Design and implementation of three-phases energy storage

Jul 5, 2025 · Abstract This paper presents the hardware design for a three-phases energy storage system connected to the grid through a safe isolation transformer, suitable for use in university

Control Strategy of Three-Phase Battery Energy Storage

Sep 24, 2013 · Frequency control in autonomous microgrids (MG) with high penetration of renewable energy sources represents a great concern to ensure the system stability. In

Three-Phase Battery Energy Storage System

May 14, 2019 · Figure 4 shows a three-phase battery energy storage system (BESS) comprising of Buck/Boost DC-DC converter and voltage source converter (VSC). A general description of

Felicityess 50kw High Voltage Three Phase Hybrid Inverter for Energy

Apr 14, 2025 · Felicityess 50kw High Voltage Three Phase Hybrid Inverter for Energy Storage, Find Details and Price about Solar Hybrid Inverter ODM Solar Hybrid Inverter from Felicityess

Wattsonic Li-HV Residential Three Phase Hybrid Series

Apr 7, 2025 · Li-HV Residential Three Phase Hybrid Inverter Options 6-20KW-20/40A-40P GEN 3.0 HV Battery Options 3.84 kWh, per inverter Series w F T TSONIC w FTTSONIC w RX T

Photovoltaic 100-Degree Energy Storage: Solving High

May 30, 2025 · Why Does 100-Degree Heat Cripple Photovoltaic Performance? Ever wondered why solar farms in Arizona lose 20% efficiency during heatwaves? Photovoltaic systems face a

Design and implementation of three-phases energy

Jul 14, 2025 · Experiments were conducted on a 3-phase 380(V) power grid through an isolation transformer and a simulated battery bank powered by the APS1000 amplifier, with a 100(V)

Three-Phase Battery System

Jun 7, 2018 · This example outlines a three-phase battery energy storage (BESS) system. A general description of the functionality of the controllers and the battery system are provided

Mobile Energy Storage 3 Degrees: Powering Flexibility in a

Why Your Coffee Shop Needs a "Battery on Wheels" Let''s face it – our energy needs are messier than a toddler''s birthday party. Enter mobile energy storage 3 degrees systems, the Swiss

Comparison of Two and Three-Level DC-AC Converters

May 24, 2021 · Abstract—This paper discusses a qualitative comparison be-tween Two and Three-Level DC-AC converter topologies for battery energy storage applications. Three-Level

40kW~60kW Three-Phase High Voltage Hybrid Inverter

Mar 17, 2025 · 40kW~60kW Three-Phase High Voltage Hybrid Inverter SSE-HH40K~60K-P3EU three-phase high-voltage hybrid inverter offers high efficiency for commercial and industrial

Modbus Rtu Deye | PDF | Electrical Grid | Mains Electricity

Mar 12, 2025 · The document outlines the MODBUS RTU communication protocol for a three-phase energy storage inverter, detailing its physical interface, data frame format, and error

Three-phase Hybrid Inverter-Yinergy | 易能数字能源

The HI3P Series three-phase hybrid Inverter from Yinergy is a remarkable distributed energy product for home green energy solution. It offers a range of power options from 5kW to 1kKW

产品英文单页20250205

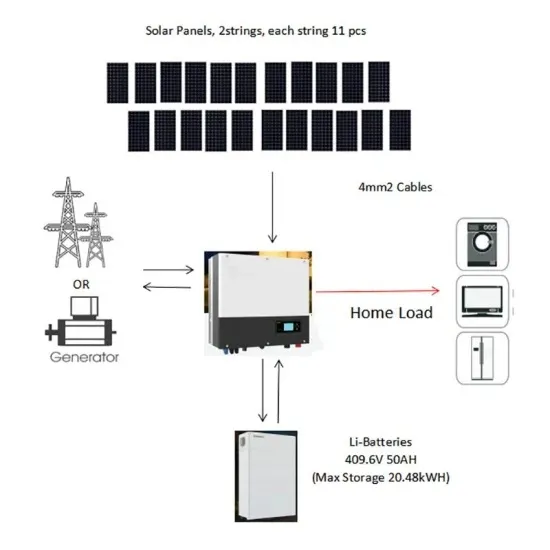

Feb 21, 2025 · The core of the residential energy storage system is the battery pack, BMS, and energy storage inverter, which is paired with household PV to form a residential photovoltaic

Three-phase Residential Energy Storage System

These systems have become the backbone of industrial and commercial energy storage, offering 30% higher power density than single-phase alternatives. Unlike the seesaw effect of single

Green Storage Solar Lithium Battery Storage Factory Three Phase

Aug 18, 2024 · Green Storage Solar Lithium Battery Storage Factory Three Phase Grid Connected PV System China Custom Wall-Mounted Battery for Home Energy Storage

Solis Three Phase High Voltage Energy Storage Inverter S6

Introducing the S6-EH3P50K-H Series. High voltage, three-phase energy storage for commercial applications. The inverter series, which boasts a maximum charge/discharge current of

Design and implementation of three-phases energy storage

Jul 5, 2025 · This paper presents the hardware design for a three-phases energy storage system connected to the grid through a safe isolation transformer, suitable for use in university

Advanced ultra-pressure-resistant three-phase composite

Mar 1, 2025 · Tests on battery modules reveal that a 1 mm thick insulation material extends the average TRP time from 48.5 s to 1046 s, reducing the heat transferred to the adjacent battery

6 FAQs about [Three-phase energy storage battery 100 degrees]

Can a battery energy storage system support the frequency of MG?

In this regard, this paper presents an enhanced control method for battery energy storage systems (BESS) to support the frequency of MG and with the ability of disconnecting from the MG to supplying in the island mode a local consumer.

What is the temperature rise rate of a battery?

A significant volume of gas is expelled alongside sparks, and 3 s later, first jelly roll of battery 1 enters TR. At this stage, T1,f rises sharply, with a maximum temperature rise rate (d T /d tmax) of 78.45 °C/s, reaching a peak front surface temperature (T1,fmax) of 776.6 °C.

What happens if a battery 2 reaches a peak temperature?

Despite the decline in T2,f, exothermic reactions within battery 2 initiate, causing a slight voltage drop. At 1342 s, the accumulated gas inside battery 2 triggers the safety valve, and 3 s later, the first jelly roll of battery 2 undergoes TR, 727 s after the TR of battery 1, reaching a peak temperature of 750.1 °C.

Can a battery withstand a severe mechanical stress during TRP?

However, its low compressive strength is inadequate to withstand the severe mechanical stress during battery TRP. According to prior research and empirical evidence, the expansion force of a battery during TR can easily reach or even exceed 10 kN.

What is the TRP interval between three batteries?

Through calculations, the internal TRP times for the three batteries are determined to be 6 s, 5 s, and 9 s, respectively, while the TRP intervals between the batteries are 43 s and 53 s.

How does thermal resistance affect a battery?

Furthermore, due to the thermal resistance effect of the insulation material, heat transfer is significantly suppressed, and the back surface temperatures of the batteries are no longer significantly higher than the front surface temperatures, as observed in the blank TRP test.

Learn More

- 20 degrees battery energy storage

- Energy storage battery 3 to 5 degrees

- Syria EK energy storage battery 60 degrees

- How to calculate the battery capacity of the energy storage cabinet

- Honduras lithium battery portable energy storage equipment

- Managua Commercial Energy Storage Battery

- Specific direction of lithium battery energy storage

- Battery energy storage system type

- Price of sodium sulfur energy storage battery

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.