Compressed air cave energy storage power generation

Dynamic Performance of Compressed Air Energy Storage Energy storage technology is an important means to reduce the impact of the fluctuation and intermittency of clean energy

China''s national demonstration project for compressed air energy

On May 26, 2022, the world''s first nonsupplemental combustion compressed air energy storage power plant (Figure 1), Jintan Salt-cavern Compressed Air Energy Sto

Cave Energy Storage and Air Power Generation: The Future

Welcome to the world of cave energy storage paired with air power generation – where ancient geology meets cutting-edge technology. With the global energy storage market hitting $33

Development status and prospect of salt cavern energy storage

Jun 1, 2025 · Energy storage technology is recognized as the core component of the energy supply chain in the 21st century, which can not only greatly improve the grid-connected

Construction Begins on "Salt Cave Compressed Air Energy Storage

Sep 26, 2020 · The Jintan salt cave CAES project is a first-phase project with planned installed power generation capacity of 60MW and energy storage capacity of 300MWh. The non

Jintan Salt Cave Compressed Air Energy Storage Project, a

Oct 2, 2021 · Energy storage is one of the key technologies for building a new power system and achieving the goal of "carbon peak and carbon neutrality". Underground salt caverns have the

Cave Energy Storage and Air Power Generation: The Future

Why Your Next Power Source Might Be Hidden Underground deep within salt caverns beneath the Earth''s surface lies a revolutionary solution to our energy storage headaches. Welcome to

What are the cave energy storage projects? | NenPower

May 18, 2024 · Cave energy storage projects harness the natural formations of underground caverns to store energy, 1. facilitating large-scale storage options, 2. offering a sustainable

6 FAQs about [Cave energy storage power generation]

What is salt cavern energy storage?

In addition, salt rock has little chemical reaction with other substances. As a result, salt caverns have historically been used for many types of energy storage, including oil, petroleum products, natural gas, compressed air, carbon dioxide, and hydrogen (Wang et al., 2018). 2.2. Basic principle of salt cavern energy storage

Can salt caverns be used to build compressed air energy storage systems?

With the growing demand for renewable energy and the continuous development of energy storage technology, the use of salt caverns to build compressed air energy storage systems is gradually becoming a key area of natural gas energy storage systems (Hematpur et al., 2023).

How does a salt cavern affect energy storage capacity?

Salt cavern may creep and deform during long-term use, affecting its energy storage capacity and safety. At the same time, the flow of salt water may lead to the erosion of the salt wall, which in turn affects the structural integrity of the salt cavern.

How to develop a salt cavern energy storage project?

(1) Investment and financing mechanism. The initial investment of the salt cavern energy storage project is huge, including exploration, design, construction and maintenance. In order to promote the development of this technology, an effective investment and financing mechanism must be established.

What is the salt cavern gas storage demonstration project?

The Salt cavern Gas Storage Demonstration project initiated by JX Energy will develop and technologically modify existing salt mines to make them suitable for natural gas storage, and conduct a comprehensive safety assessment to ensure the safe operation of salt cavern gas storage, aiming to improve energy storage capacity and supply elasticity.

What is the economic analysis of salt cavern energy storage?

Economic analysis of salt cavern energy storage The economic analysis of the salt cavern hydrogen storage project involves a number of costs, including pre-capital expenditure (CAPEX), operating expenditure (OPEX) and final unit cost (LCOS).

Learn More

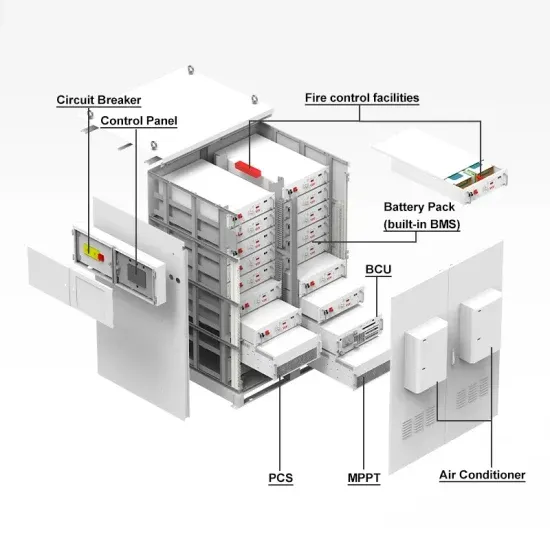

- Containerized power generation and energy storage

- Beirut Energy Storage Photovoltaic Power Generation Products Wholesale

- Honduras Photovoltaic Power Generation and Energy Storage

- Mogadishu Photovoltaic Energy Storage Power Generation Company

- Israel s photovoltaic power generation and energy storage policy

- Thailand 720wmh energy storage power generation project

- Main business photovoltaic power generation energy storage system

- Eritrea communication base station energy storage photovoltaic power generation maintenance

- Photovoltaic power generation to energy storage cabinet

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.