different challenges such as efficiency enhancement, costs minimization, and overall system''s resilience. PV strings should function

IR 16-8: Solar Photovoltaic and Thermal Systems Review

May 7, 2024 · BACKGROUND Typical solar photovoltaic (PV) panel or thermal systems consist of the solar or thermal panels and their BOS equipment. Building-integrated photovoltaic (BIPV)

Understanding Solar Photovoltaic System Performance

Jan 6, 2022 · Executive Summary This report presents a performance analysis of 75 solar photovoltaic (PV) systems installed at federal sites, conducted by the Federal Energy

Ja Jam66D45-610/Lb a-Level Single Crystal Photovoltaic Panel

Jul 10, 2025 · We offer robust warranties to ensure peace of mind and long-term satisfaction with every purchase. Experience superior quality with our meticulously crafted solar panels,

Guidelines on Rooftop Solar PV Installation for Solar

Oct 25, 2022 · Preface This document provides a general guideline and best practices guide for the installation of rooftop solar PV systems in Sri Lanka. The guide was prepared based on the

Standards and Requirements for Solar Equipment,

Oct 1, 2010 · bigstock/keithpix the National Electrical Code, and Underwriters Laboratories product safety standards [such as UL 1703 (PV modules) and UL 1741 (Inverters)], which are

IEC 61730 2ND EDITION

May 19, 2023 · IEC 61730 2ND EDITION The international standards for photovoltaic (PV) module safety qualification, IEC 61730 series (61730-1 and 61730-2), were recently updated to reflect

Installation Manual for Heliene Photovoltaic Modules

Apr 14, 2021 · The maximum number of panels in a string can be calculated by dividing the maximum system voltage of the panel by its VOC accounting for the lowest ambient

A-level photovoltaic panel parameters

A-level photovoltaic panel parameters What are the critical parameters of photovoltaic (PV)? The most critical parameters of photovoltaic (PV) are: technology,efficiency,and reliability. Silicon is

STANDARDS AND LABELLING OF SOLAR

Mar 25, 2024 · Also, there is an absence of a level playing field in terms of quality products against the cost-competitive substandard ones being sold in the market causing the markets to

The Solar PV Standard

Apr 4, 2023 · A developer wants to install solar panels onto a pair of semi-detached houses which has a cubic capacity of 1000m3 and bounded on three sides by other properties and the fourth

STANDARDS AND LABELLING OF SOLAR

Mar 25, 2024 · As proposed/decided in the TCM ''IS 16170 part1:2015 Photovoltaic (PV) Module Performance Testing and Energy Rating; Irradiance and Temperature Performance

The Core Principles of A-Level Photovoltaic Panels: Efficiency

Conventional panels convert only 15-18% of sunlight into electricity, leaving homeowners dependent on grid backups. Well, here''s the kicker: A-Level photovoltaic panels are changing

Best Practices for Operation and Maintenance of

Apr 26, 2019 · National Renewable Energy Laboratory, Sandia National Laboratory, SunSpec Alliance, and the SunShot National Laboratory Multiyear Partnership (SuNLaMP) PV O&M

Solar Permitting Guidebook 4th Edition

Feb 26, 2019 · This covers photovoltaic system interconnected to the load side of a single-phase AC service panel of nominal 120/240Vac with a bus bar rating of 225A or less. Plan also

Size your solar system

9 hours ago · On this page System size refers to the total capacity of the panels Inverter sizing The available sunny roof area Your electricity usage Electricity pricing The regional climate

Solar Photovoltaic: SPECIFICATION, CHECKLIST AND GUIDE

May 25, 2023 · 1 PURPOSE & SCOPE This Standard specifies the requirements for MCS Contractors undertaking the supply, design, installation, set to work, commissioning and

Best practices for solar system commissioning and

Aug 3, 2020 · Before commercial operations start, solar systems need to pass a set of acceptance and performance tests conducted by the Engineering, Procurement and Construction (EPC)

Standards and Requirements for Solar Equipment,

Oct 1, 2010 · the National Electrical Code, and Underwriters Laboratories product safety standards [such as UL 1703 (PV modules) and UL 1741 (Inverters)], which are design

TECHNICAL SPECIFICATIONS OF ON-GRID SOLAR PV

Feb 3, 2021 · The PV Module should be under the Indigenous / DCR (Domestic Content Requirement) category (Based on the specific requirement). The PV modules shall conform to

Solar Panel Installation: How to Install Solar Step

Jul 8, 2020 · Learn step-by-step instructions for DIY solar panel installation, from selecting the right equipment to setting up your system effectively and safely.

6 FAQs about [A-level photovoltaic panel specifications]

How are solar PV panels rated?

The efficiency ranges for star rating are decided based on the analysis of more than two hundred PV panels across from thirteen PV panel manufacturers. Currently, 60% of the PV panels are spread across 3-star and 4-star ratings (see Table 5). Solar PV panels are covered under CRS(Compulsory Registration Scheme).

What are the specifications for a PV module?

r the specifications for the PV Module is detailed below:The PV modules must be PID compliant, salt, mist & ammonia resistant and shoul withstand weather conditions for the project life cycle.The back sheet of PV module shall be minimum of three layers with outer laye

What are the weights of a PV panel?

The weights (0.14, 0.62 & 0.24) in equation 4 are representative of the percentage of total sunshine hours a PV panel shall be exposed to the respective temperature. The weights are determined by analysing the weather data of thirty-three Indian Cities across five climatic zones.

What are the certification requirements for solar PV modules?

The PV modules shall conform to the following standards:IS 14286: Crystalline silicon terrestrial photovoltai determine the resistance of PV Modules to Ammonia (NH3)The PV module should have IS14286 qualification certification for solar PV modules (Crystalline silicon terrestrial photovoltaic

Should solar PV panels be rated in a single performance rating matrix?

In the technical committee, meeting manufacturers mentioned that combining both the thermal coefficient of power (δ) and efficiency (η) for different types (especially the technology) of Solar PV panels cells in a single performance rating matrix may not be the technically correct way of rating a PV panel(Table 1).

What is the minimum array area requirement for a solar PV inverter?

Although the RERH specification does not set a minimum array area requirement, builders should minimally specify an area of 50 square feet in order to operate the smallest grid-tied solar PV inverters on the market.

Learn More

- Western European flexible photovoltaic panel specifications manufacturers

- EK New Energy Photovoltaic Panel Specifications

- Botswana 15v photovoltaic panel specifications

- Photovoltaic panel types and specifications

- Single column photovoltaic panel specifications

- Sophia Northwest Photovoltaic Panel Specifications

- Photovoltaic panel assembly specifications

- New Delhi s new photovoltaic panel specifications

- Lesotho 7v photovoltaic panel specifications

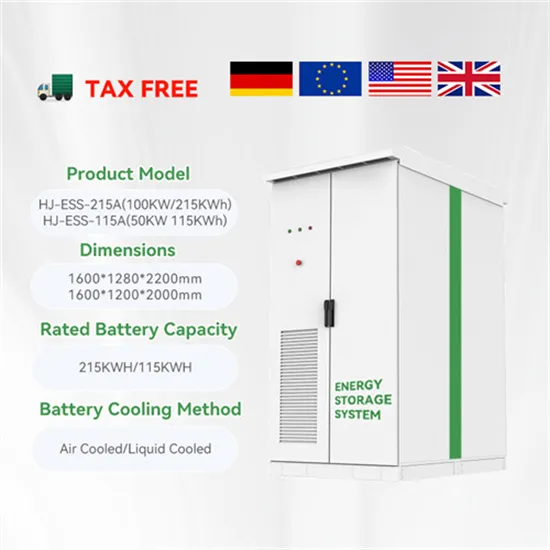

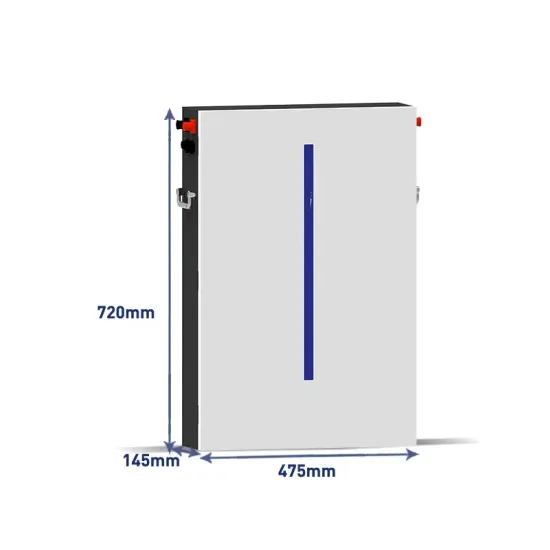

Industrial & Commercial Energy Storage Market Growth

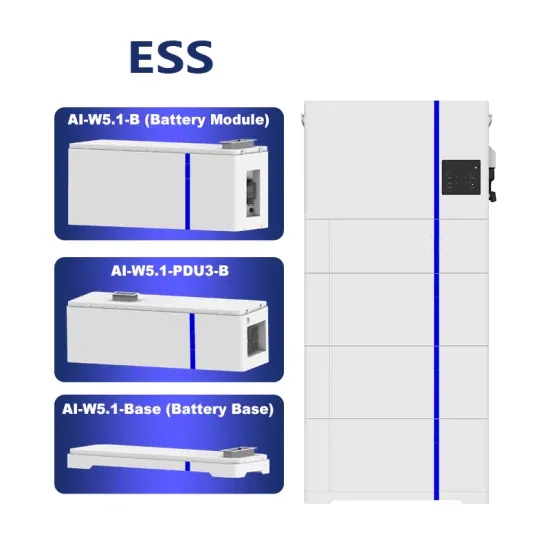

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.