How much is the price of photovoltaic panel waste

Dec 11, 2020 · About How much is the price of photovoltaic panel waste Waste from end-of-life solar panels presents opportunities to recover valuable materials and create jobs through

WHO INVENTED SOLAR PANELS?

Photovoltaic solar panel varieties Monocrystalline panels are manufactured from a single crystal of pure silicon. This manufacturing process results in a very uniform material that is characterised

Niamey photovoltaic glass brand ranking

Next-Gen Photovoltaic Modules Engineered for superior efficiency, our photovoltaic modules integrate cutting-edge solar cell technology and anti-reflective coatings to deliver maximum

Assessing the sustainability of solar photovoltaics: the case of glass

Sep 12, 2024 · The life cycles of glass–glass (GG) and standard (STD) solar photovoltaic (PV) panels, consisting of stages from the production of feedstock to solar PV panel utilization, are

Solar Photovoltaic Glass: Classification and

Jun 26, 2024 · Demand for solar photovoltaic glass has surged with the growing interest in green energy. This article explores ultra-thin, surface-coated, and

PV Solar Cell Glass price index

Mar 23, 2024 · Innovations in solar panel technology have led to the emergence of tempered and anti-reflective coated glasses, which significantly enhance the performance of solar panels.

Solar Panel Price in Nigeria: Detailed Cost

Mar 4, 2025 · Solar panel price in Nigeria vary based on a number of factors such as type, size, and wattage. Monocrystalline panels, which offer high efficiency,

How Much Is The Market Price of Double-Glazed Jdsolar Solar Panels

Sep 25, 2024 · JDSOLAR is the world′s leading manufacturer of high performance photovoltaic products for residential, commercial and terrestrial photovoltaic power generation systems.

Solar Installed System Cost Analysis | Solar

Apr 3, 2025 · Solar Installed System Cost Analysis NREL analyzes the total costs associated with installing photovoltaic (PV) systems for residential rooftop,

Is Africa about to see the solar energy boom it needs?

5 hours ago · A record surge of solar panels flowing from China to countries in Africa over the past year is a sign the continent is seeing a rapid build-out of renewable energy.

Solar energy status in the world: A comprehensive review

Nov 1, 2023 · Through a systematic literature survey, this review study summarizes the world solar energy status (including concentrating solar power and solar PV power) along with the

4 FAQs about [How much is the price of Niamey photovoltaic glass panels]

What are PV solar cell glass price developments?

This post is a summary of the PV solar cell glass price developments. The price developments of PV solar cell glass are expressed in US$ prices converted FX rates applicable at the time when the price was valid. PV solar cell glass price index developments are calculated from multiple separate sources of data to ensure statistical accuracy.

How much does non Xinjiang polysilicon cost?

Currently, non-Xinjiang polysilicon with traceability data generally carries a quoted premium of RMB 3–5/kg. Polysilicon prices in dollar terms are prices for polysilicon with non-China origins in dollar terms, not translated from RMB prices.

How are PV production costs modeled?

The costs of materials, equipment, facilities, energy, and labor associated with each step in the production process are individually modeled. Input data for this analysis method are collected through primary interviews with PV manufacturers and material and equipment suppliers.

What is NREL manufacturing cost analysis?

This approach enables NREL to estimate step-by-step costs and identify cost drivers for a given material and production process. Many NREL manufacturing cost analyses use a bottom-up modeling approach. The costs of materials, equipment, facilities, energy, and labor associated with each step in the production process are individually modeled.

Learn More

- How much is the retail price of photovoltaic panels in Cyprus

- How is the price of photovoltaic glass

- How many layers of glass are there in photovoltaic panels

- How to choose a manufacturer to install photovoltaic panels on the roof

- Price of photovoltaic panels in Dubai UAE

- Price difference between monocrystalline and polycrystalline photovoltaic panels

- How many photovoltaic glass companies are there in Rabat

- What is the appropriate price for photovoltaic panels in a BESS house

- Kyrgyzstan new photovoltaic panels selling price

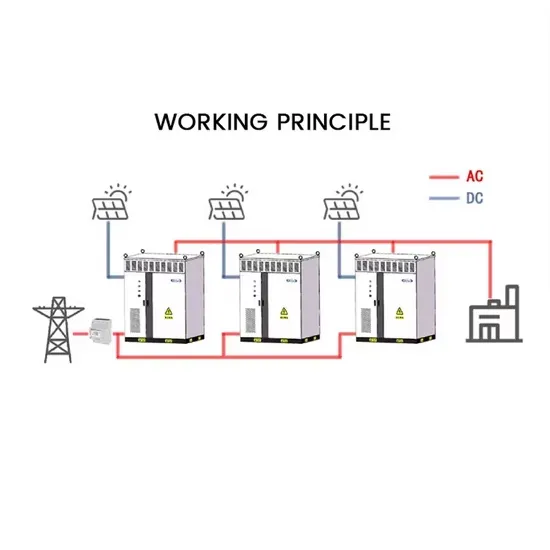

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

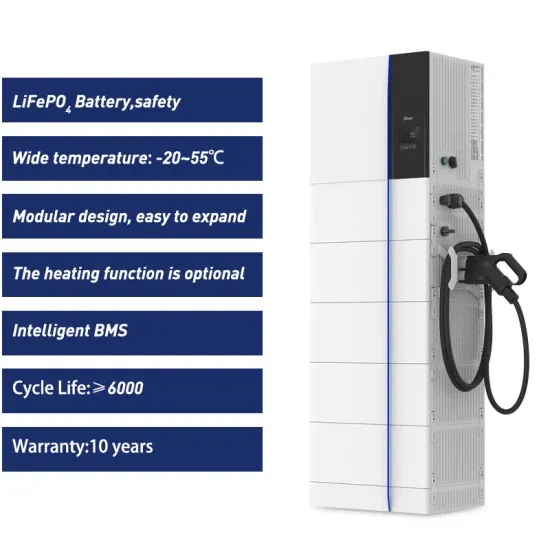

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.