Building-integrated photovoltaic applied Bi-facial photovoltaic

Jun 1, 2024 · Mechanical load testing of the commercial large-area glass-to-glass photovoltaic module was conducted by increasing the load incrementally, starting at 2400 Pa and

Mechanical Reliability Calculations for the Thin Specialty

Aug 24, 2023 · This study provides important design guidance to the Photovoltaic (PV) solar panel development efforts using the finite element based computations of the PV module

Solar Photovoltaic Glass Market Size, Demand, Opportunities

The global solar photovoltaic glass market size is expected to reach USD 179.08 billion by 2033, growing at a CAGR of 29.87% from 2025 to 2033 And Asia Pacific dominates the market.

Mechanical Reliability Calculations for the Thin Specialty

Solar power utilizes either direct (Photovoltaic (PV) cells) or indirect (lens/mirror tracking) method to convert the sunlight energy into electricity (Chu and Meisen, 2011). In the direct method,

Photovoltaic Module

Jan 9, 2025 · Do not expose the PV module to excessive loads on the surface of the PV module or twist the frame. Do not hit or put excessive load on the glass or back sheet, this may break

JA SOLAR PV MODULES INSTALLATION MANUAL

Jan 29, 2019 · Rooftop PV systems should only be installed on rooftop to be capable of handling the additional weighted load of PV system components, including modules, by a certified

MINIMUM TECHNICAL SPECIFICATIONS OF SPV POWER

Dec 16, 2019 · Definition:- A Grid Tied Solar Rooftop Photo Voltaic (SPV) power plant consists of SPV array, Module Mounting Structure, Power Conditioning Unit (PCU) consisting of

Photovoltaic panel tempered glass load-bearing

typical glass solar panel needs a 45mm frame. Glass by itself is not strong enough to meet the IEC / UL echanical load strength requirements (2400pa). Tempered or not, glass is breakable.

PV Module Safety and Performance Standard

Jan 15, 2020 · Dynamic response Natural frequencies for all modes < ~10 Hz Damping ratio for all modes < ~10 Hz Dynamic amplification factors PV modules Add nonuniform wind-load test

Technical specification requirements for photovoltaic panel

Aug 23, 2021 · The front glass shall meet the following specifications:The facing glass must ickness shall be min 3.2 mmTextured to trap more lightThe glass shall have an Anti-reflective

Analysis of requirements, specifications and regulation

Apr 15, 2020 · This document specifies requirements for appearance, durability and safety as well as test meth-ods and designation for laminated solar photovoltaic (PV) glass for use in buildings.

Glass/glass photovoltaic module reliability and degradation:

Aug 3, 2021 · Abstract Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with additional applications for

Curtain walls

Aug 14, 2025 · Description Technical characteristics Vidursolar glass-glass PV modules are perfectly suitable for fitting as curtain wall as they meet all the requirements for façades of this

The structure of photovoltaic glass solar panels

Solar glass serves as another vital component of a solar panel, forming the outermost layer. It must possess durability and a reflective surface to enhance the panel''''s performance. Solar

Structural Loads for Solar PV Systems and Buildings

Jan 28, 2022 · Rain Load Ponding Check for Buildings with PV For very low-slope roofs, ponding of rainwater can cause excessive deflection, leading to progressive failure. Ponding check is

What are the requirements for photovoltaic panel glass

What is Photovoltaic Glass? Photovoltaic (PV) glass is revolutionizing the solar panel industryby offering multifunctional properties that surpass conventional glass. This innovative material not

Wind Load Calculations for PV Arrays

4 days ago · It is important to evaluate equipment and attachment methods to ensure that PV equipment will remain attached to structures during windstorm events, and that additional

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · This chapter examines the fundamental role of glass materials in photovoltaic (PV) technologies, emphasizing their structural, optical, and spectral conversion properties that

NGA Presents Updated Resource on Glass Properties

Mar 28, 2025 · NGA has published an updated Glass Technical Paper (GTP), FB39-25 Glass Properties Pertaining to Photovoltaic Applications, which is available for free download in the

Assessment of long term reliability of photovoltaic glass–glass modules

Apr 1, 2015 · Quantifying the reliability of photovoltaic (PV) modules is essential for consistent electrical performance and achieving long operational lifetimes.

6 FAQs about [Load requirements for photovoltaic glass]

What are the optimal design parameters for a glass-glass PV module?

This study finds the optimal design parameters of the support structure consisting of two C-Chanel that support the Glass-Glass PV module having thin glass on top and SLG at the bottom. Based on analysis described here, it was found that optimal channel location from free edges is close to L/5 that gives mechanical reliability of 0.99.

What standards are included in a photovoltaic system?

In addition to referencing international electro-technical photovoltaic standards such as IEC 61215, IEC 61646 and IEC 61730, typical standards from the building sector are also included, such as: EN 13501 (Safety in case of fire); EN 13022 (Safety and accessibility in use); EN 12758 (Protec-tion against noise).

Does flat glass improve photovoltaic (PV) panel efficiency?

Flat glass transparency, low-iron glass improves photovoltaic (PV) panel efficiency. This seg- emphasis on energy efficiency and sustainability. Refs. [35, 36]. Based on in-depth analyses of market size, trends, and growth projections. Table 1. Flat glass market. augmented reality and advanced display technologies.

What is laminated Solar Photovoltaic Glass?

This document specifies requirements for appearance, durability and safety as well as test meth-ods and designation for laminated solar photovoltaic (PV) glass for use in buildings. Laminated solar photovoltaic glass is defined as laminated glass that integrates the function of photovoltaic power generation.

Which materials are used in photovoltaic panels?

The remaining 20 –25% encompassed fiberglass (including reinforcement, insulation, and mineral wool fibers) and specialty glass manufacturing . Flat glass transparency, low-iron glass improves photovoltaic (PV) panel efficiency. This seg- emphasis on energy efficiency and sustainability. Refs. [35, 36].

What are the safety standards for PV modules?

The standard defines the basic safety test requirements and additional tests that are a function of the PV module end-use applications. Test categories include general inspection, electrical shock hazard, fire hazard, mechanical stress, and environmental stress. Status: Currently valid standard, but due for regular ISO review.

Learn More

- Photovoltaic glass panel requirements

- Environmental protection requirements for photovoltaic glass

- Which photovoltaic glass product is the best

- Price of photovoltaic curtain wall with power generation glass

- Malaysia Penang Photovoltaic Transparent Glass Manufacturer

- Is photovoltaic glass accurate

- Huawei Lome Photovoltaic Glass Project

- Proportion of photovoltaic glass production sites

- The future growth rate of photovoltaic glass

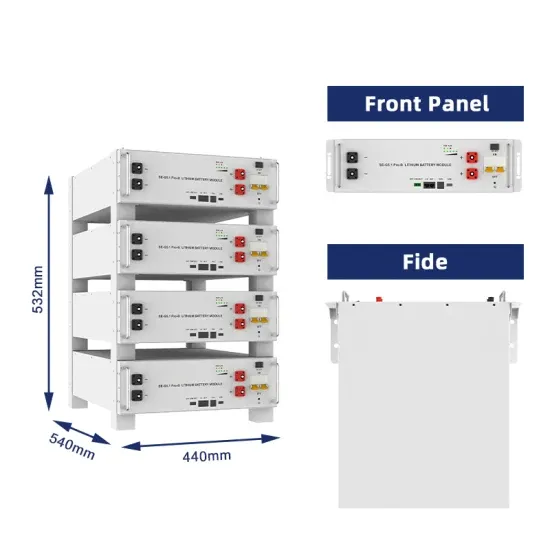

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.