ENERGY STORAGE SYSTEMS FOR VESSELS

Jul 1, 2025 · This thesis conducts a systematic investigation into the development, application, and optimization of energy storage systems (ESS) for modern vessels, aiming to support the

WHAT IS A BYD CONTAINERIZED ENERGY STORAGE SYSTEM

What are the industrial energy storage technology solutions Although many people are familiar with lithium-ion or flow batteries for storing excess renewable energy, industrial enterprises are

Review of energy storage systems for electric vehicle

Mar 1, 2017 · The electric vehicle (EV) technology addresses the issue of the reduction of carbon and greenhouse gas emissions. The concept of EVs focuses on the utilization of alternative

Containerized energy storage vehicles are affordable

Intensium® Energy Storage Systems | Saft | Batteries to energize Battery building blocks. The Intensium ® ranges are standardized to deliver a consistent and holistic design that scales up

Operational risk analysis of a containerized lithium-ion battery energy

Aug 1, 2023 · Lithium-ion battery energy storage system (BESS) has rapidly developed and widely applied due to its high energy density and high flexibility. However, the frequent

WHAT IS A CONTAINERIZED ENERGY STORAGE SYSTEM CESS

What are the industrial energy storage technology solutions Although many people are familiar with lithium-ion or flow batteries for storing excess renewable energy, industrial enterprises are

MW-Class Containerized Energy Storage System Scheme

Dec 30, 2023 · Through the comparative analysis of the site selection, battery, fire protection and cold cut system of the energy storage station, we put forward the recommend

Classification of Industrial and Commercial Energy Storage

Jun 15, 2025 · Industrial and commercial energy storage applications typically involve broader energy management and optimization to enhance efficiency and reduce costs.

Development of Containerized Energy Storage System

Dec 24, 2014 · Some energy storage systems such as pumped hydro storage have existed, but, their large size of such facilities limited potential installation sites, and the energy/utilization

what are the types of containerized energy storage vehicles

Operational risk analysis of a containerized lithium-ion battery energy storage The rapid development of portable electronic devices and electric vehicles has increased demands for

Where are the energy storage vehicles in doha

doha energy storage vehicle standard - Suppliers/Manufacturers. Kinetic energy storage in vehicle to save fuel . Kinetic energy storage in vehicles& it releases when required this way we save

Classification of Industrial and Commercial Energy Storage

Apr 29, 2025 · Industrial and commercial energy storage applications typically involve broader energy management and optimization to enhance efficiency and reduce costs.

what are the types of containerized energy storage vehicles

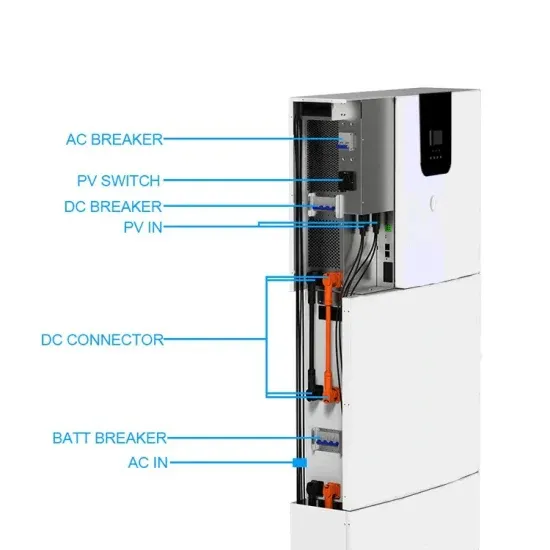

Containerized Energy Storage Systems (CESS) incorporate various essential components that work together to ensure efficient energy storage and delivery. These components include

implementation standards for containerized energy storage vehicles

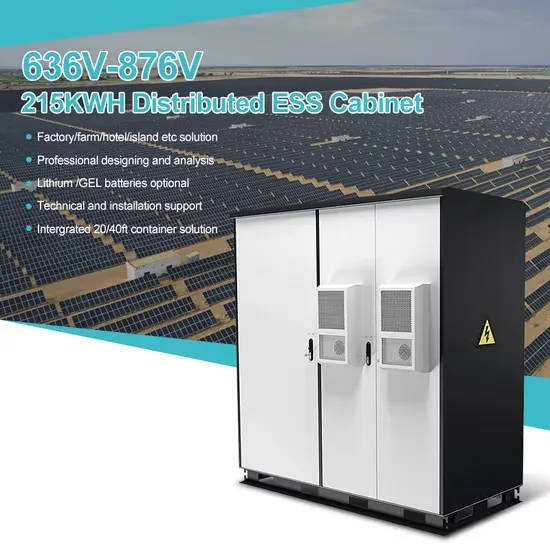

Containerized 215kwh, 372kwh battery energy storage system Containerized energy storage system is a 40-foot standard container with two built-in 250 kW energy storage conversion

CLASSIFICATION OF CONTAINER ENERGY STORAGE

What is a containerized energy storage system? A Containerized Energy Storage System (CESS) operates on a mechanism that involves the collection,storage,and distribution of electric

LFP Battery Storage Systems Shipping Classifications

Apr 19, 2024 · UN 3536: Lithium batteries installed in a cargo transport unit Applications: Shipping or transportation of large-scale lithium battery setups, often in the form of containerized energy

What are the container energy storage charging vehicles

Container energy storage, also commonly referred to as containerized energy storage or container battery storage, is an innovative solution designed to address the increasing

containerized energy storage vehicles

Energy storage container, BESS container All-in-one containerized design complete with LFP battery, bi-directional PCS, isolation transformer, fire suppression, air conditioner and BMS;

CLASSIFICATION OF CONTAINER ENERGY STORAGE

are several approaches to classifying energy storage systems. The most common approach is classification according to physical form of energy and basic operating principle: electric (e

Simulation analysis and optimization of containerized energy storage

Sep 10, 2024 · Furthermore, containerized energy storage systems play a significant role in the transmission, distribution, and utilization of energy sources such as thermal power, wind

集装箱式储能舱:能源存储的未来之星_应用_电网_稳

Sep 20, 2024 · 在能源转型和可再生能源快速发展的背景下,储能技术作为解决能源供需平衡和电网稳定性的关键手段,正逐步成为行业关注的焦点。其中,集

What is the classification of energy storage

Feb 27, 2024 · Energy storage vehicles can be effectively categorized into 1. battery electric vehicles (BEVs), 2. plug-in hybrid electric vehicles (PHEVs), 3.

Development of Containerized Energy Storage System

Dec 24, 2014 · Mitsubishi Heavy Industries, Ltd. (MHI) has been developing a large-scale energy storage system (ESS) using 50Ah-class P140 lithium-ion batteries that we developed. This

energy storage system design and application

MW-Class Containerized Energy Storage System Scheme Design Abstract: Through the comparative analysis of the site selection, battery, fire protection and cold cut system of the

WHAT IS CONTAINERIZED ENERGY STORAGE SYSTEM

What is the energy storage device in electric vehicles A fuel cell works as an electrochemical cell that generates electricity for driving vehicles. Hydrogen (from a renewable source) is fed at the

6 FAQs about [Classification of containerized energy storage vehicles]

How many types of thermal energy storage systems are there?

It was classified into three types, such as sensible heat, latent heat and thermochemical heat storage system (absorption and adsorption system) (65). (Figure 14) shows the schematic representation of each thermal energy storage systems (66). Figure 14. Schematic representation of types of thermal energy storage system. Adapted from reference (66).

What is electrochemical energy storage system?

Electrochemical energy storage system undergoes chemical process to store and produce electricity. Batteries are the most widely used electrochemical energy storage systems in industrial and household applications (28). They are classified into two types namely primary and secondary batteries.

What are the different types of chemical energy storage systems?

The most common chemical energy storage systems include hydrogen, synthetic natural gas, and solar fuel storage. Hydrogen fuel energy is a clean and abundant renewable fuel that is safe to use. The hydrogen energy can be produced from electrolysis or sunlight through photocatalytic water splitting (16,17).

What are the different types of energy storage?

These classifications lead to the division of energy storage into five main types: i) mechanical energy storage, ii) chemical energy storage, iii) electrochemical energy storage, iv) electrostatic and electromagnetic energy storage, and v) thermal energy storage, as illustrated in (Figure 2).

What type of energy storage system stores electrical energy?

Electrostatic and electromagnetic energy storage systems store electrical energy, with no conversion to other forms of energy (i.e., stores as electric field). Capacitors, Supercapacitors and Superconducting magnetic Energy Storage (SMES) belong to this type of energy storage system (32).

What is a CAES energy storage system?

CAES is a technology utilized for storing energy through air compression. This method has found effective application as a large-scale energy storage system, often reaching capacities in the hundreds of megawatts (6).

Learn More

- Who are the manufacturers of containerized energy storage vehicles

- Lobamba containerized energy storage processing

- Benefits of containerized energy storage

- Containerized energy storage system design

- Saint Lucia containerized energy storage company

- Which containerized energy storage companies are there in Ouagadougou

- What is a containerized energy storage cabinet like

- Function of the Dutch containerized energy storage system

- ASEAN containerized energy storage system prices

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.