Structural composite energy storage devices — a review

Mar 1, 2022 · Structural composite energy storage devices (SCESDs) which enable both structural mechanical load bearing (sufficient stiffness and strength) and electrochemical

A thermal management system for an energy storage

May 1, 2023 · The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper

Multifunctional composite designs for structural energy storage

Oct 13, 2023 · The resulting multifunctional energy storage composite structure exhibited enhanced mechanical robustness and stabilized electrochemical performance. It retained

Energy storage cabinet structure design atlas

Structural composite energy storage devices (SCESDs) which enable both structural mechanical load bearing (sufficient stiffness and strength) and electrochemical energy storage (adequate

Energy storage emerging: A perspective from

Jun 8, 2020 · In 2010 the cost of lithium (Li)-ion battery packs, the state of the art in electrochemical energy storage, was about $1,100/kWh (2), too high to be

Materials and design strategies for next-generation energy storage

Apr 1, 2025 · Hybrid and advanced multifunctional composite materials have been extensively investigated and used in various applications over the last few years. To meet the needs of

Energy Storage for ALL

Jan 9, 2025 · As renewable energy technologies advance and gain popularity, ESS is becoming a key for the large-scale adoption of renewable energy, addressing issues of intermittency and

Lithium battery energy storage internal structure diagram

Download scientific diagram | Battery energy storage system circuit schematic and main components. from publication: A Comprehensive Review of the Integration of Battery Energy

All in One Li-ion Energy Storage System User Manual

Sep 10, 2024 · The energy storage system is capable of receiving commands from the energy dispatch system and interacting with the energy network and user loads in order to achieve

Containerized Energy Storage System: Structure and

Whether in renewable energy power stations, grid regulation, or industrial parks and remote areas, the containerized energy storage system plays a critical role. Choosing the right energy

Energy storage system structure and principle

The flywheel energy storage system (FESS) offers a fast dynamic response, high power and energy densities, high In this study, a structure-integrated energy storage system (SI-ESS)

Internal Structure of Energy Storage Systems: Core

As renewable energy capacity grew 18% globally in Q1 2025 [虚构], the pressure on energy storage systems (ESS) has never been greater. But what makes these systems tick?

3D internal structure of rechargeable batteries revealed

Mar 13, 2023 · Researchers have pioneered a technique to observe the 3D internal structure of rechargeable batteries. This opens up a wide range of areas for the new technique from

Lead batteries for utility energy storage: A review

Feb 1, 2018 · Lead batteries are very well established both for automotive and industrial applications and have been successfully applied for utility energy storage but there are a

Latent thermal energy storage technologies and applications

Aug 1, 2020 · The article presents different methods of thermal energy storage including sensible heat storage, latent heat storage and thermochemical energy storage, focusing mainly on

Storing Infinite Energy

May 12, 2022 · Participated in Europe''s largest grid-side battery energy storage power station - Minety Battery Energy Storage System in the UK. The 220MWh liquid-cooling energy storage

Materials and design strategies for next-generation energy storage

Apr 1, 2025 · To meet the needs of design Engineers for efficient energy storage devices, architectured and functionalized materials have become a key focus of current research.

6 FAQs about [Internal structure of energy storage products]

What materials can be used to develop efficient energy storage (ESS)?

Hence, design engineers are looking for new materials for efficient ESS, and materials scientists have been studying advanced energy materials, employing transition metals and carbonaceous 2D materials, that may be used to develop ESS.

Why are electrochemical energy storage systems important?

Electrochemical energy storage systems are crucial because they offer high energy density, quick response times, and scalability, making them ideal for integrating renewable energy sources like solar and wind into the grid.

Why do scientists want to develop more efficient energy storage systems?

Hence, Scientists are striving for new materials and technologies to develop more efficient ESS. Among energy storage technologies, batteries, and supercapacitors have received special attention as the leading electrochemical ESD. This is due to being the most feasible, environmentally friendly, and sustainable energy storage system.

Why is energy storage important?

Energy storage is a critical global strategic concern as part of efforts to decrease the emission of greenhouse gases through the utilization of renewable energies . The intermittent nature of renewable energy sources such as solar and wind power requires the implementation of storage technologies.

What contributes to energy storage's progress and evolution?

Continuous advancements, innovative opinions, alternative approaches, and technological breakthroughs from various fields, such as materials science, knowledge management, electrical engineering, control systems, and artificial intelligence, contribute to energy storage's progress and evolution .

What are architectured and functionalized materials?

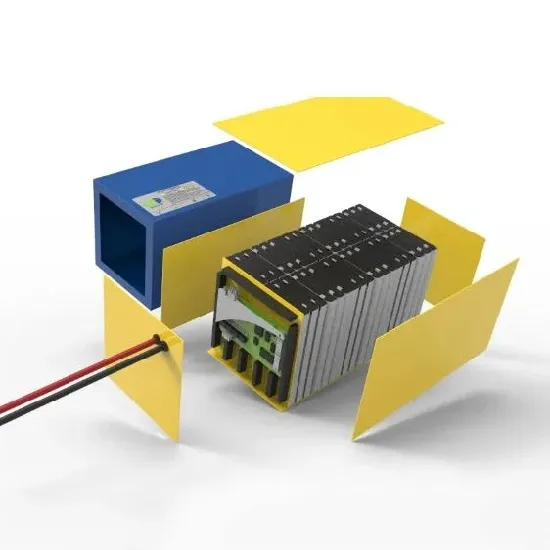

To meet the needs of design Engineers for efficient energy storage devices, architectured and functionalized materials have become a key focus of current research. Functionalization and modification of the internal structure of materials are key design strategies to develop an efficient material with desired properties.

Learn More

- The internal structure of the battery in the energy storage cabinet and the station cabinet

- Internal structure and working of energy storage cabinet

- Discussion of energy storage products

- How much does Seychelles energy storage vehicle products cost

- Products are used in household energy storage equipment

- Introduction to the company s energy storage products

- Nauru Energy Storage Photovoltaic Products Company

- Huawei exports energy storage products to Madrid

- Home Energy Storage Products Company

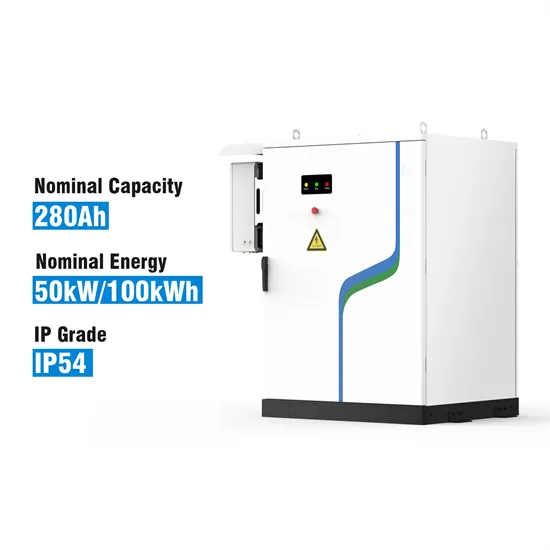

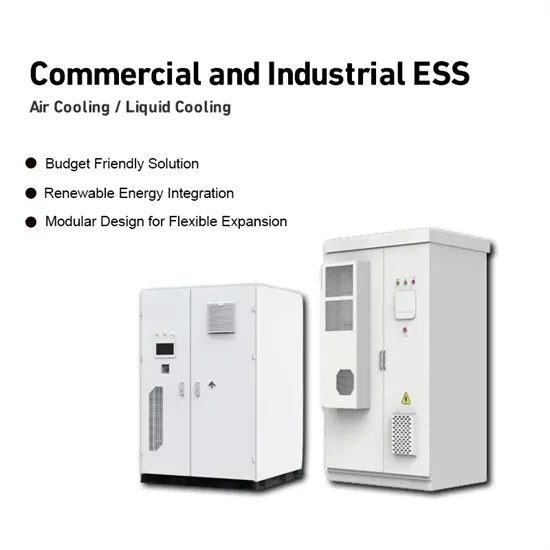

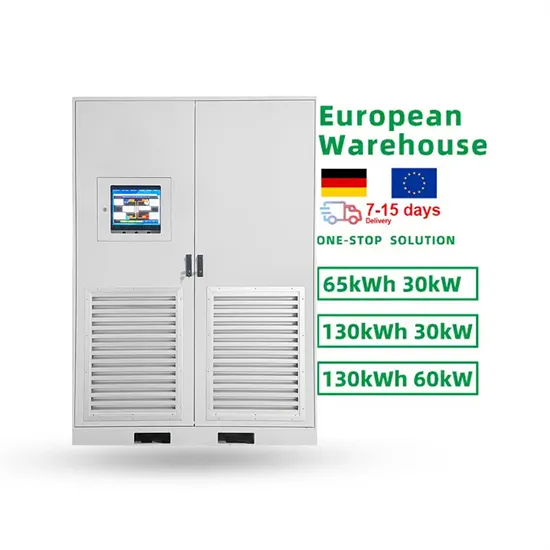

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.