HOW TO CONNECT DC POWER SUPPLIES IN SERIES, PARALLEL

Jan 26, 2025 · DC power supplies may be connected in series, parallel or redundant configuration depending on the application need. When higher voltage output than that can be supplied by a

Parallel vs. Series Connection of Power Supplies:

Oct 30, 2023 · In certain scenarios, relying on a solitary power supply may prove inadequate in meeting the energy demands of a load. Multiple power supplies

How Parallel Connections Boost Outdoor Power Supply

May 8, 1986 · Summary: Learn how connecting outdoor power stations in parallel can multiply your energy capacity while maintaining portability. This guide explores practical applications,

How to connect two outdoor solar power supplies in parallel

How to Connect Solar Batteries in Parallel for Maximum Energy Unlock the full potential of your solar energy system by learning how to connect solar batteries in parallel. This comprehensive

Parallel or Series Operation of Switched-Mode

Oct 22, 2021 · A redundant sharing is the control of the power supplies internally or externally by switching only the desired number of the power supplies in

How to Operate Parallel and Series Connection

May 16, 2023 · In general, when selecting a power supply, it is important to choose one with appropriate voltage and current rating to support the system requirements. Typically, power

The Ultimate Guide to Wiring LED Strip Lights to

Apr 7, 2025 · On the power supply side, there are also several options: some, like the Meanwell LPV series, come with open wire outputs; others, like the LRS

Wiring LEDs Correctly: Series & Parallel Circuits

May 27, 2022 · Hopefully, those looking for practical information on electrical circuits and wiring LED components found this guide first. It''s likely though,

How do you connect SITOP power supplies in parallel to increase power

Feb 29, 2024 · To increase power, several SITOP power supplies of the same type can be connected directly in parallel. The output cables connected to each power supply unit at the

How to Wire Lights In Parallel with Switch

Jun 29, 2022 · How To Wire lights in Parallel? Parallel wiring for Lighting Circuits. The following guide will help you and explain about Switch & Lights in a

HOW TO CONNECT DC POWER SUPPLIES IN SERIES, PARALLEL

Jan 26, 2025 · To provide protection against power supply short circuit, it is recommended to connect external diodes (ORing Diodes or Load share modules) when multiple power supplies

Parallel Operation of Power Supplies with User

May 26, 2025 · In system designing, sometimes it is necessary to connect power supplies (PSUs) in parallel to obtain higher power greater than available from

How to Operate Parallel and Series Connection

May 16, 2023 · Typically, power supplies are connected in parallel to increase the power/current rating and also to increase the system reliability by providing redundancy function. Series

How to connect electric heating elements: tips and

4 days ago · In our articles we have already considered options for connecting heaters by connection type (star, delta) and by connection sequence (parallel, series). This article is a

How to Increase the Power Output of Your DC Power Supply

In this article, we show how to increase the power output of your DC power supply by placing it in either parallel mode (to double the current) or series mode (to double the voltage).

How to connect two outdoor solar power supplies in

In addition, DC operated devices can be directly connected to the charge controller (DC load terminals only). To wire two or more solar panels and batteries in parallel, simply connect the

Parallel Operation of Power Supplies with User Systems

Mar 28, 2025 · In this whitepaper, you''ll explore the essential strategies for paralleling power supplies to achieve higher power outputs and robust system redundancy. From understanding

MEAN WELL Switching Power Supply Manufacturer

Active current sharing up to 10 rack shelves (DHP-1UT-B) and the maximum power supply that can be connected in parallel is 40 units Built-in I 2 C interface, support PMBus/CANBus

How to Connect Batteries in Parallel for Your Camper

Dec 20, 2023 · Extended Power Supply: Campers often require a sustained and reliable power supply, especially during outdoor adventures where access to external power sources may be

6 FAQs about [Outdoor power supply parallel connection]

Why are power supplies connected in parallel?

Typically, power supplies are connected in parallel to increase the power/current rating and also to increase the system reliability by providing redundancy function. Series connection of power supplies can cater to special needs of the system when requiring higher output voltages. 1. Parallel Operation

What is a parallel power supply?

Parallel power supplies refer to a configuration where multiple DC power supplies are connected in parallel to increase total output current. Each power supply shares the current load, ensuring that no single unit is overloaded. Higher Current Output – Allows for increased power delivery by combining the output of multiple units.

Why do designers connect power supplies in parallel?

Designers connect power supplies in parallel to obtain a total output current greater than that available from one individual supply as well as to provide redundancy, enhance reliability, avoid PCB thermal issues and boost system efficiency.

Can a DC power supply be connected in parallel?

DC power supplies may be connected in parallel for either increased power output or improved redundancy. When connected in parallel, output current will be 2X of that of one individual power supply.

What is series connection of power supplies?

Series connection of power supplies can cater to special needs of the system when requiring higher output voltages. 1. Parallel Operation The purpose of parallel operation is to get increased output current.

How many power supplies can a parallel PSU run?

In principle, it’s possible to operate as many power supplies as you need to achieve the desired output current. The simplest is two, providing up to double the current. Principle of parallel PSU operation: The load receives at most the sum of the IMAX of the power supplies selected.

Learn More

- Outdoor power supply connection amplifier

- Seamless connection of outdoor power supply

- Can Norway s outdoor power supply be used on public transportation

- Can I have a new outdoor power supply in stock

- Outdoor power supply 70 degrees

- Six hundred yuan outdoor power supply

- BESS Outdoor Power Supply in Canada

- The advantages of large milliamps for outdoor power supply in Southern Europe

- Huawei Kuala Lumpur Customized Outdoor Power Supply

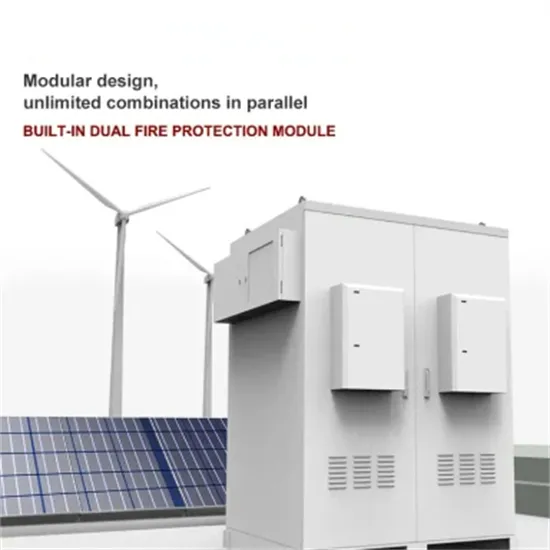

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

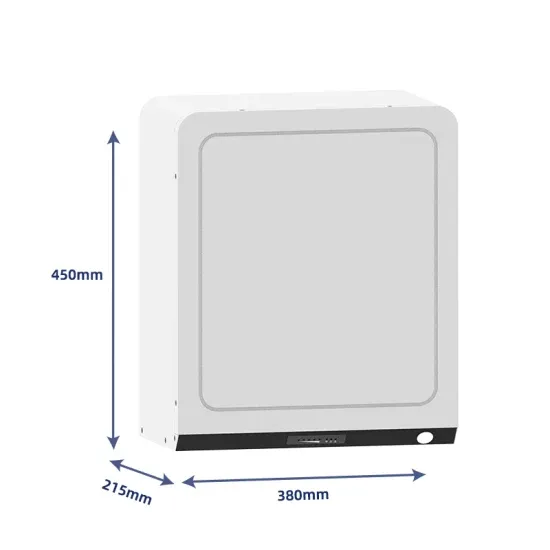

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.