How does LTE manage the transition between different

Oct 6, 2023 · Long-Term Evolution (LTE) networks manage the transition between different states of User Equipment (UE) through a series of signaling procedures and mechanisms. These

What equipment does a household energy storage power station have

Sep 12, 2024 · What equipment does a household energy storage power station have? 1. Household energy storage systems typically consist of several crucial components: 1) Batte

What equipment does a low-voltage energy storage power station have

Feb 1, 2024 · Operating a low-voltage energy storage power station necessitates robust safety protocols to safeguard personnel, the equipment, and the integrity of the facility itself.

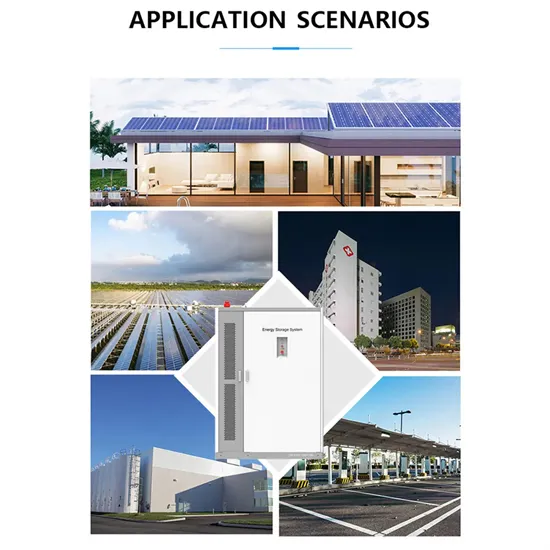

What equipment does an energy storage power station have?

Feb 5, 2024 · Linking an energy storage power station to the existing electrical grid involves numerous components collectively termed grid connection equipment. These elements are

CB Radio Base Station Equipment Recommendations and

The basic components for a Base Station CB System include a CB radio, power supply (if you are using a mobile CB radio instead of a base station CB radio), coax, and an antenna. The article

What is a dedicated power circuit and why do I need one?

Jul 14, 2023 · What is a dedicated power circuit and why do I need one? A dedicated home power circuit is an electrical circuit that is specifically reserved for a par cular appliance or device in a

Energy‐Efficient Base Stations

Aug 29, 2022 · The impact of the Base Stations comes from the combination of the power consumption of the equipment itself (up to 1500 Watts for a nowadays macro base station)

What equipment does the energy storage power station

Jun 12, 2024 · At the heart of energy storage power stations lies a complex network of equipment designed to store, manage, and dispatch energy. Each component possesses distinct

Optimum sizing and configuration of electrical system for

Jul 1, 2025 · Typical configuration of electrical system of a telecommunication base station. The main objective of an Electrical System in telecommunication base station is to provide

Base Station Antennas and Their Technical Essentials

Feb 14, 2025 · In the rapidly evolving 5G landscape, base station antennas, as the core equipment for signal coverage, directly impact communication quality and user experience.

What equipment does the energy storage station include?

Jul 10, 2024 · An in-depth examination of energy storage stations reveals that a multitude of sophisticated equipment and components underpins their operation. The interactions among

Electrical Equipment Used in Power Plants

6 days ago · The following points highlight the seven important electrical equipment used in power plants. The equipment are: 1. Excitation Systems 2. Excitation Control 3. Automatic Voltage

Telecommunication base station system working principle

Jan 13, 2024 · Under normal circumstances, the power supply system operates in a parallel float charging state, where the rectifier module, solar module, load, and battery work in parallel; In

What equipment does a grid-connected energy storage power station have

Jul 10, 2024 · A grid-connected energy storage power station comprises various specialized equipment designed to facilitate energy management and ensure reliable integration with the

Power Consumption Modeling of Different Base Station

Apr 8, 2022 · Energy efficiency of any deployment is impacted by the power consumption of each individual network element and the dependency of transmit power and load. In this paper we

Renewable Energy Sources for Power Supply of Base

Sep 8, 2022 · According to the presented, hybrid systems which combine different renewable energy sources outperform those with only one energy source, and depend on the

6 FAQs about [What equipment does the power-dedicated base station have ]

How much power does a cellular base station use?

This problem exists particularly among the mobile telephony towers in rural areas, that lack quality grid power supply. A cellular base station can use anywhere from 1 to 5 kW power per hour depending upon the number of transceivers attached to the base station, the age of cell towers, and energy needed for air conditioning.

How can the electronic industry reduce power requirements for base stations?

As a result, the electronic industry is exploring new methods to reduce the power requirements for the electronic equipment used in the base stations. The first approach is to make the base stations more tolerant to heat which will then require less power for air conditioning.

What type of generator does a base station use?

The air conditioning of the base station runs at 220 VAC. These base stations can be powered by two types of diesel generators. The first is the conventional type where 220 VAC is converted to 48 VDC to charge the batteries and power the communication equipment.

How to design a solar-powered base station?

In order to design and implement a solar-powered base station, PVSYST simulation software has been used in various countries including India, Nigeria, Morocco, and Sweden. This software allows for estimation of the number of PV panels, batteries, inverters, and cost of production of energy considering the geographical and other design parameters.

Why do Indian telecommunications companies use diesel power base stations?

The increase in demand of power base stations from Indian telecommunication industry is a big challenge, especially in rural India. The majority of these base stations in India use diesel as they are either far from the grid or electricity from the grid is not reliable.

What is the impact of base stations?

The impact of the Base Stations comes from the combination of the power consumption of the equipment itself (up to 1500 Watts for a nowadays macro base station) multiplied by the number of deployed sites in a commercial network (e.g. more than 12000 in UK for a single operator).

Learn More

- What does the communication network base station equipment include

- What equipment does a small communication base station have

- What does civil base station communication equipment include

- What is the base station communication equipment module

- What equipment does communication base station wind power consist of

- What are the communication equipment in the base station room

- What is the use of base station outdoor equipment

- Liberia communication base station battery equipment price

- Paraguay communication base station inverter equipment

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.