Green Wireless Communication

Apr 28, 2024 · Green wireless communication can be achieved with the use of Green handover, Green codes, Green electronics, Green power amplification systems, Green antennas and

Investigation and Analysis of Energy Efficiency in

Oct 14, 2016 · BS''s alone are consuming much of the energy [4] (approximately 55–60 %) and hence there is a need to introduce green cellular network at base station. From [18], Internet

Unmanned aerial vehicles: Applications, techniques, and

Jan 3, 2022 · to a substitute for desktops, laptops, and other process-ing gadgets. Network operators had to deploy large 1Department of Electronics and Communication Engineering,

The Base Station in Wireless Communications: The Key to

Aug 7, 2024 · Base station, also known as BTS (Base Transceiver Station), is a key device in wireless communication systems such as GSM. Equipped with an electromagnetic wave

The Green Base Station

Jun 13, 2009 · The technology for a Green Base Station is already available, but costs and reliability are two of the most important challenges to solve before the Green Base Station can

The Green Base Station | VDE Conference Publication | IEEE

May 13, 2009 · The Green Base Station which is introduced is equipped with the regenerative energy sources wind power and photo-voltaic energy to reduce the power consumption taken

Carbon emissions and mitigation potentials of 5G base station

Jul 1, 2022 · However, a significant reduction of ca. 42.8% can be achieved by optimizing the power structure and base station layout strategy and reducing equipment power consumption.

An optimal dispatch strategy for 5G base stations equipped

Therefore, this paper proposes an optimal dispatch strategy for 5G BSs equipped with BSCs. Firstly, a joint dispatch framework is established, where the idle capacity of batteries in 5G BS

6 FAQs about [New Delhi Communications Green Base Station Equipped with Equipment]

What is a green base station?

The Green Base Station which is introduced is equipped with the regenerative energy sources wind power and photo-voltaic energy to reduce the power consumption taken out of the public grid to a minimum, whenever sunlight or wind is present.

Are green cellular base stations sustainable?

This study presents an overview of sustainable and green cellular base stations (BSs), which account for most of the energy consumed in cellular networks. We review the architecture of the BS and the power consumption model, and then summarize the trends in green cellular network research over the past decade.

What is SDR soft base station?

The SDR soft base station platform enables a telecom operator to combine networks of different modes and different bands into one network. It simplifies network structure and greatly decreases the number of Network Elements (NEs) and auxiliary facilities, thus reducing power consumption base station power consumption.

What should a base station do in a wireless communications network?

In a wireless communications network, the base station should maintain high-quality coverage. It should also have the potential for upgrade or evolution. As network traffic increases, power consumption increases proportionally to the number of base stations. However, reducing the number of base stations may degrade network quality.

How can a soft base station reduce power consumption?

The 2G/3G swapping project of a leading telecom operator in Asia-Pacific is a good example of how power consumption can be reduced using the SDR soft base station platform. In the old network, one base station used three cabinets for GSM900, GSM1800, and UMTS2100 devices. Its overall power consumption was 4280 W.

How does a green base station reduce the use of lead acid batteries?

Only a small backup battery is used during the start-up time of the fuel cell. Thus, the amount of lead is reduced to a minimum in the Green Base Station. Depending on the system configuration, it is even possible to completely avoid the usage of lead acid batteries.

Learn More

- Kenya Communications Green Base Station Equipment

- New Zealand Communications Green Base Station Cabinet Manufacturer

- New Energy Battery Cabinet Base Station Energy Equipment

- Huawei Communications Green Base Station in Eritrea

- Oceania Communications Green Base Station Photovoltaic Power Generation

- Nuku alofa Communications Green Base Station Construction Unit

- Communication green base station terminal equipment

- Ground wave communication base station inverter grid-connected equipment

- Old communication base station inverter grid-connected equipment

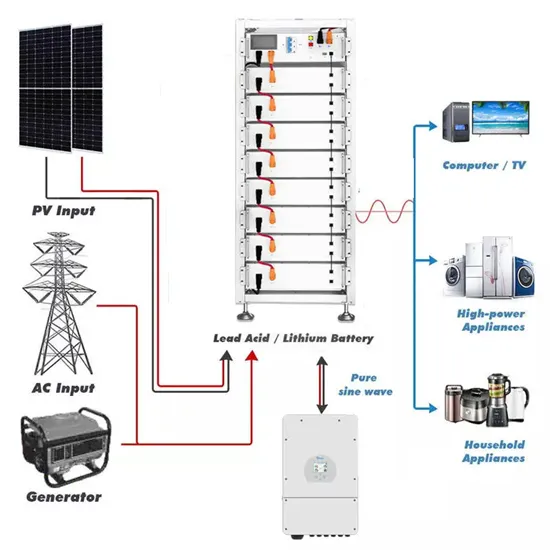

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

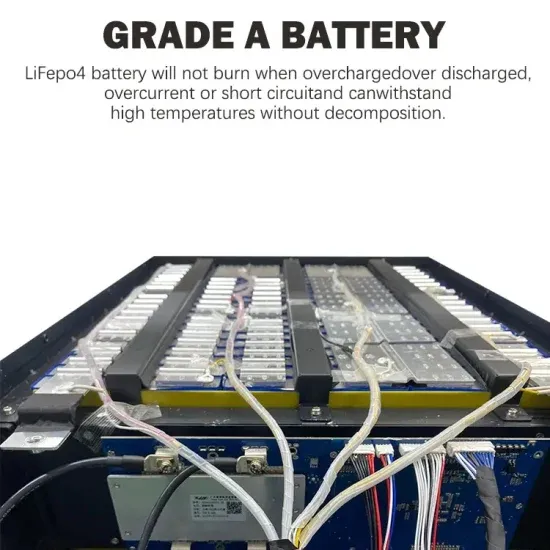

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.