铁基氧化还原液流电池研究进展及展望

May 11, 2020 · Redox flow batteries (RFBs) are promising large-scale energy storage t...关键词: 液流电池, 储能, 低成本, 铁基液流电池, 清洁可再生能源

半固态储能电池的研究进展

May 7, 2021 · 关键词: 储能电池, 半固态电极, 流体电池, 新体系 Abstract: The semi-solid energy storage batteries combine the advantages of high energy density of rechargeable batteries

液流电池多孔膜材料研究进展

This review summarizes the latest research development in porous membrane materials for liquid flow battery.More specifically,the working principle,preparation methods and properties

Windhoek liquid cooled energy storage battery price inquiry

Battery Energy Storage Surges as Global Leader Emerges Stendal Energy Storage Project: Nofar Energy and Sungrow are developing a 116.5 MW/230 MWh BESS in Stendal, Germany,

液流电池关键技术突破:解决电池稳定性难题,大幅

Aug 4, 2023 · 为了解决该问题,团队从离子液体的结构中获取灵感,创新性地提出了通过合成TEMPO二聚体(TEMPOD),可以在不显著增加单个TEMPO储

CGN Windhoek Energy Storage Project: Powering Namibia''s

Mar 9, 2024 · Enter the CGN Windhoek Energy Storage Project, Namibia''s bold answer to energy instability. This lithium-ion battery marvel – think of it as a "gigantic phone charger for cities" –

The breakthrough in flow batteries: A step

Jan 6, 2025 · Flow batteries, which store energy in liquid electrolytes housed in separate tanks, offer several advantages over traditional lithium-ion batteries.

Update on Vanadium Flow Battery market, supply chain

Dec 19, 2023 · In the last few years, other flow battery chemistries to gain traction include iron, iron-chrome and zinc-bromine. Some are even looking at vanadium and either iron or chrome

Flow batteries could help energy access in developing

May 4, 2023 · Liquid flow batteries store energy in the electrolyte instead of at the electrodes. The energy stored by the cell can be increased by adding a larger liquid tank, without a

The Windhoek Energy Storage Project: Powering Namibia''s

Dec 30, 2024 · As the sun dips below the Kalahari dunes each evening, this lithium-ion and flow battery hybrid system kicks into gear, storing enough daytime solar energy to power 90,000

China flow battery energy storage project

Lithium-ion batteries accounted for 97 percent of China''''s new-type energy storage capacity at the end of June, the NEA added. A number of compressed air, flow battery and sodium-ion battery

Energy Storage in Windhoek Industrial Park: Powering

Mar 10, 2023 · Welcome to Windhoek Industrial Park, where cutting-edge energy storage solutions are rewriting the rules of sustainable manufacturing. This isn''t just about batteries in

Flow Battery Production Line And Energy Storage Integration

Oct 12, 2022 · On 11 October, the flow battery production line and energy storage integration project with a total investment of about 2.05 billion yuan was signed and settled in the

Review on modeling and control of megawatt liquid flow

Jun 1, 2023 · Megawatt flow battery energy storage system in this paper, investigation and study, from a flow battery energy storage system modeling and control from two aspects introduces

Hengan Energy Storage settled in Beipiao Economic

Apr 30, 2024 · Reference address: Hengan Energy Storage settled in Beipiao Economic Development Zone to create a new highland for zinc-bromine liquid flow energy storage

The world''s first GWh-level new solid-state battery

Nov 21, 2024 · Previous article: The first digital solid-state battery production line settled in Huizhou Marathon solid-state battery production is about to start Next article: Investment and

5 FAQs about [Windhoek liquid flow battery settled]

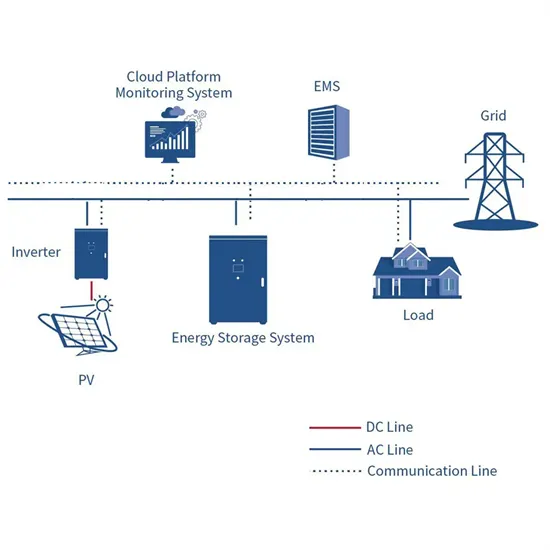

What is liquid flow battery energy storage system?

The establishment of liquid flow battery energy storage system is mainly to meet the needs of large power grid and provide a theoretical basis for the distribution network of large-scale liquid flow battery energy storage system.

Does a liquid flow battery energy storage system consider transient characteristics?

In the literature , a higher-order mathematical model of the liquid flow battery energy storage system was established, which did not consider the transient characteristics of the liquid flow battery, but only studied the static and dynamic characteristics of the battery.

How a liquid flow energy storage system works?

The energy of the liquid flow energy storage system is stored in the electrolyte tank, and chemical energy is converted into electric energy in the reactor in the form of ion-exchange membrane, which has the characteristics of convenient placement and easy reuse , , , .

Can flow battery energy storage system be used for large power grid?

is introduced, and the topology structure of the bidirectional DC converter and the energy storage converter is analyzed. Secondly, the influence of single battery on energy storage system is analyzed, and a simulation model of flow battery energy storage system suitable for large power grid simulation is summarized.

How a flow battery cell works?

Flow batteries The flow battery cell is usually composed of a reactor, electrolyte solution, electrolyte storage tank, pump, etc. The positive and negative electrolytes are respectively stored in the liquid storage tank. Through the circulating pump, the electrolyte will reach the reactor unit from the liquid storage tank along the pipeline path.

Learn More

- Liquid flow battery stack

- Vanadium liquid flow battery cost per watt

- The right is the all-vanadium liquid flow energy storage battery

- Charge and discharge of all-vanadium liquid flow battery

- 30kw all-vanadium liquid flow energy storage battery

- Iranian all-vanadium liquid flow energy storage battery

- All vanadium liquid flow battery companies

- 1GWh all-vanadium liquid flow battery

- Ouagadougou all-vanadium liquid flow battery

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.