Inside of a wind turbine. | Download Scientific

Oct 24, 2024 · A detailed view from the inside of a wind turbine, the different parts of it and also its serviceability is shown in Fig. 1. due to the development of

10 Best Portable Wind Generators for Eco-Friendly Power on

May 20, 2025 · When you''re on the move, finding reliable energy sources can be a challenge. Portable wind generators offer a practical solution, providing sustainable power for various

How does a wind turbine generate electricity?

May 11, 2025 · The slow-moving main shaft is connected to a gearbox that increases its speed, making the shaft turn fast enough to drive the generator. Generator Produces Electricity: The

What''s Inside a Wind Turbine?

Jan 6, 2016 · The generator at the top of the turbine is producing about 690 volts, and this transformer converts that into several thousand volts to send it more efficiently to the

What''s inside a wind turbine?

May 15, 2025 · An overview of the layout of utility-class wind turbine generators – where are the major components, what do they do, and what differences can be found between models and

What''s Inside a Wind Turbine? 8 Key Components Revealed!

Aug 16, 2025 · The Generator: Igniting the Grid with Wind''s Power At the heart of every wind turbine, nestled high within the nacelle, lies a crucial component that embodies the ultimate

Inside a Wind Turbine: Up Close and Personal

Aug 30, 2024 · Once the gearbox has worked its magic, the generator inside a wind turbine comes into play. This device converts the kinetic energy of wind into usable electrical power

6 FAQs about [Inside the wind power station generator]

How does a wind turbine generator work?

Once the gearbox has worked its magic, the generator inside a wind turbine comes into play. This device converts the kinetic energy of wind into usable electrical power that’s carried through to transformers and substations. The high-speed shaft drives the generator, which uses copper windings to turn through a magnetic field.

What is inside a wind turbine?

Before we explore the inside of a wind turbine, we’ll need to examine the nacelle, which holds several critical mechanical components. This turbine section sits behind the rounded hub and contains the gearbox, generator, break and shafts.

How does a wind turbine gearbox work?

Basically, the gearbox accelerates the speed of rotation of the high-speed shaft to the levels necessary to generate high-voltage electricity with the generator. The gearbox is a costly (and heavy) part of the wind turbine and engineers are exploring “direct-drive” generators that operate at lower rotational speeds and don’t need gearboxes.

How strong is a wind turbine?

So it’s usually very strong. Once the gearbox has worked its magic, the generator inside a wind turbine comes into play. This device converts the kinetic energy of wind into usable electrical power that’s carried through to transformers and substations.

How does a wind turbine yaw work?

The yaw drive orients the wind turbine, while the yaw motor powers it. Together, they work seamlessly to keep the turbine functioning optimally and capturing the maximum kinetic energy available. You’ll typically only find yaw systems on horizontal-axis wind turbines, because vertical-axis turbines have their blades perpendicular to the wind speed.

What is inside a generator tower?

Inside the tower, we can see cables running from the top to the generator, as well as safety systems. This level also houses a ladder and a service elevator, which transports technicians responsible for maintenance, repairs, and inspections of the installation.

Learn More

- Generator Wind and Solar Power Station

- 100kw photovoltaic power station generator

- Malawi communication base station wind power cost

- Base station equipment wind power supply system

- Lisbon trailer power station generator manufacturer

- Belarusian Communication Base Station Wind Power Company

- Design of wind and solar energy storage power station

- Palikir Pumped Storage Power Station Generator Manufacturer

- Canada Island Wind and Solar Energy Storage Power Station

Industrial & Commercial Energy Storage Market Growth

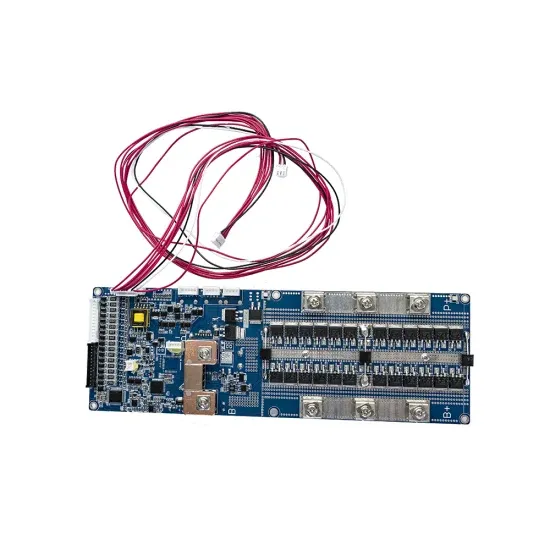

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.